Combined advanced drilling exploration method for detecting water-free dissolving cavity and water dissolving cavity in tunnel

A water-soluble cavity and tunnel technology, which is applied in tunnels, surveys, earthwork drilling and mining, etc., to achieve the effect of simple methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

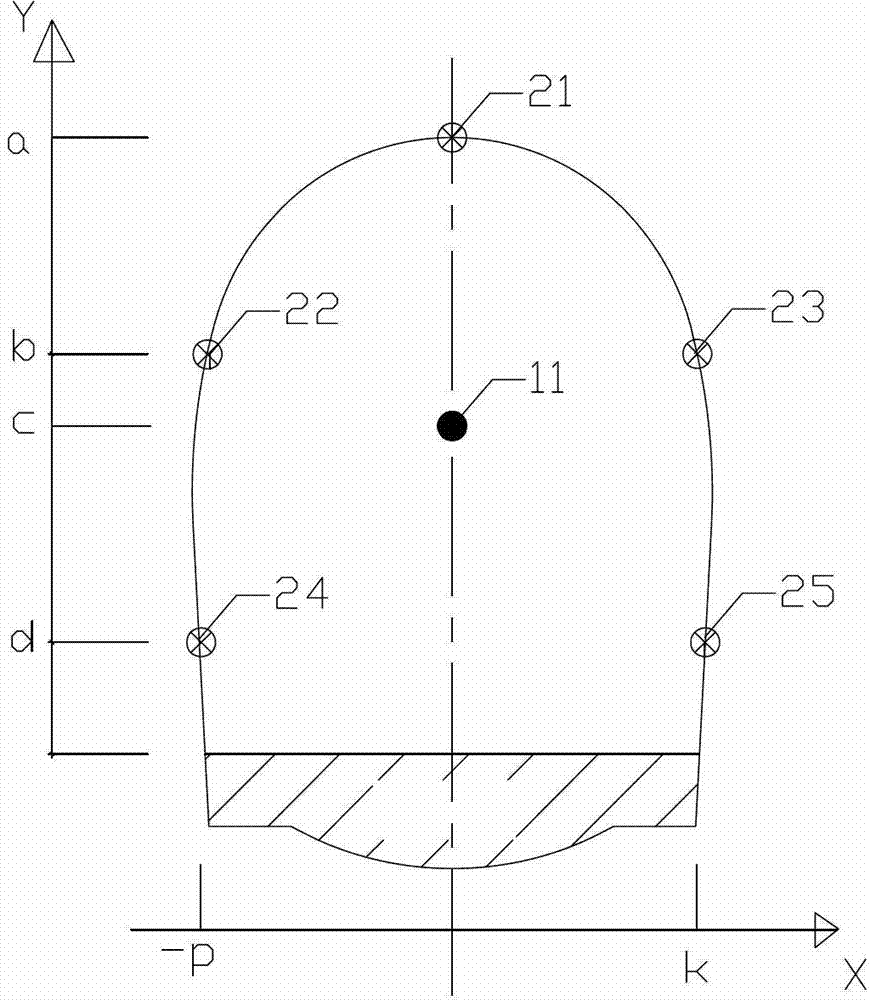

[0041] combine figure 1 , 2 And the combined drilling method of table 1,2,3 detection general karst section, this method comprises the following steps:

[0042] 1) Firstly, according to the geological survey results, comprehensively analyze and judge the karst development in front of the tunnel and the possible geological risks, and carry out construction geological advance forecast classification;

[0043] 2) Drill hole A ahead of time in the direction of the tunnel to be excavated. In the process of drilling hole A, when the drill bit penetrates the solution cavity and reaches 5m of the complete bedrock, stop drilling, or when the drill bit drills to the bottom and still has no Stop drilling when drilling through the solution cavity;

[0044] 3) Drill 5 drilling holes along the face of the tunnel facing the direction of the tunnel to be excavated, and then excavate the tunnel forward under the protection of the safety rock plate of the drilling holes. Stop tunneling when ...

Embodiment 2

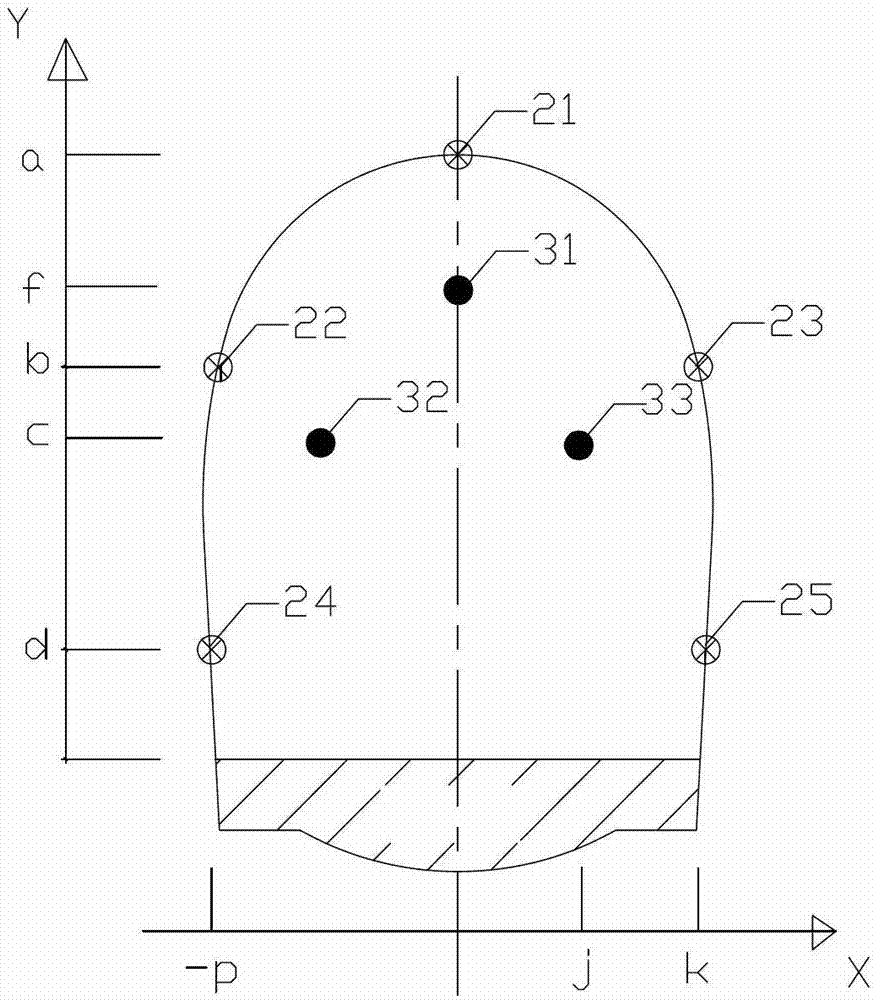

[0050] combine image 3 , 4And table 1, 2, 3 detect the combined drilling method of karst more developed section, this method comprises the following steps:

[0051] 1) Do a good job in the relevant preparations for drilling water out, prevent the drilling from flooding the tunnel, and install the orifice pipe;

[0052] 2) Drill 3 exploration holes A ahead of the tunnel facing the direction of the tunnel to be excavated, and stop drilling when the water comes out of the dissolution cavity;

[0053] 3) Install a high-pressure water stop valve and a pressure gauge on the probe hole A, and seal the hole after monitoring the water pressure change in the borehole;

[0054] 4) Drill 11 drilling holes along the face of the tunnel facing the direction of the tunnel to be excavated, and then excavate the tunnel forward under the protection of the safety rock plate of the drilling holes. The drilling holes and excavation tunnels are cycled until the drilling holes Stop tunneling when...

Embodiment 3

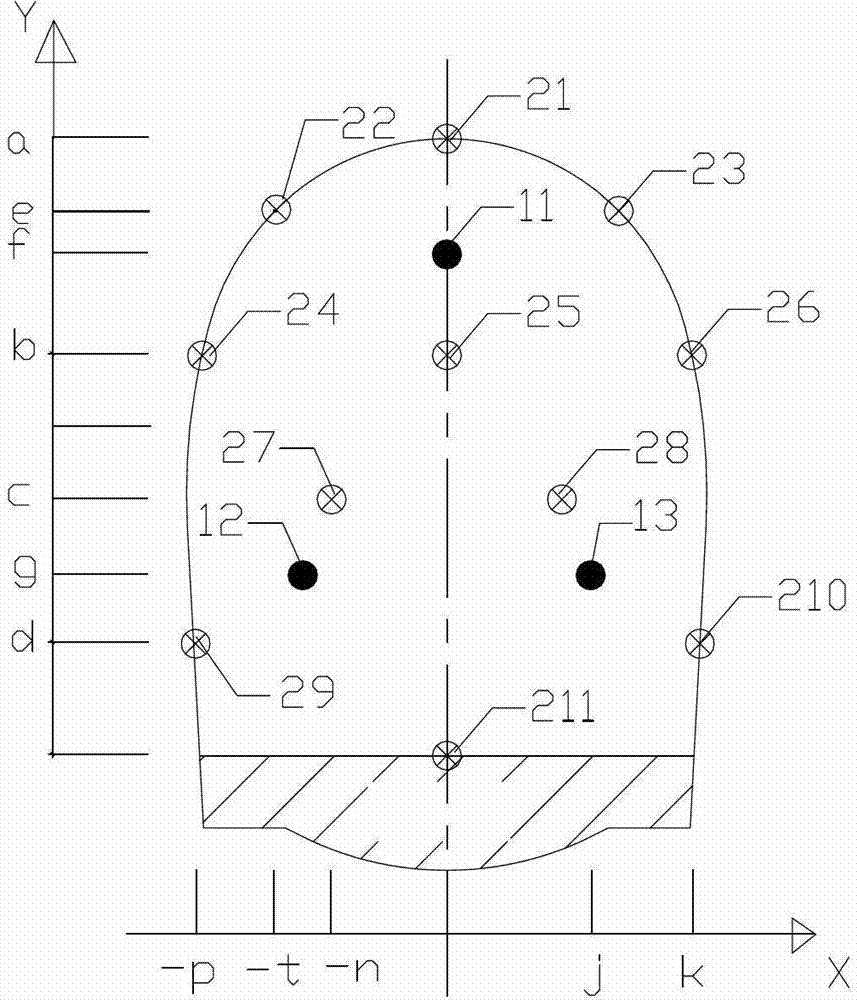

[0062] combine Figure 5 , 6 And the combined drilling method of table 1, 2, 3 detection karst development section water-bearing solution cavity, it is characterized in that, this method comprises the following steps:

[0063] 1) Do a good job in the relevant preparations for drilling water out, prevent the drilling from flooding the tunnel, and install the orifice pipe;

[0064] 2) Drill 5 exploration holes A ahead of the tunnel facing the direction of the tunnel to be excavated, and stop drilling when the water comes out of the dissolution cavity;

[0065] 3) Install a high-pressure water stop valve and a pressure gauge on the probe hole A, and seal the hole after monitoring the water pressure change in the borehole;

[0066] 4) Drill 17 drilling holes along the face of the tunnel facing the direction of the tunnel to be excavated, and then excavate the tunnel forward under the protection of the safety rock plate of the drilling holes. Stop tunneling when the edge of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com