Six-unit tile-shaped plug nozzle cold flow test device

A cold flow test, plug nozzle technology, applied in jet propulsion devices, rocket engine devices, machines/engines, etc., can solve problems such as limited test content, and achieve the effects of reasonable test results, simple structure, and wide research scope.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with accompanying drawings and examples.

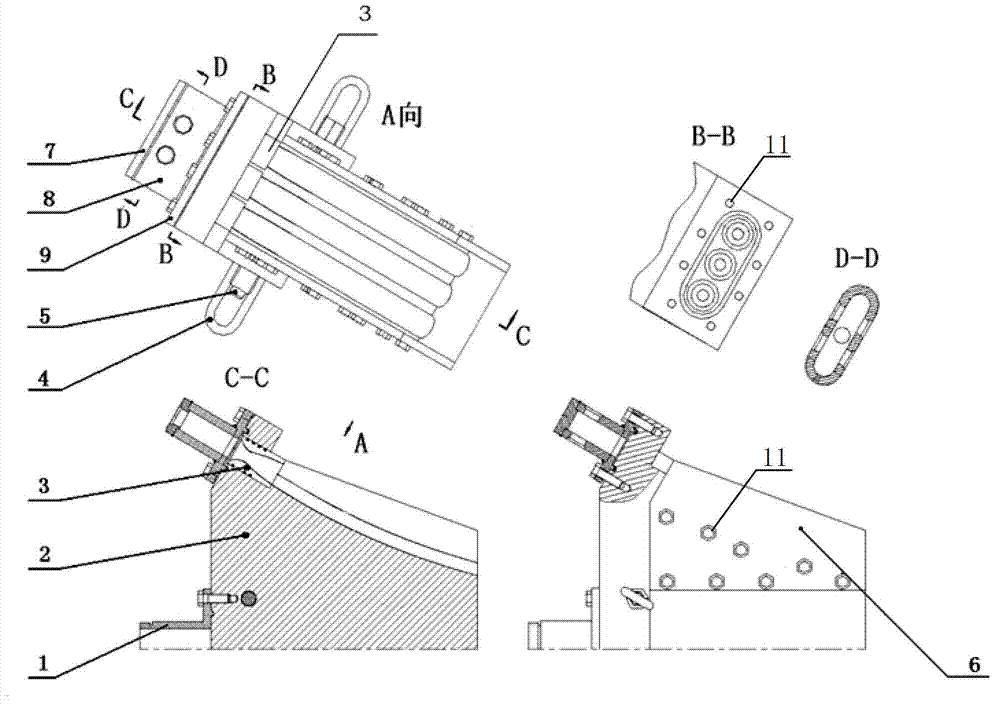

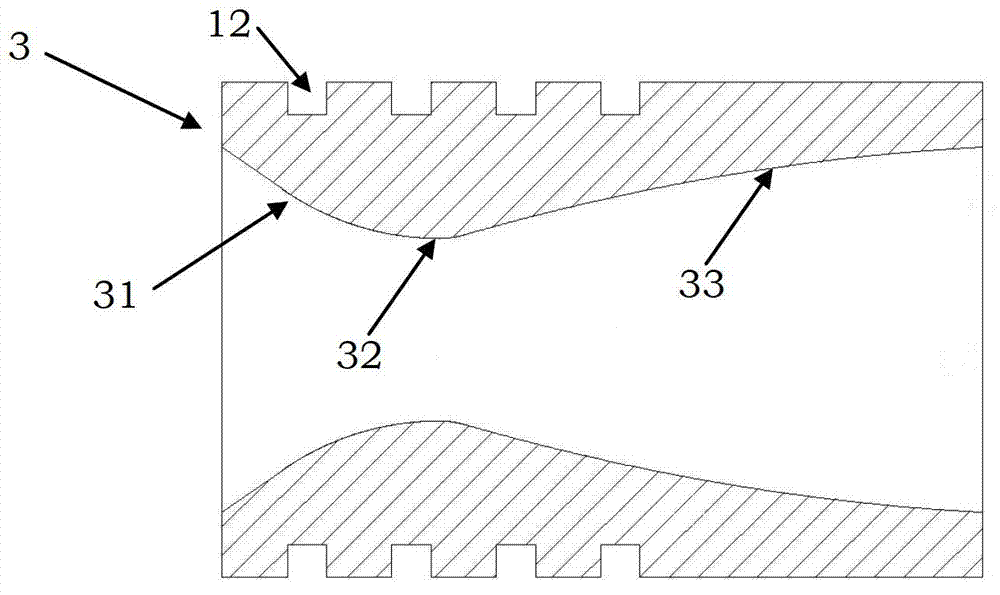

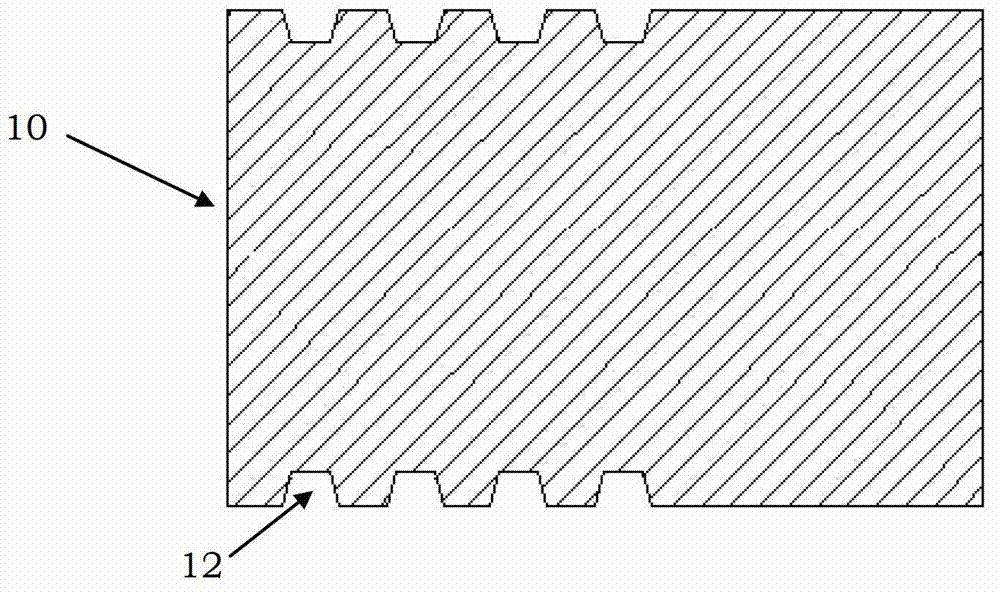

[0026] Such as figure 1 As shown, the present invention provides a six-unit "tile"-shaped plug nozzle cold flow test device, which mainly includes: plug nozzle assembly, boom assembly, combustion chamber assembly and measurement assembly. The plug nozzle assembly includes: plug cone 2 and six unit inner nozzles 3, such as figure 1 Shown in the C-C section in. The boom assembly includes: boom 4 and boom nut 5, such as figure 1 A in Fig. Combustion chamber assembly comprises combustion chamber top cover 7, combustion chamber 8 and combustion chamber floor 9, as figure 1 A in Fig. Measurement components include thrust sensors, combustion chamber pressure sensors and vacuum pressure sensors.

[0027] In the embodiment of the present invention, figure 1 Figure A in the figure shows a schematic diagram of the left or right side of the plug cone 2, and C-C sho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com