Ultrasonic automatic detection system of tubing with variable wall thickness and step

An automatic detection and variable wall thickness technology, applied in the use of sound waves/ultrasonic waves/infrasonic waves to analyze solids, use sound waves/ultrasonic waves/infrasonic waves for material analysis, and measuring devices, etc., can solve difficult positioning, quantification, positioning, quantitative errors and other issues, to achieve the effect of improving detection efficiency and detection quality, improving product quality, and achieving significant economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

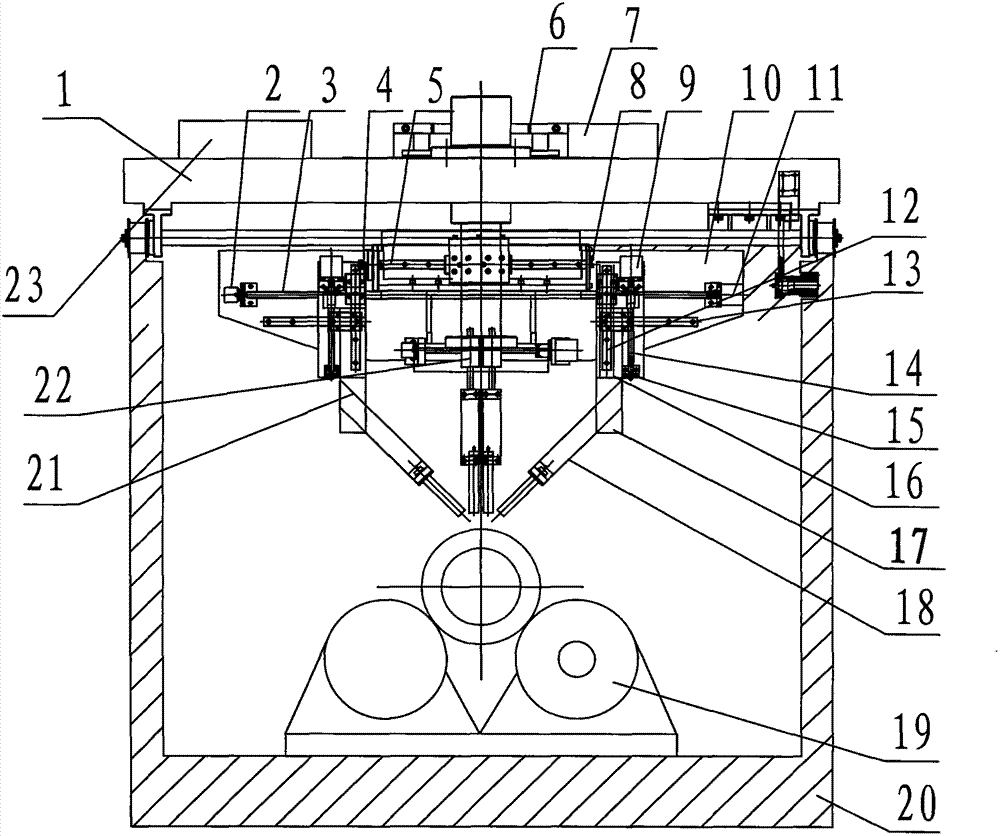

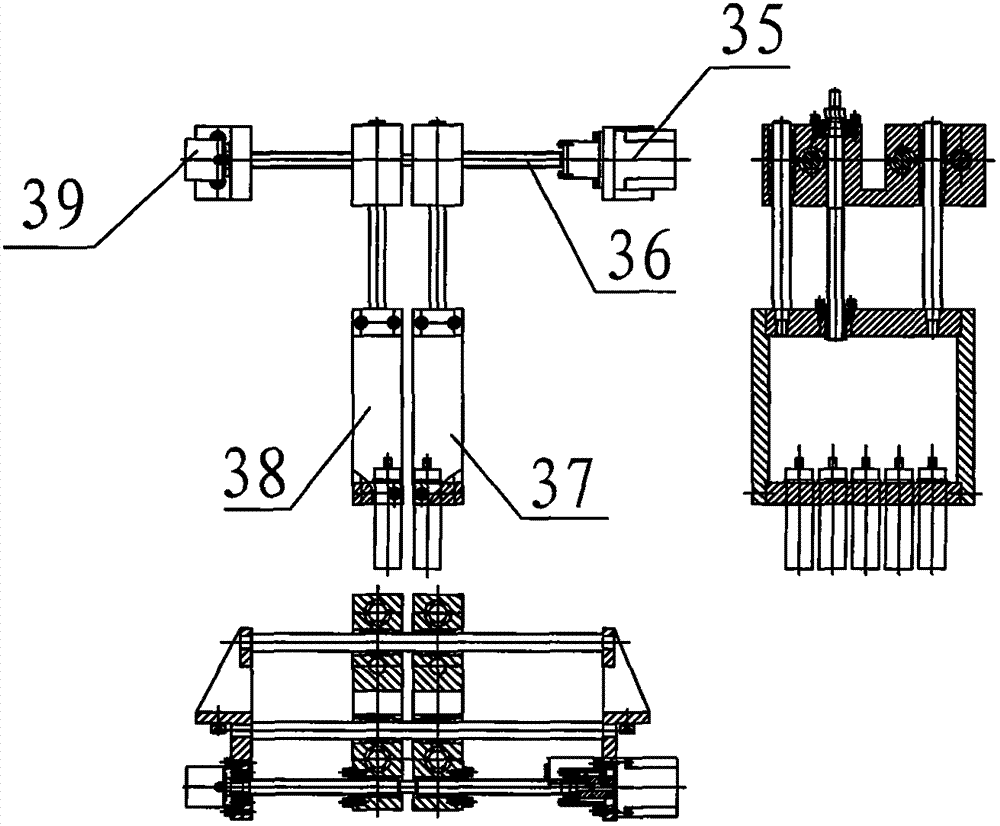

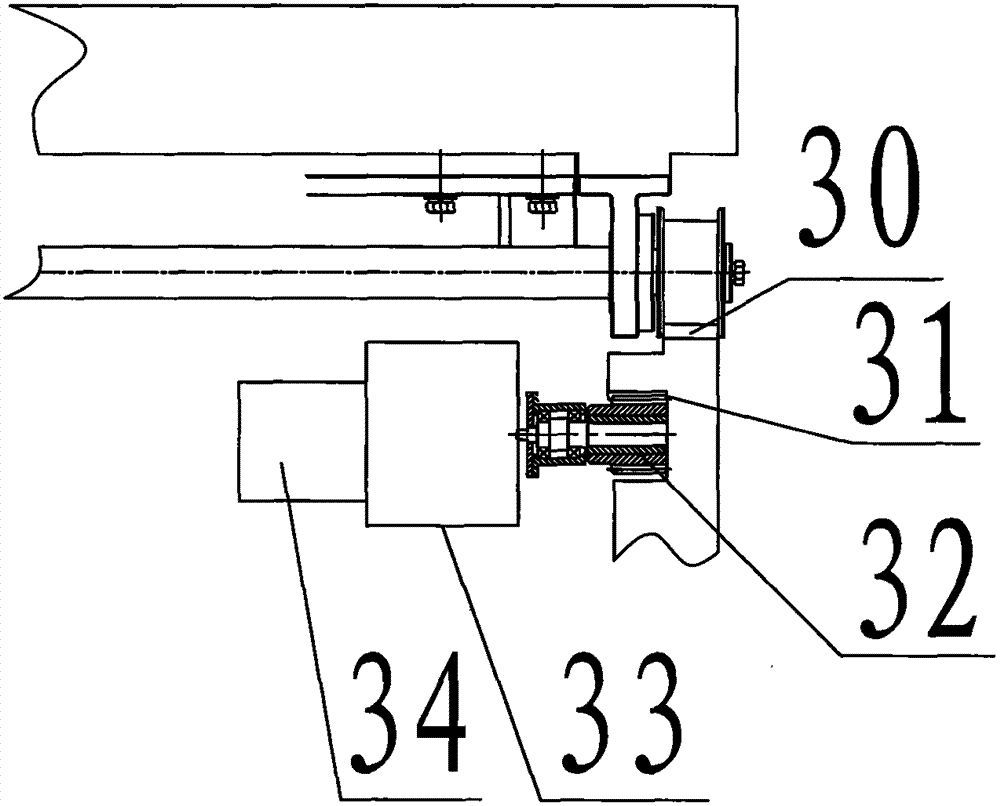

[0031] The invention includes: a track 30, an idler 19, a computer measurement and control system, and an idler transmission device, the track 30 is installed with an automatic detection vehicle 1, a flaw detection tank 20 is installed under the track 30, and an idler 19 is installed at the bottom of the flaw detection tank 20; Connected with the idler transmission device, the traveling reducer 33 is connected with the driving gear 32, the driving gear 32 meshes with the rack 31 on the side of the track 30, and the automatic detection vehicle 1 straddles the track.

[0032] The automatic detection vehicle 1 of the present invention includes: a motor, a detection host, and a moving frame 21. A motor is fixedly installed at the lower part of the automatic detection vehicle 1, a gear is installed on the motor head, and the gear is meshed with the rack. The movable frame 21 can move vertically below the automatic inspection vehicle 1 , and a probe frame is mounted on the movable fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com