Heavy multifunctional combined supporting frame

A multi-functional combination and support frame technology, which is applied to pillars, building types, theaters, etc., can solve the problems of waste of support frame resources, non-universal support frames, and high costs, so as to save installation and disassembly costs, fast installation and dismantling, and interoperability. Strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings, so that those of ordinary skill in the art can implement it after referring to this specification.

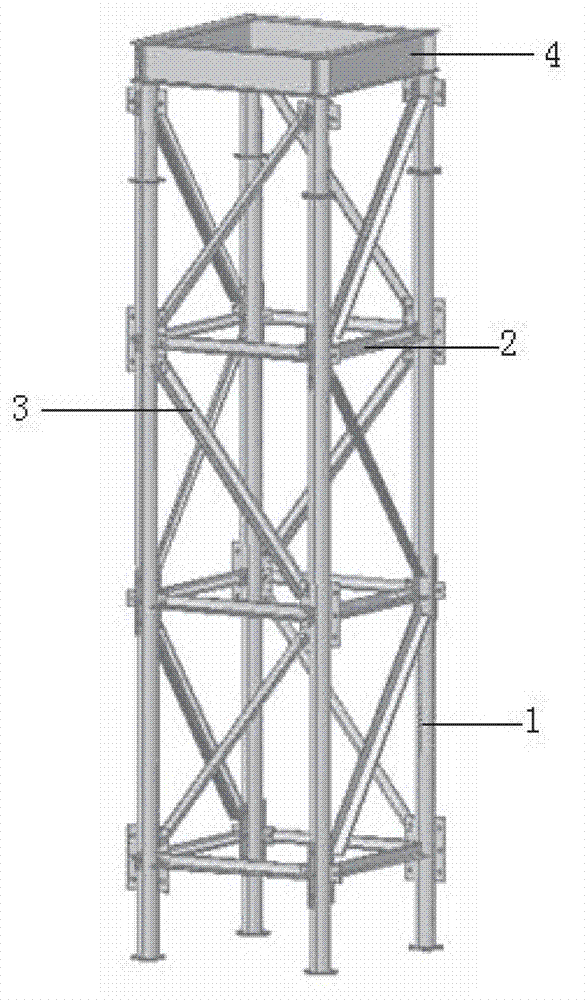

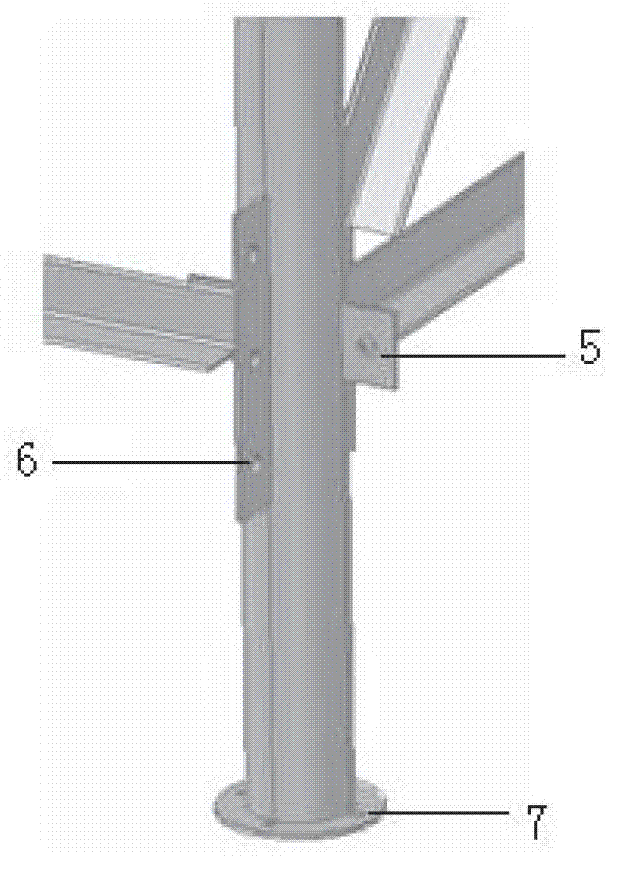

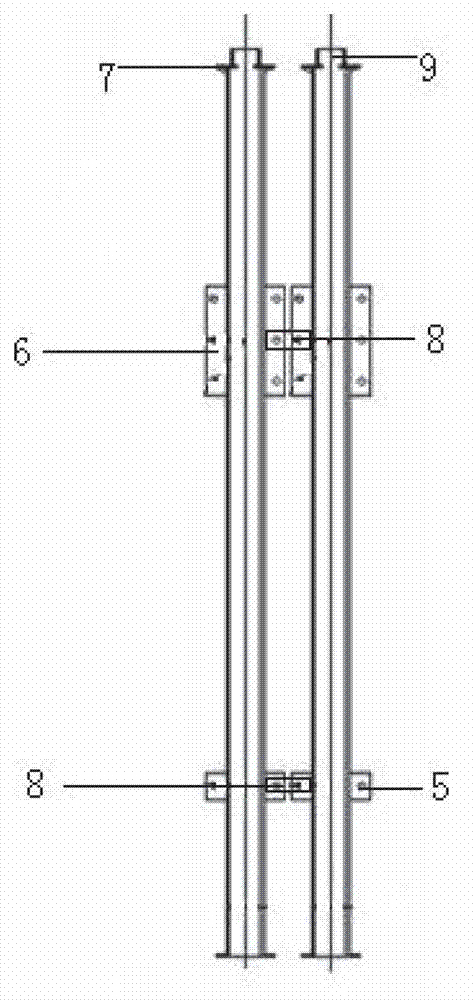

[0035] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, a kind of heavy-duty multi-functional combined supporting frame of the present invention comprises: column 1, at least one connecting structure is welded on its outer wall; In the connection structure, a plurality of rectangular structures are formed with the column 1; the oblique rod 3 is detachably connected to the connection structure on the diagonal of the rectangular structure, and two adjacent oblique rods 3 are in the The two non-parallel diagonals of the rectangular structure extend; the supporting beam 4 is connected to the top of the column 1 . The column 1 is a round steel pipe, a square steel pipe or an H-shaped steel pipe, preferably a round steel pipe. The outer side of the column 1 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com