Ceramic substrate green tape and manufacturing method and device thereof

A ceramic substrate and manufacturing method technology, applied in the field of ceramic manufacturing, can solve problems such as inability to meet large-volume and high-quality production requirements, product quality deviation, and complicated assembly process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

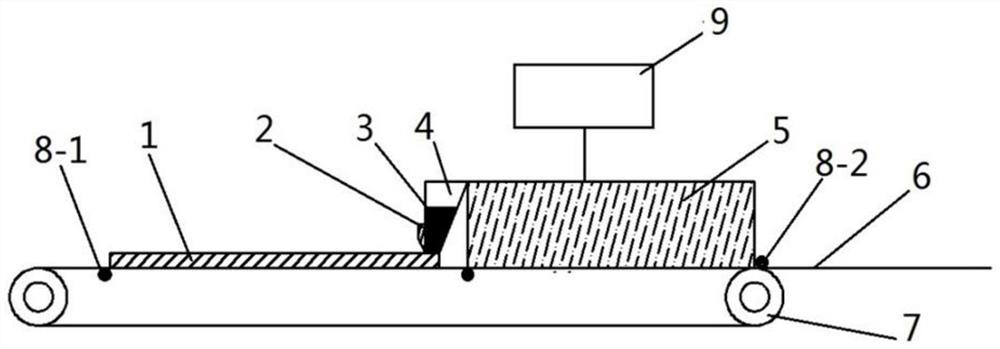

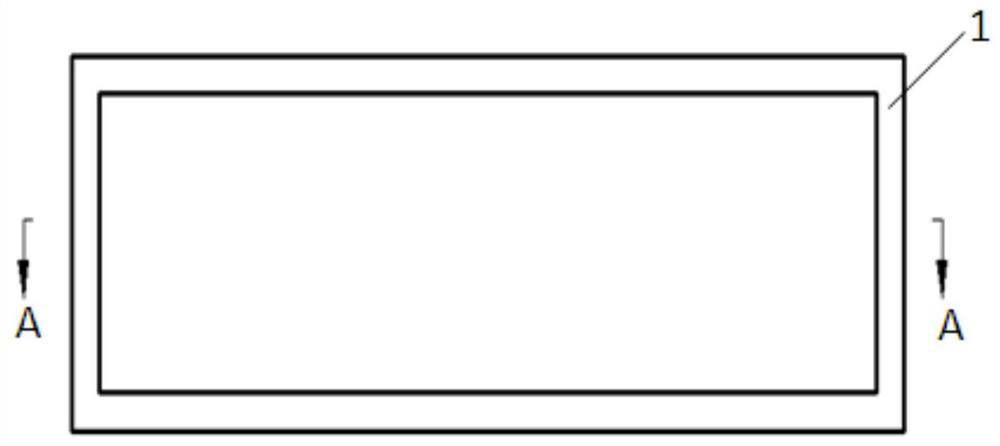

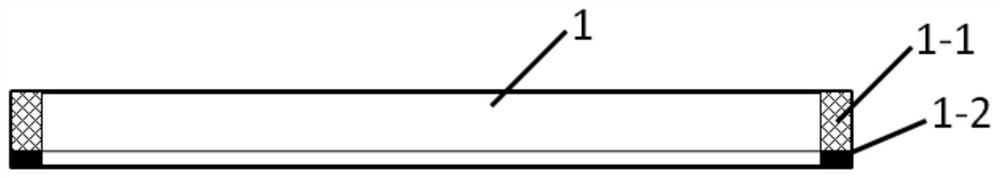

[0035] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, the specific implementation of a ceramic substrate raw tape and its manufacturing method and device according to the present invention will be described below in conjunction with the accompanying drawings and preferred embodiments. Mode, structure, feature and effect thereof are as follows in detail.

[0036] The present invention proposes a method for manufacturing ceramic substrate raw tape, which comprises the following steps: 1) paving ceramic slurry according to the designed size; the ceramic slurry is laid in a single layer; The ceramic slurry is solidified in situ at constant temperature and humidity in an inert atmosphere to obtain a ceramic substrate green tape.

[0037]The ceramic slurry in the technical solution of the present invention adopts the processing technology of sliding material spreading and open belt molding. The c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com