Environment-friendly fireproof insulation plate as well as production equipment and production process thereof

A fireproof insulation board and production equipment technology, applied in the field of building exterior wall insulation materials, can solve the problems of low product strength, unacceptable, and low strength, and achieve the effects of reducing production costs, improving production efficiency, and low thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

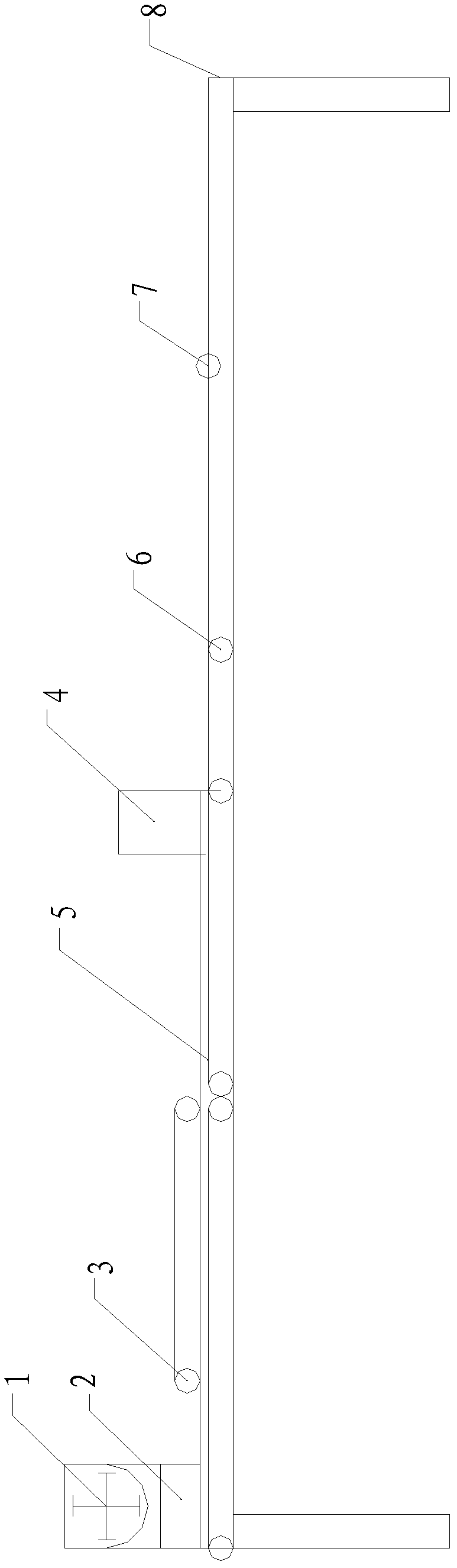

Image

Examples

Embodiment 1

[0023] An environmentally friendly fireproof insulation board is characterized in that it is a block board made of vitrified microbeads, rock wool fibers and water glass according to the order of mixing, paving, continuous flat pressing, online curing, and online cutting. The weight percent of material is as follows:

[0024] Vitrified Beads 45%

[0025] Rock wool fiber 35%

[0026] Liquid Binder 20%

[0027] The particle size of the vitrified microbeads is 0.5-2mm, and the bulk density is 90kg / m 3 , thermal conductivity: 0.038w / m k, refractory temperature: 1000°C, water absorption rate 18%; fiber length of rock wool fiber is 1-15mm, bulk density is 150kg / m 3 , the thermal conductivity is 0.036w / m·k, the refractory temperature is 900°C, and the water absorption rate is 3.9%.

[0028] A process for producing the above-mentioned environmentally friendly fireproof insulation board, comprising a mixer, a paving machine, a continuous flat press, an on-line curing device and an ...

Embodiment 2

[0035] An environmentally friendly fireproof insulation board is characterized in that it is a block board made of vitrified microbeads, rock wool fibers and water glass according to the order of mixing, paving, continuous flat pressing, online curing, and online cutting. The weight percent of material is as follows:

[0036] Vitrified Beads 80%

[0037] Rock wool fiber 15%

[0038] Liquid binder 5%

[0039] The particle size of the vitrified microbeads is 0.5-2mm, and the bulk density is 90kg / m 3 , thermal conductivity: 0.038w / m k, refractory temperature: 1000°C, water absorption rate 18%; fiber length of rock wool fiber is 1-15mm, bulk density is 150kg / m 3 , the thermal conductivity is 0.036w / m·k, the refractory temperature is 900°C, and the water absorption rate is 3.9%.

[0040] A process for producing the above-mentioned environmentally friendly fireproof insulation board, comprising a mixer, a paving machine, a continuous flat press, an on-line curing device and an o...

Embodiment 3

[0047] An environmentally friendly fireproof insulation board is characterized in that it is a block board made of vitrified microbeads, rock wool fibers and water glass according to the order of mixing, paving, continuous flat pressing, online curing, and online cutting. The weight percent of material is as follows:

[0048] Vitrified microbeads 62.5%

[0049] Rock wool fiber 25%

[0050] Liquid binder 12.5%

[0051] The particle size of the vitrified microbeads is 0.5-2mm, and the bulk density is 90kg / m 3 , thermal conductivity: 0.038w / m k, refractory temperature: 1000°C, water absorption rate 18%; fiber length of rock wool fiber is 1-15mm, bulk density is 150kg / m 3 , the thermal conductivity is 0.036w / m·k, the refractory temperature is 900°C, and the water absorption rate is 3.9%.

[0052] A process for producing the above-mentioned environmentally friendly fireproof insulation board, comprising a mixer, a paving machine, a continuous flat press, a curing device and a cut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com