Gaugeable star-shaped valve

A star valve, quantity technology, applied in conveyors, rotary conveyors, transportation and packaging, etc., can solve the problem that star valves cannot be measured, and achieve the effect of strong adaptability and large measurement range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

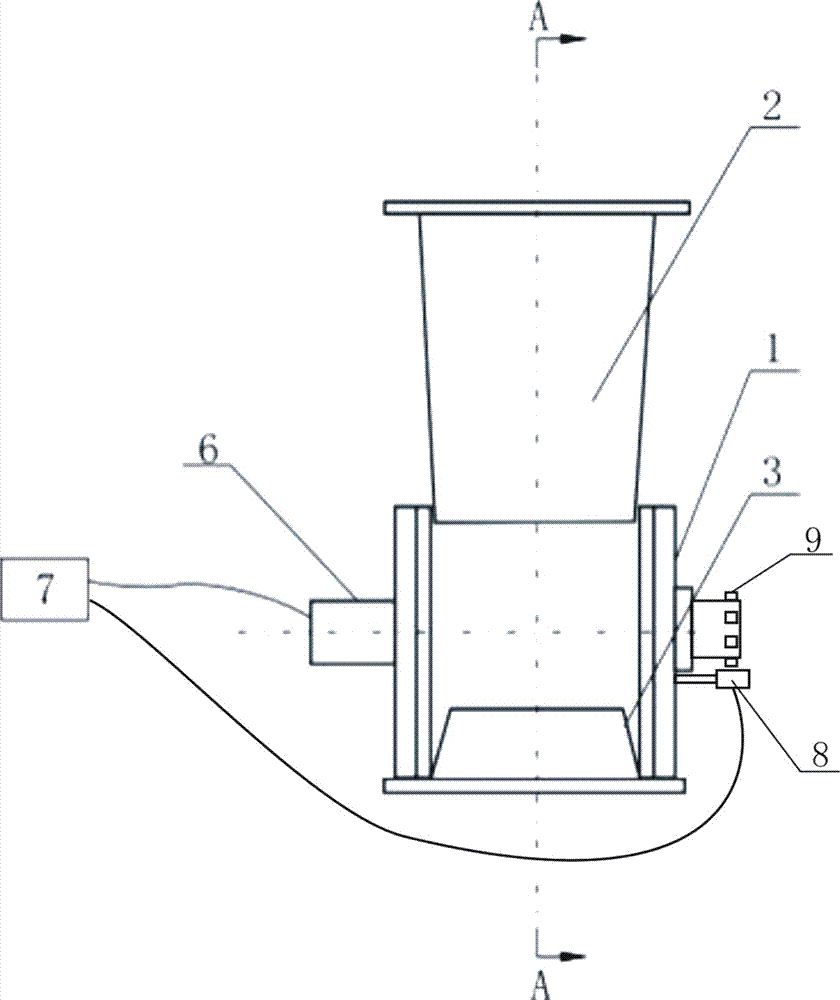

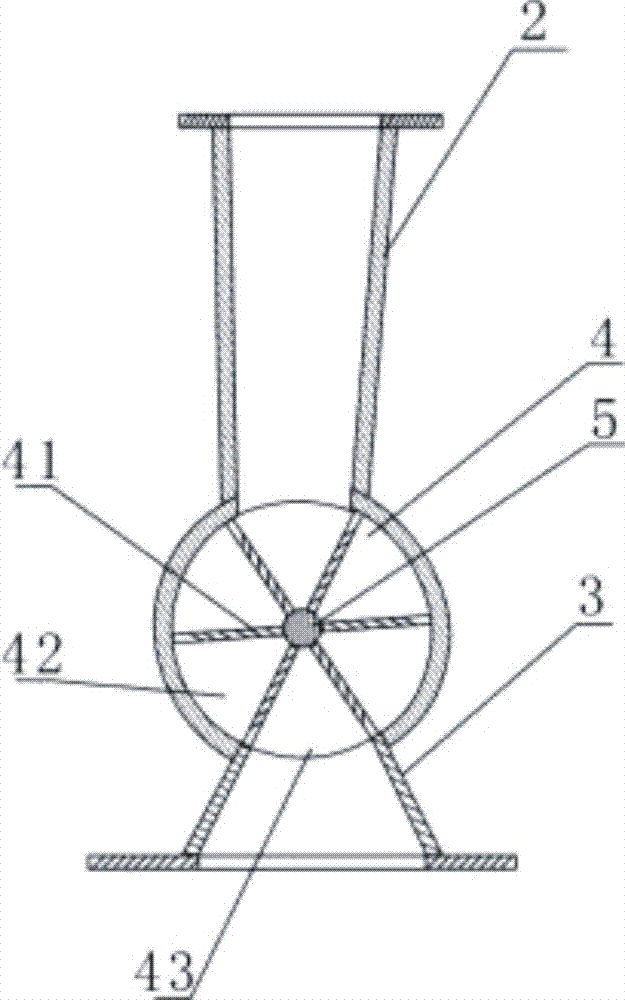

[0012] Such as figure 1 and figure 2 As shown, the meterable star valve includes a discharge valve housing (1), a feed pipe (2) located at the upper part of the housing (1), a discharge pipe (3) located at the lower part of the housing (1) and The impeller (4) located in the housing and the rotating shaft (5) driving the impeller (4); the impeller (4) has six blades ( 41 ), and the blades ( 41 ) divide the impeller ( 4 ) into equal-sized The number of grids (42) equal to the number of blades (41); the size of the opening (43) of the (42) grid is equal to or greater than the size of the inlet of the discharge pipe (3); the axis of rotation (5) along the There are permanent magnets (9) with the same number as the blades (41) and corresponding positions evenly distributed on the circumference; a reed switch (8) matched with the permanent m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com