A kind of low-strength and low-permeability concrete and preparation method thereof

A technology of concrete and low water permeability, applied in the field of building materials, can solve the problems of good water permeability and large internal porosity, and achieve the effects of high core-pulling continuity, low water permeability, and less sediment at the bottom of the pile

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The present invention also provides a method for preparing low-strength and low-permeability concrete, comprising the following steps:

[0041] S1: Try mixing 40-60 liters of concrete, and determine the dosage of each component according to the mass ratio of the components of each cubic concrete mixture;

[0042] S2: In order to fully and evenly mix the components together during stirring, before stirring, beat the large pieces of clay into lumps with a particle size of less than 50mm, take out 15-20% of the water to wet the inner wall of the mixer, and weigh it. Add the good clay and sand to the mixer and mix for 30-40s; the inner wall of the mixer should be wetted with water first, so that it is not easy for the mixture to stick to the inner wall when adding the mixture later, first pour the clay and sand into the mixer and stir Evenly, then add cement and fly ash, then add 50-60% water, and stir for 40-60s; at this time, no water-reducing agent has been added, and th...

Embodiment 1

[0047] The present embodiment provides a kind of low-strength and low-permeability concrete, and its preparation method is as follows:

[0048] S1: Trial mix 60 liters of concrete, weigh each component cement: fly ash: clay: sand: water: water reducing agent;

[0049] S2: Beat the large pieces of clay into lumps with a particle size of less than 50mm, take out 15-20% water to wet the inner wall of the mixer, add the weighed clay and sand to the mixer, and stir for 30-40s; add cement and pulverized coal Ash, then add 50-60% water, stir for 40-60s; then add water reducer and remaining water, stir for 120-150s;

[0050] S3: Take out part of the mixture and put it into the slump bucket to measure the slump; if the slump is between 100 and 150mm, take out the mixture for mold maintenance, and cure it for 28 days under standard curing conditions and measure the mold The compressive strength of the test block is qualified.

[0051] According to the weight ratio of various mixture m...

Embodiment 2

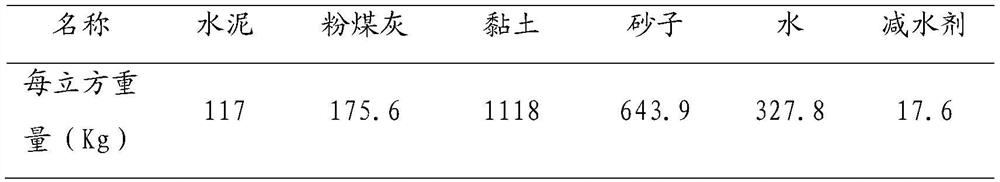

[0076] The present embodiment provides a kind of low-strength and low-permeability concrete, and the weight of each cubic meter of concrete components is shown in Table 5:

[0077] Table 5. Concrete mix ratios used in Example 2

[0078]

[0079] Other operations are the same as in Example 1.

[0080] Among them, the cement is 32.5 slag Portland cement; the fly ash is Class F first-class fly ash; the sand is medium sand; ; Clay is clay with a plasticity index > 17; tap water is used for water.

[0081] In this implementation, the amount of cement and sand is reduced, and the amount of fly ash and clay is increased. By adjusting the dosage of each mixture, the concrete prepared by the mixing ratio in this example is applied to the water-stop pile. Through the drilling core test of the water-stop pile, it is found that the core-taking effect is good, the core-taking continuity is good, and the broken core is not broken. There are few cores and sediments; and when the casing d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com