Manipulator for mounting and hoisting automobile rear seat

A technology for rear seats and manipulators, applied in manipulators, metal processing, metal processing equipment, etc., can solve the problems of low degree of automation, high labor intensity of operators, and inability to meet the production cycle of vehicle assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

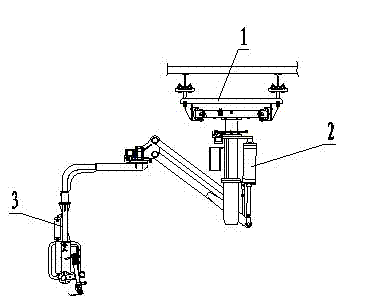

[0028] See Figure 1, Figure 4, Figure 10 , the present invention comprises two parts symmetrically arranged left and right, wherein each part comprises a walking guide rail system 1, a host part 2 and a clamp part 3, and the host part 2 is installed between the travel guide rail system 1 and the clamp part 3, and it consists of a platform The trolley 2-1, the main arm and the locking mechanism, the trolley 2-1 is assembled with the walking rail system 1, and the main arm includes the vertical arm 2-3, the main arm 2-5 and the secondary The arm bar 2-7 is provided with a locking mechanism at the junction of the trolley 2-1 and the main arm, the junction of the main arm 2-5 and the secondary arm 2-7, and the junction of the main arm and the clamp part 3.

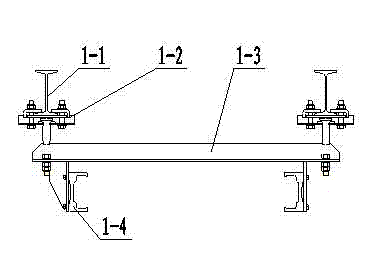

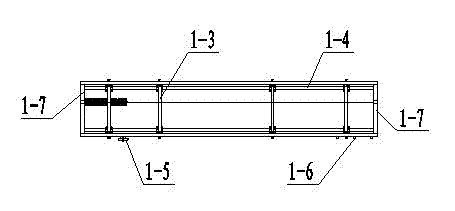

[0029] See Figure 1, figure 2 , the walking guide rail system 1 of the present invention includes an I-shaped steel base part 1-1, an I-shaped steel hanging structure part 1-2, a rigid rail hanging structure part 1-3 and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com