High-temperature and high-voltage resistance subsection capacitive level transmitter

A segmented capacitance and high temperature resistant technology, applied in the liquid level indicator for physical variable measurement, etc., can solve the problems of easy differences in medium characteristics, complex sealing, damage, etc., to increase selectivity and convenience, and increase sealing safety. The effect of improving the measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

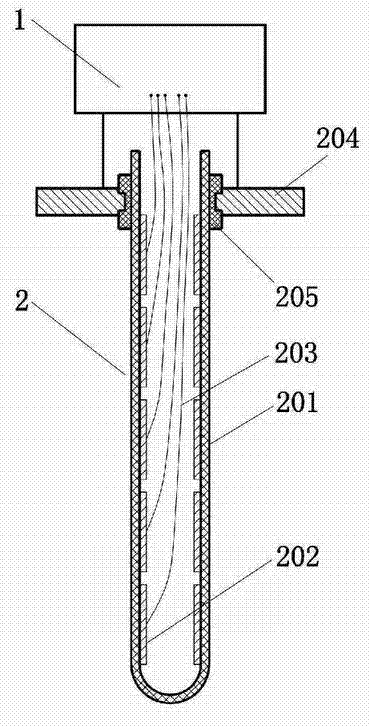

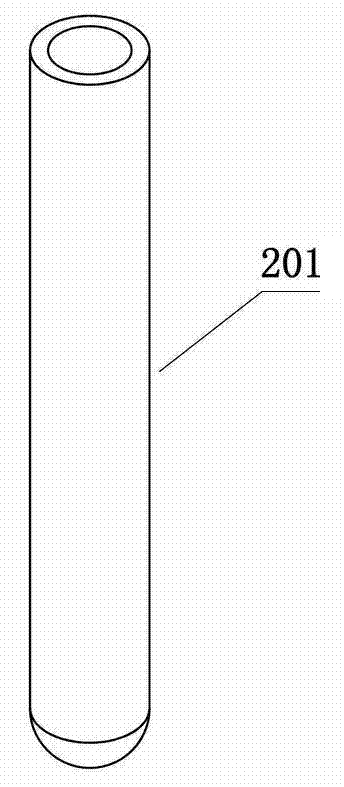

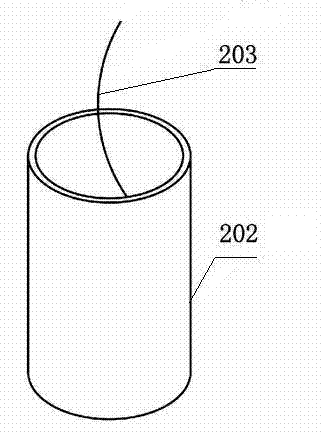

[0025] Such as figure 1 As shown, the present invention is a high temperature and high pressure segmental capacitive level transmitter, which is used to measure the height of various material interfaces in containers with extreme environments such as high temperature and high pressure, such as water, oil, and steam interfaces in containers. Wait. This embodiment includes an electrical signal processor 1 and a sensor 2, and the sensor 2 includes a tubular rigid insulating sleeve 201 with one end closed, such as figure 2 shown. Inside the tubular rigid insulating sleeve 201, there are several tubular electrodes 202 with certain heights, flat end surfaces, and mutual insulation from bottom to top that are close to the inner tube wall. The insulation method can be through insulating gaskets or space insulation; The connecting wires 203 to which the electrodes are connected respectively are electrically connected to the electrical signal processor 1 through the inner side of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com