Lining material for rehabilitating existing pipe and method for rehabilitating existing pipe using same

A bushing and base material technology, applied in the field of bushing materials for repairing installed pipes and repairing installed pipes using the material, can solve the problem of excessive increase in viscosity of furan resin composition, increase in viscosity of furan resin, difficulty in ensuring Impregnation ability and other issues, to achieve effective and convenient thin thickness, high strength, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0117] Only a furan resin component (a cocondensate of furfuryl alcohol and formaldehyde, a viscosity of 2700 mPa·s, and a moisture content of 7.4% by weight) was used as the furan-based resin.

[0118] Furthermore, after adding 3 parts by weight of a curing agent (65% p-toluenesulfonic acid aqueous solution) to 100 parts by weight of the furan-based resin, they were stirred at 1000 rpm for 10 minutes using a "Homodisper", Thus, a curable furan resin composition was prepared.

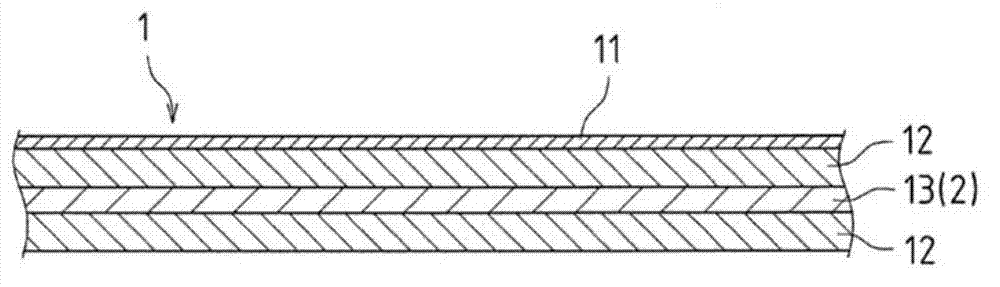

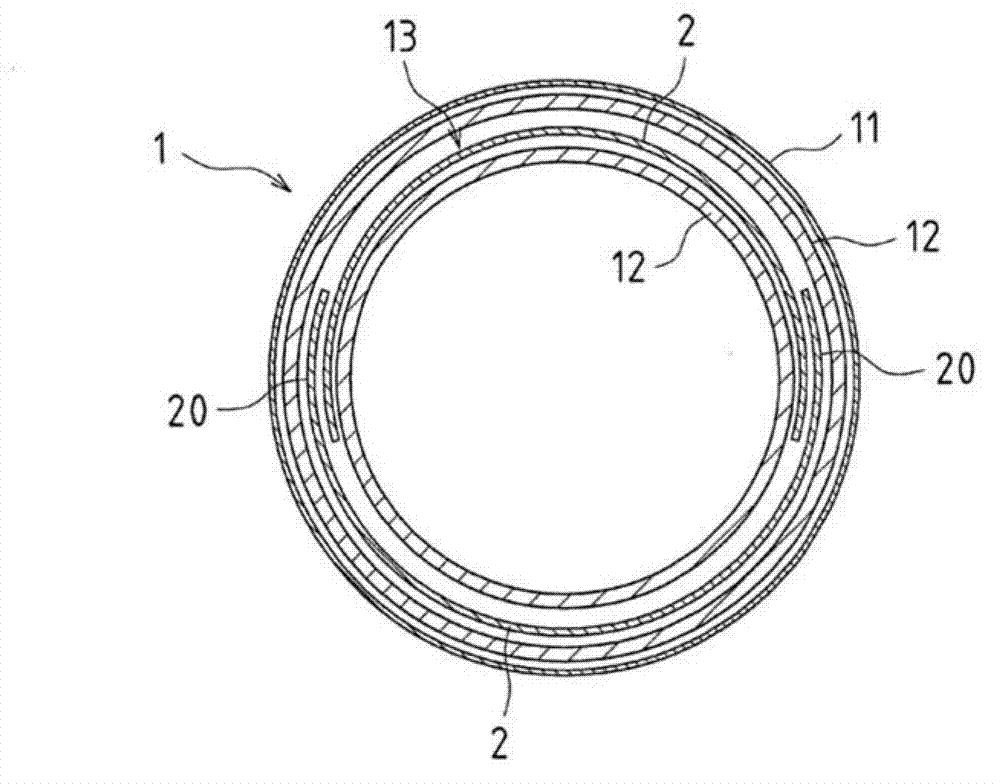

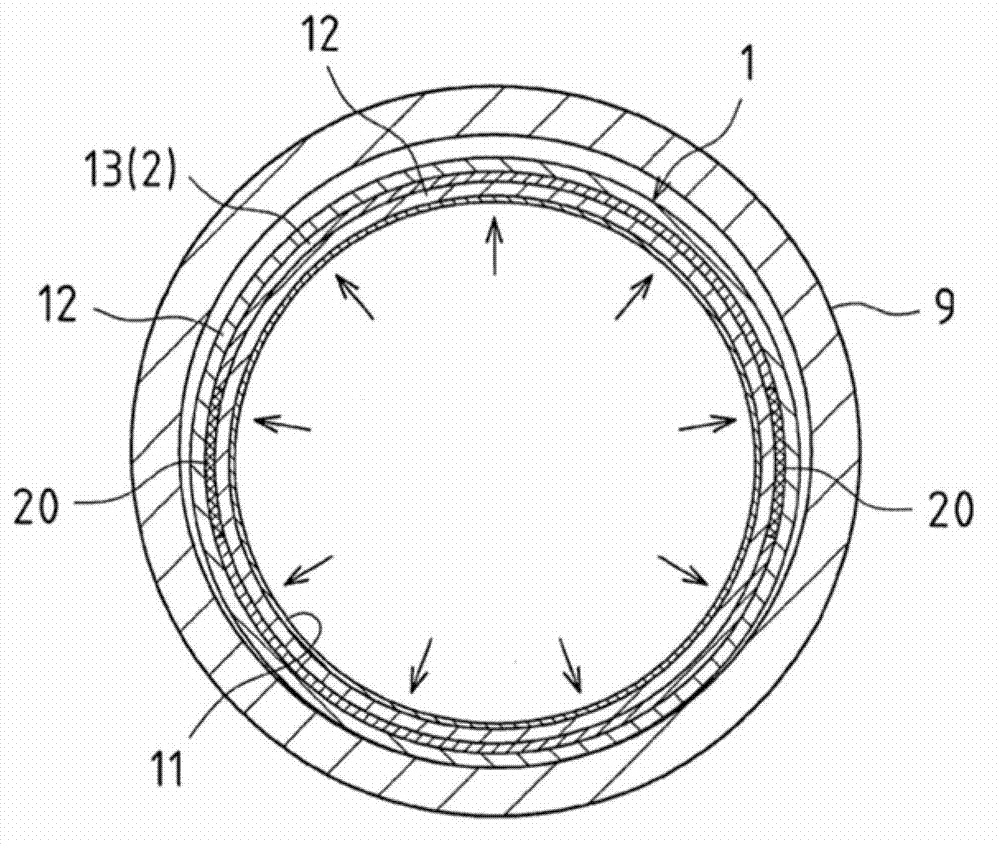

[0119] Inject 7500 g / m inside the base material of the tubular liner consisting of a tubular laminate covered on the outer surface with a water-impermeable layer 2 The curable furan resin composition, wherein the tubular laminate is made of resin non-woven fabric (polyester non-woven fabric, porosity 85%, and 460g / m 2 ) and resin non-woven fabric (polyester non-woven fabric, porosity 85%, and 600g / m 2 ) was made; then the inside of the base material was degassed by decompressing the inside of the base...

Embodiment 2

[0122] After adding 40 parts by weight of furfural to 100 parts by weight of the furan resin component (cocondensate of furfuryl alcohol and formaldehyde, with a viscosity of 2700 mPa·s and a moisture content of 7.4% by weight), it was dispersed in the Stir at 1000 rpm for 5 minutes to prepare a furan-based resin. After that, using the furan-based resin, a repaired underground pipe was obtained by a method similar to that in Example 1. The evaluation results are shown in Table 1.

Embodiment 3

[0124] After adding 50 parts by weight of furfuryl alcohol to 100 parts by weight of the furan resin component (cocondensate of furfuryl alcohol and formaldehyde, with a viscosity of 2700 mPa·s and a moisture content of 7.4% by weight), it was dispersed in the Stir at 1000 rpm for 5 minutes to prepare a furan-based resin. After that, using the furan-based resin, a repaired underground pipe was obtained by a method similar to that in Example 1. The evaluation results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com