Aircraft engine cowl and process therefor

An aero-engine and fairing technology, applied in the field of fairing, can solve the problems of unfavorable inspection and maintenance of the weight core fairing, and achieve the effects of reducing the overall nacelle weight, reducing maintenance costs, and reducing the weight of the engine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

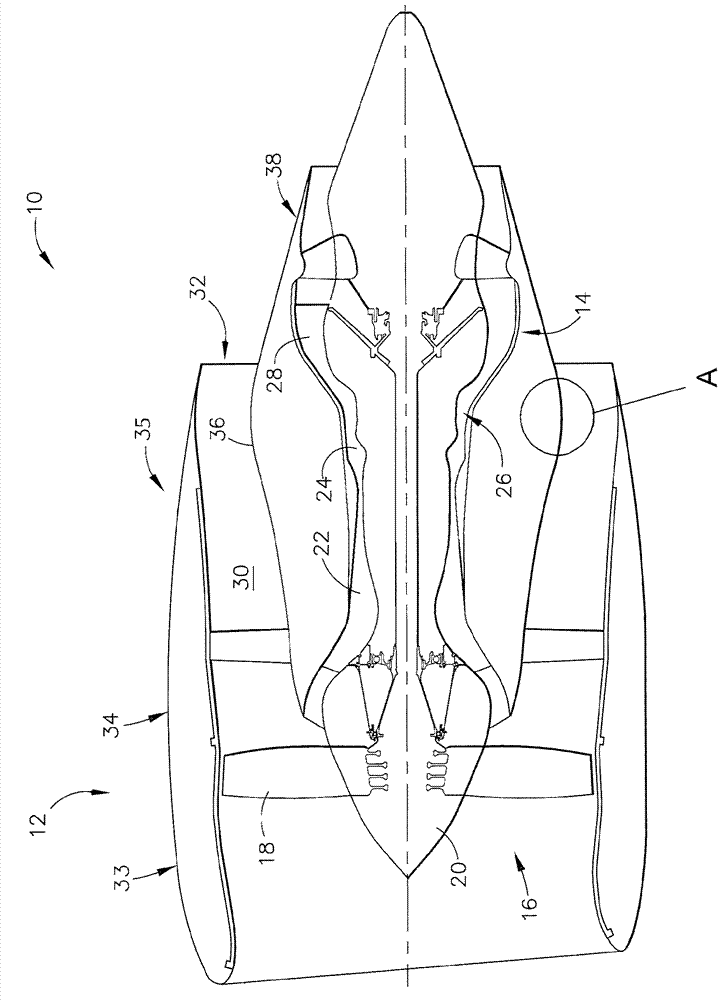

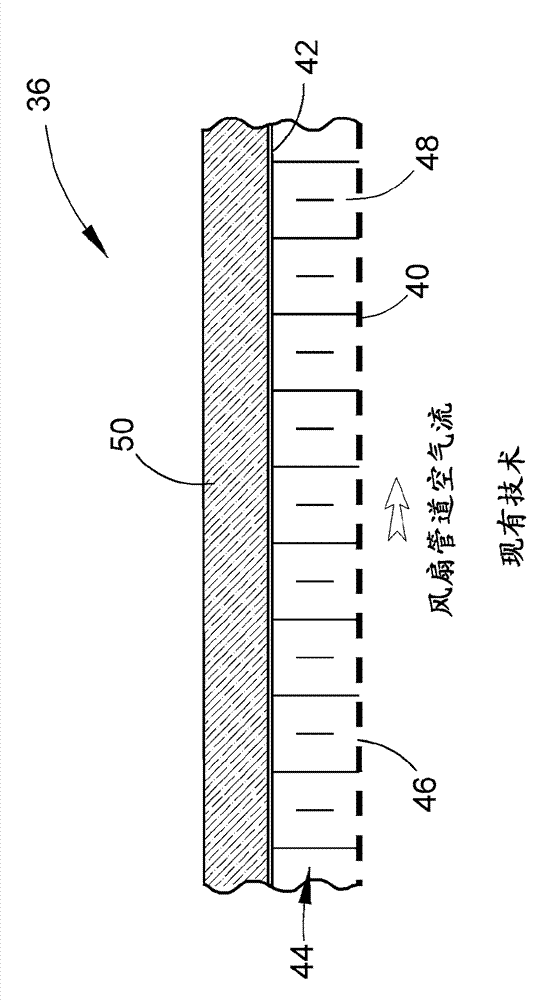

[0050] image 3 Shown are suitable for use in for example figure 1 A cross-section of a core cowling 136 used in a high-bypass gas turbine engine of the type shown in FIG. image 3 The fairing 136 shown in can be installed instead of figure 2 The core fairing 36, and is therefore particularly suitable for enclosing the core module 14 and defining figure 1 The inner boundary of the bypass duct 30 of the engine 10 is shown in .

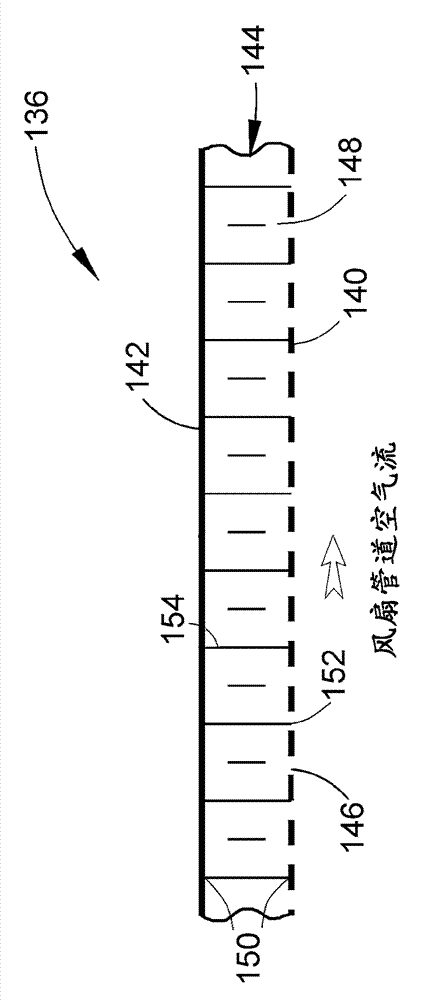

[0051] and figure 2 Similar to the prior art fairing 36, image 3 The fairing 136 shown in has a layered structure including skins 140 and 142 attached to a core component 144 . The cowling 136 is intended to be installed so that the skin 140 faces the air flow through the bypass duct 30 of the engine 10, and for this purpose the skin 140 is made as an acoustic skin 140 with a well-defined pattern determined by satisfying the specific acoustic Small and preferably equidistantly spaced perforations or holes 146 are formed. The holes 146 extend c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com