LED floodlight using the lamp housing as the bracket structure of the installation interface

A technology of LED floodlights and installation interface, which is applied to the components of lighting devices, cooling/heating devices of lighting devices, light sources, etc., and can solve problems such as inconvenient use, few batches, and high maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

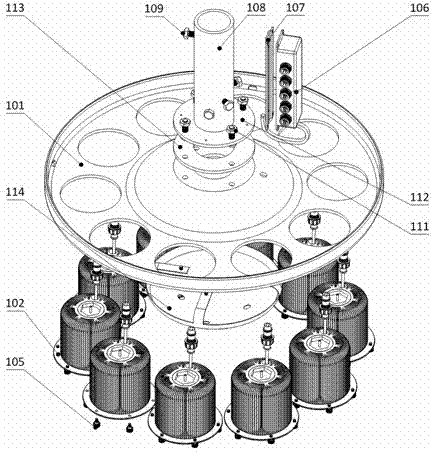

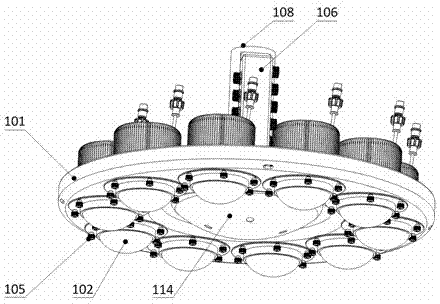

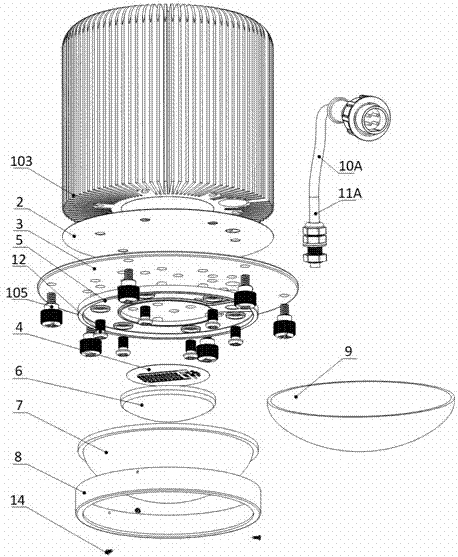

[0060] Example 1. An LED floodlight using a lamp housing as an installation interface support structure, such as figure 1 , figure 2 and Figure 24 As shown, it includes a lamp housing 101 stamped and formed by a metal plate through a stamping process. There is an installation interface on the lamp housing 101, and an LED bulb 102 with a heat sink is provided on the installation interface. The middle part of the lamp housing 101 is connected by a lamp pole fixing piece. The light pole fixing sleeve 108 and the bottom of the light housing 101 are provided with a decorative cover 114 . The lamp housing 101 is circular, and the central top of the lamp housing 101 is provided with a group of ring-shaped installation interfaces around the lamp pole fixing sleeve 108. The edge of the lamp housing 101 is provided with folded edges to increase the structural strength; Decorative cover 114; the installation interface includes a surface and a connection hole that are in contact...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com