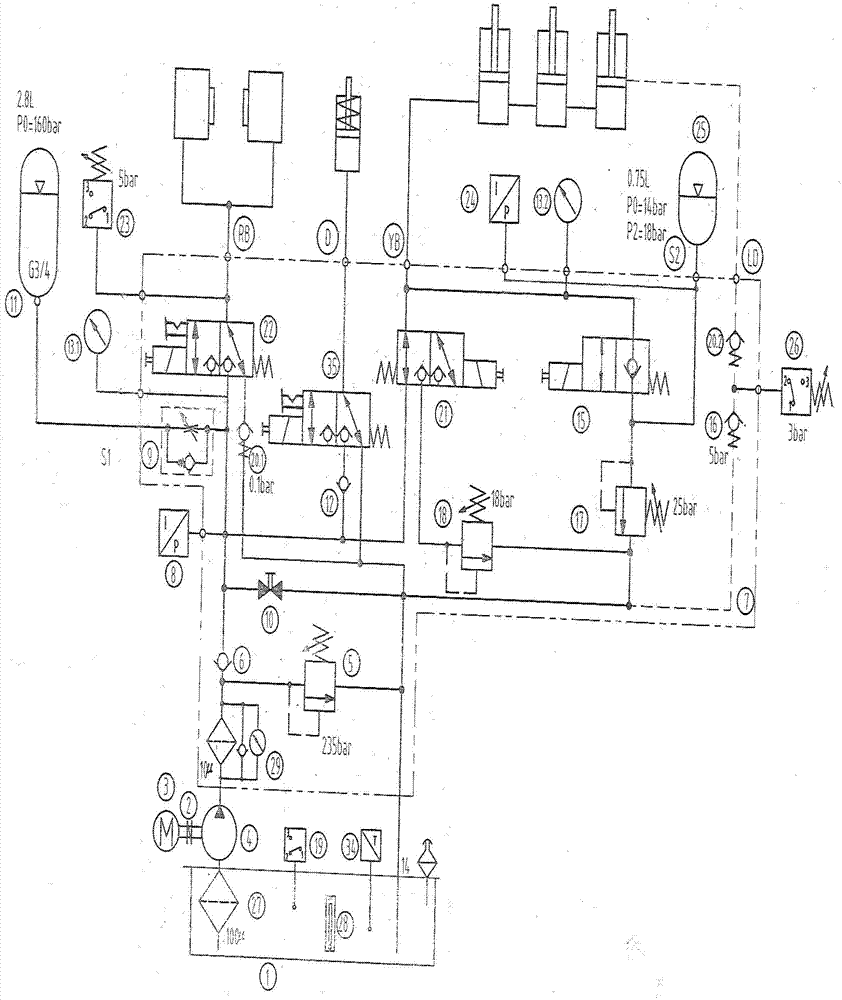

Yawing and hub braking hydraulic system for wind driven generator set

A technology of wind turbines and brake hydraulics, which is applied in the control of wind turbines, wind turbines, wind power generation, etc. It can solve problems such as internal leakage of damage, shortening of system pressure holding time, seal damage, etc., and achieve the effect of eliminating system heat generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The specific embodiment of the present invention is: when the wind power generating set is in normal operation, all solenoid valves of the present invention are in the state shown in the figure, and their electromagnets are not electrified, and the hydraulic system will not be overheated due to the heating caused by the electromagnets being electrified. temperature; when the yaw is required, the main console issues an instruction, the No. 21 solenoid valve is energized and reversed, and the three yaw brake cylinders are connected to the oil return. They are damped by the 18bar back pressure established by the back pressure relief valve 18. Under the action, it is driven by the yaw drive mechanism to rotate smoothly and center the wind direction. In this process, as long as the pressure between the three brake cylinders and the overflow valve 18 is lower than the holding pressure in the accumulator 25, the pressure oil in the accumulator 25 will automatically open the zer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com