High-precision liquid or gas rocket engine thrust rack

A rocket engine, high-precision technology, used in engine testing, force/torque/work measuring instruments, machine/structural component testing, etc. Improved thrust accuracy, reliable results, reduced interference effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

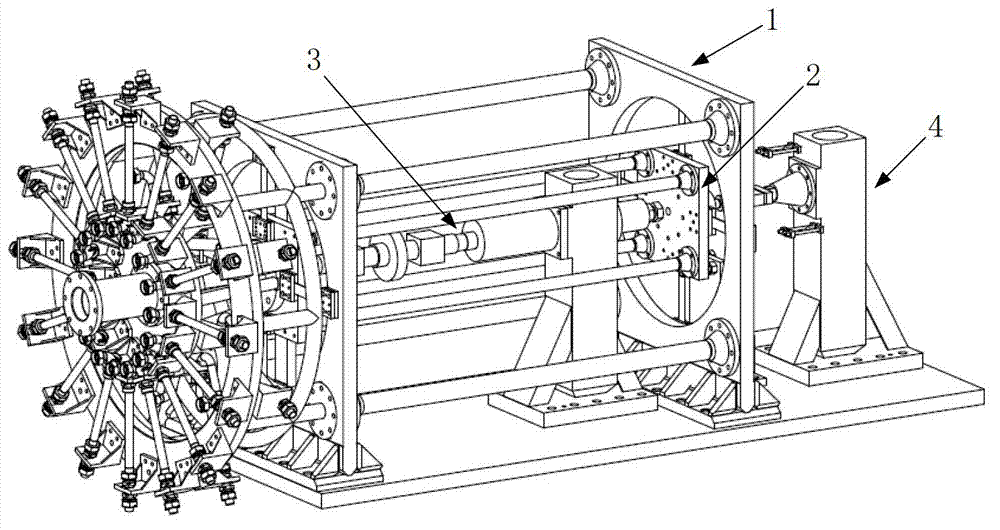

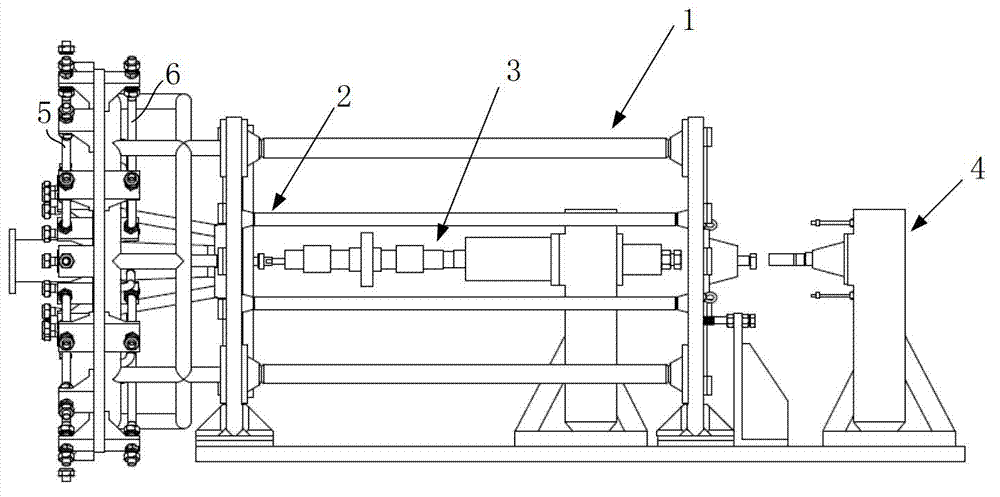

[0049] The present invention is a high-precision liquid or gas rocket engine thrust measuring bench, such as figure 1 , figure 2 As shown, the thrust measurement bench mainly includes a fixed frame assembly 1 , a movable frame assembly 2 , an in-situ thrust calibration assembly 3 and a working thrust measurement assembly 4 .

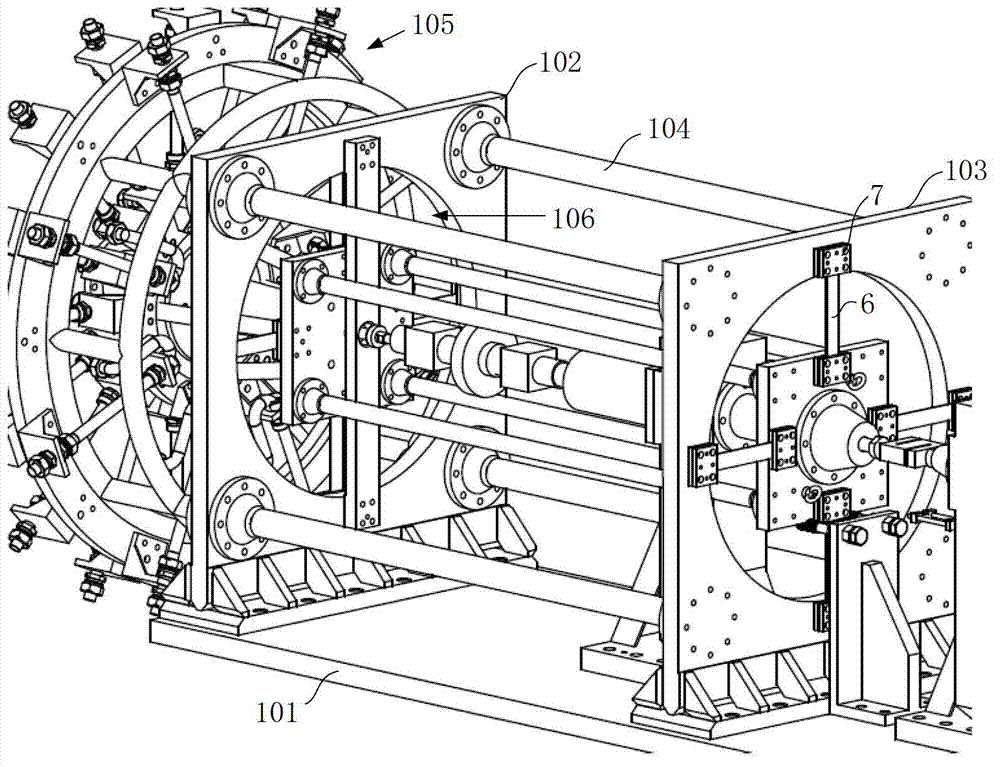

[0050] The fixed frame assembly 1 includes a bottom platform 101, a fixed frame front baffle 102, a fixed frame rear baffle 103, a fixed frame support rod 104 and a fixed frame truss assembly 105, which are used as the support of the entire thrust measuring platform, such as image 3 shown. Wherein, the fixed frame front baffle plate 102 and the fixed frame rear baffle plate 103 are parallel to each other, and are vertically fixed on the bottom platform 101. The bottom platform 101 can reliably weld the thrust measuring bench of the present invention and the saddle of the test vacuum chamber, and During installation, it is necessary to keep the bottom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com