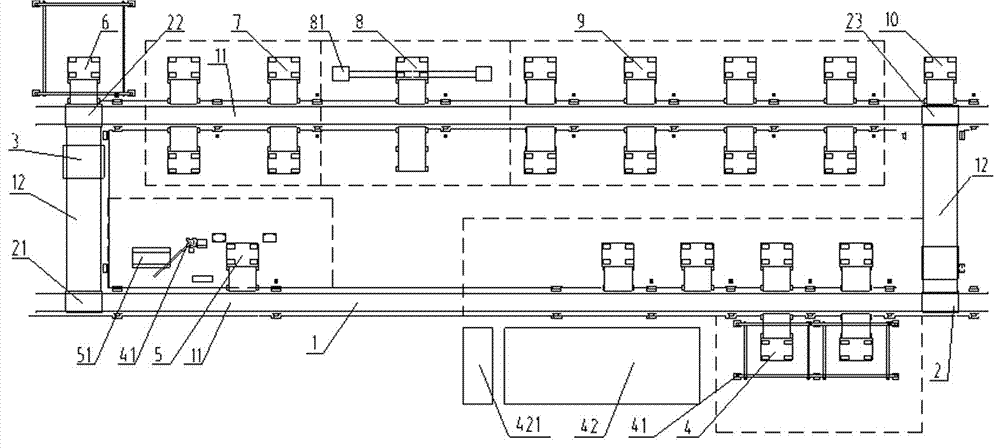

General assembly line for motor assembly

A technology of final assembly line and assembly table, applied in the direction of electromechanical devices, manufacturing of motor generators, electrical components, etc., can solve the problems of prone to collision, difficult to control the quality of motor assembly, low production efficiency, etc. Small bumps and hidden dangers and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with the accompanying drawings.

[0010] like figure 1 As shown, the present invention includes a track 1, on which a flat car 2 is provided; both sides of the track 1 are sequentially provided with a plurality of stator outlet box installation positions 4, and at least one collector ring heat-fitting platform along the track direction Position 5, at least one rotor blower assembly position 6, multiple small shaft mounting positions 7, multiple cooler assembly positions 8 and multiple motor storage stack positions 9; the stator outlet box installation position 4 A pneumatic suspension crane 41 is provided above, a stator-rotor assembly machine 42 is provided next to the stator outlet box installation station 4, and a rotor preparation stand 421 is provided next to the stator-rotor assembly machine 42; A collector ring heating oven 51 and a pneumatic suspension crane 41 are arranged next to it; a track...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com