Solid-particle air heat absorber used for solar thermal power plant

A solid particle, solar thermal technology, applied in solar thermal power generation, solar thermal collectors, solar thermal collectors using working fluid, etc. Problems such as poor air flow stability, to achieve the effect of extending service life, high radiation absorption rate, and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

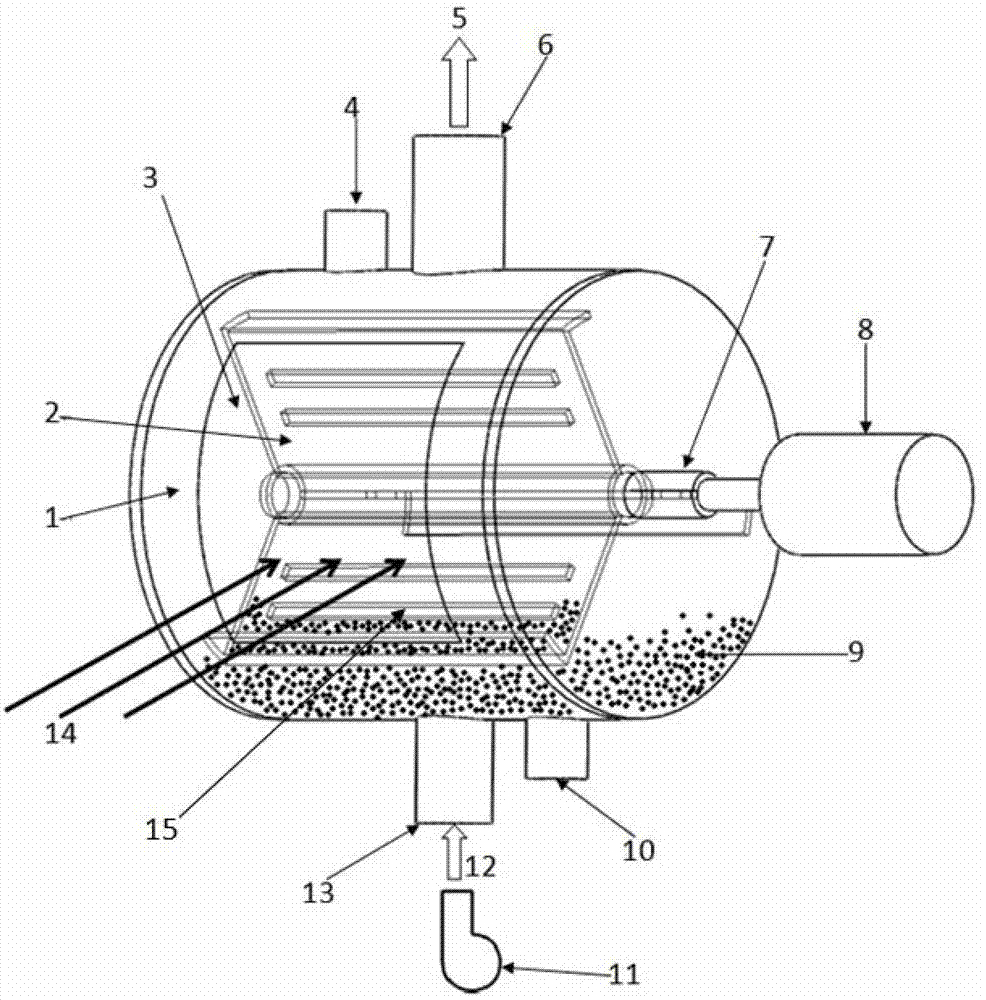

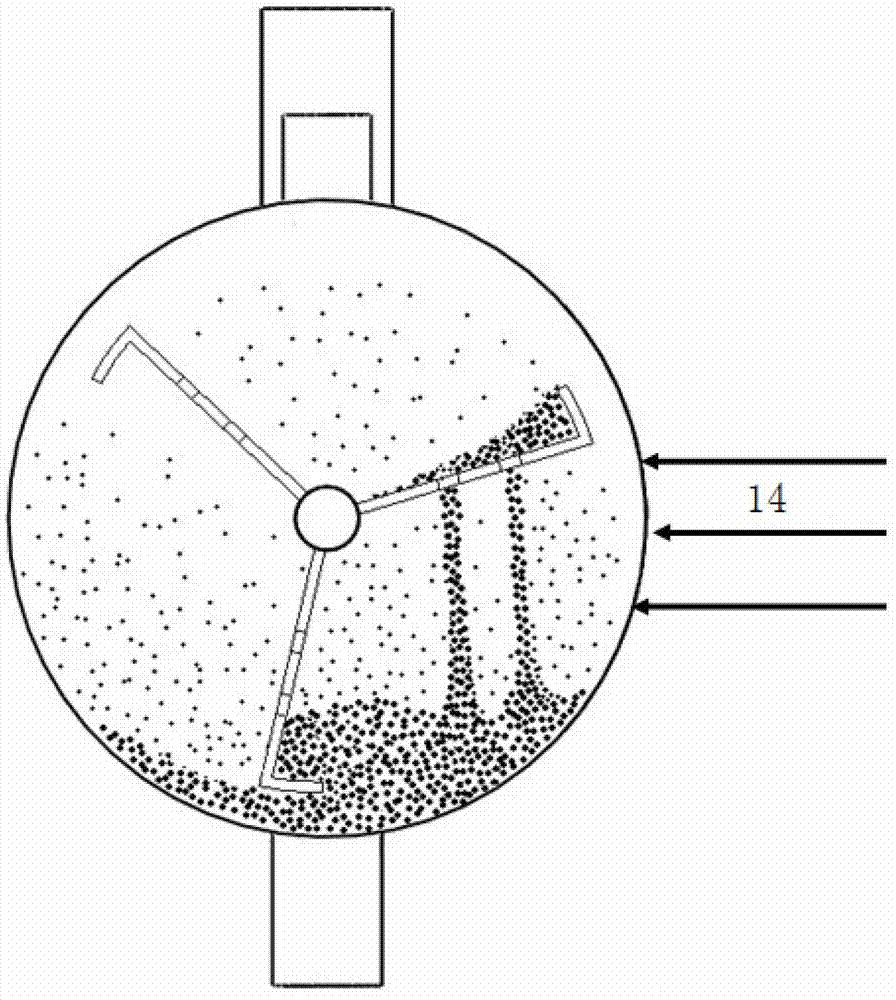

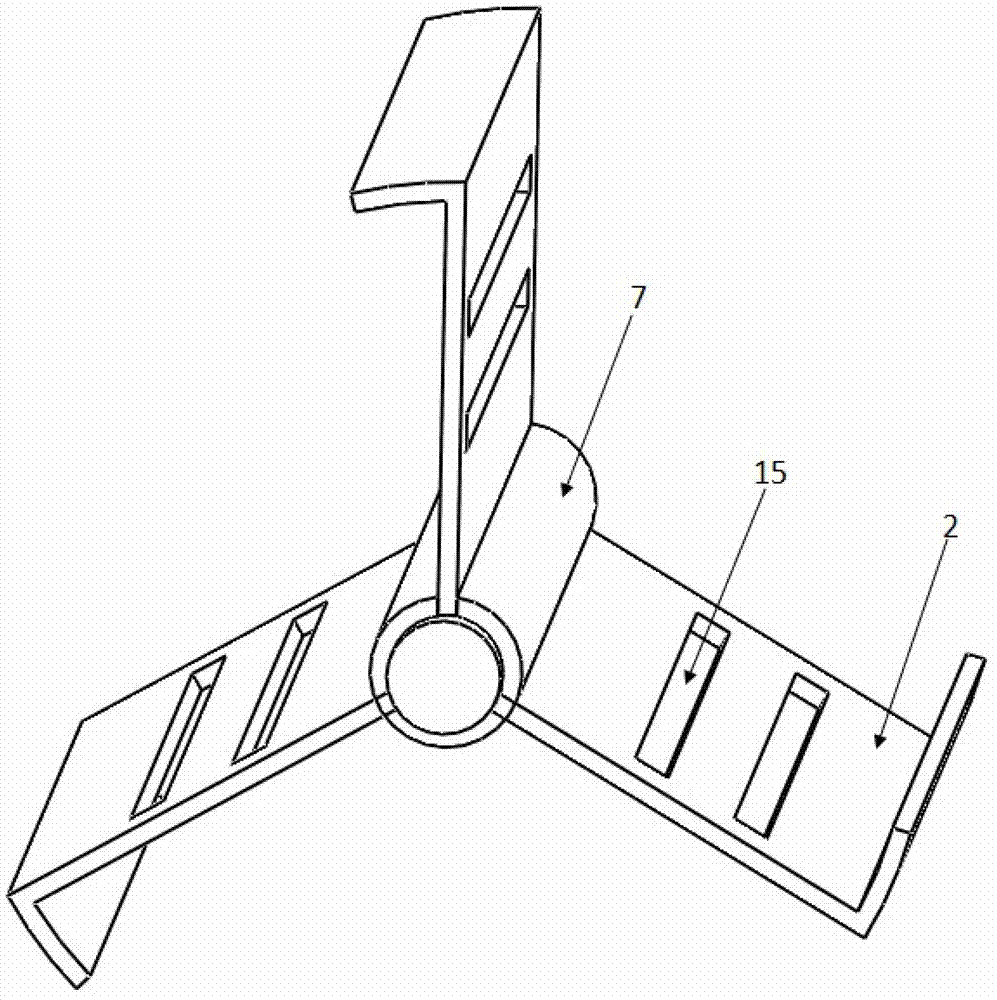

[0017] figure 1Shown is the rotary stirring solid particle air heat absorber of the present invention. The heat absorber is composed of a heat absorber cavity 1 , a stirring blade 2 , a transparent window 3 , a feed inlet 4 , an air outlet 6 , a spindle 7 , solid particles 9 , a discharge outlet 10 , and an air inlet 13 . The heat absorber cavity 1 is cylindrical or other shapes, and is made of high temperature resistant materials. The light-transmitting window 3 is a part of the heat absorber cavity 1 and is located on the side of the heat absorber cavity 1 facing the projection of the concentrated radiant energy flow 14 . The light-transmitting window 3 is usually made of quartz glass, and is used to project the concentrated radiation energy flow 14 into the interior of the heat absorber. The connection between the light-transmitting windo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com