Nutritious bone for pet dog

A technology for nourishing bones and pet dogs, applied in applications, animal feed, animal feed, etc., can solve problems such as indigestion of pet dogs, and achieve the effects of moderate hardness, increased appetite, and beautiful appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

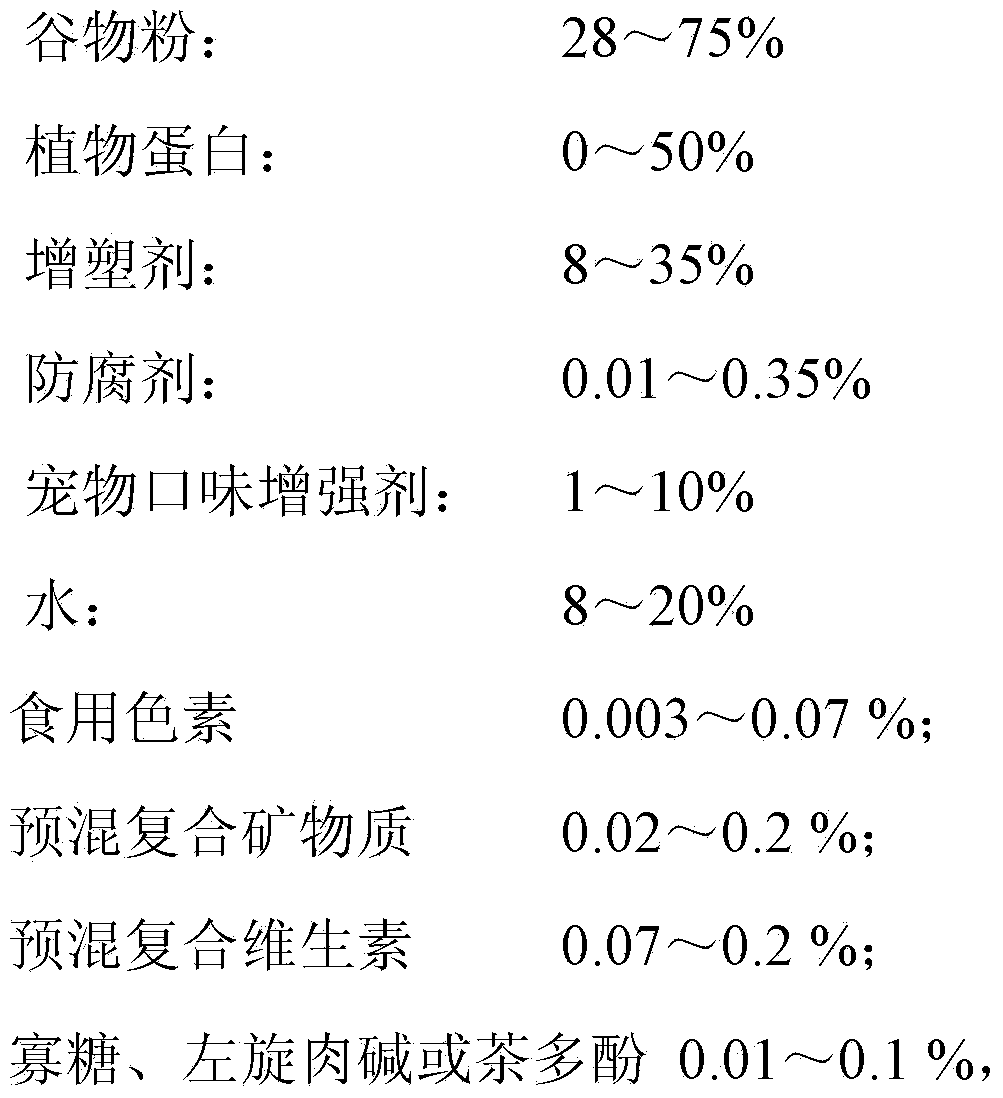

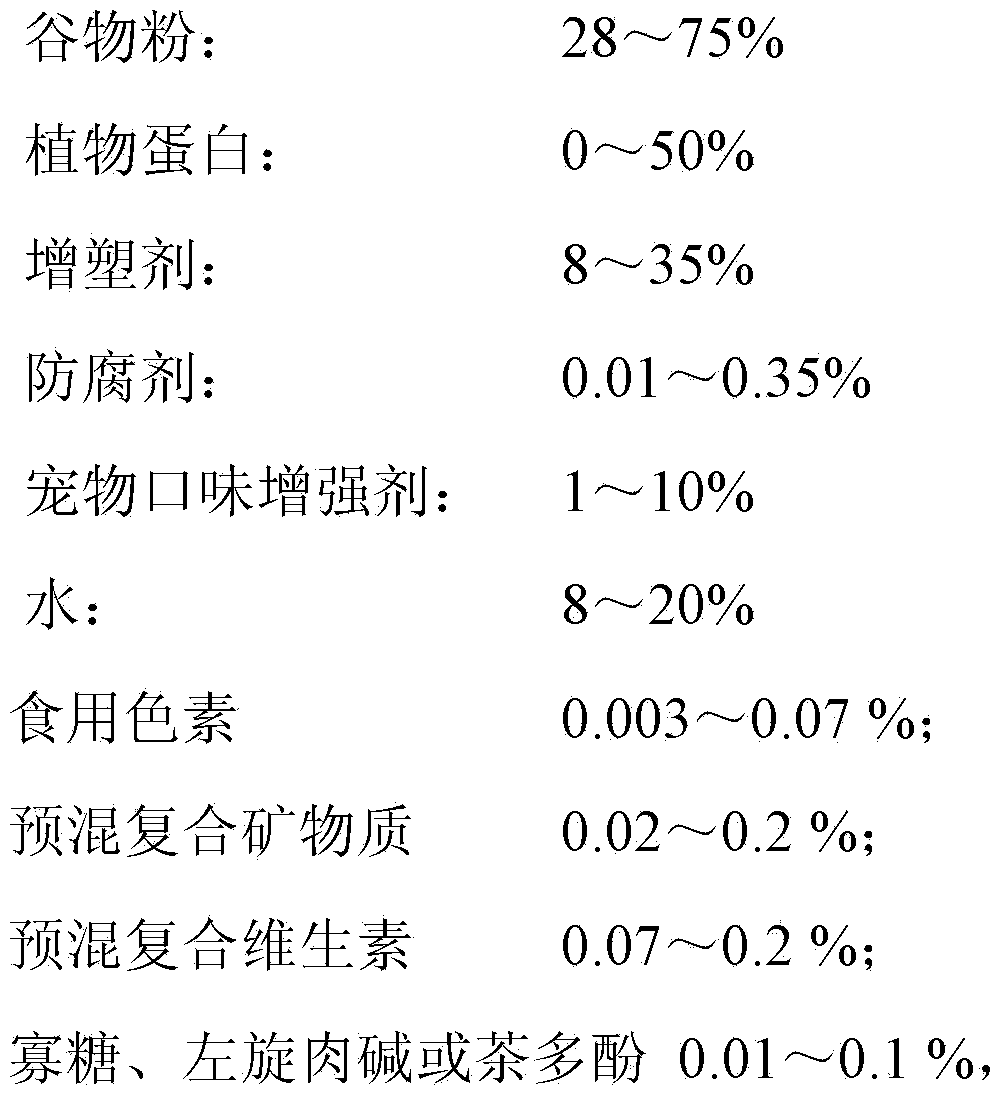

Method used

Image

Examples

Embodiment 1

[0043] 1) Preparation of raw materials: Accurately weigh the two raw materials according to formulas 1 and 2 and stir them evenly;

[0044] 2) Pelletization: Put the two raw materials weighed into a screw extruder respectively, the temperature at the feed end is 81°C, the temperature at the die end is 135°C, the molding section of the extrusion die is circular, and the Rotate the cutter to obtain white milk-flavored and green mint-flavored cylinders with a length of 4mm and a diameter of 3mm, respectively, and then cool to room temperature by air cooling;

[0045] 3) Two-color extrusion: put the above two cylinders into different screw extruders respectively, the temperature at the feed end is 52°C, and the temperature at the die end is 92°C, and co-extrude into two-color, 35mm wide and 1.5mm thick through a two-color die mm strip-shaped semi-finished products, and then cut into small sections with a length of 240mm, and each small section is composed of two material strips wi...

Embodiment 2

[0050] 1) Preparation of raw materials: Accurately weigh the two raw materials according to formulas 4 and 5 and stir them evenly;

[0051] 2) Granulation: Put the two raw materials into a screw extruder respectively, the temperature at the feed end is 85°C, and the temperature at the die end is 120°C. , to obtain red barbecue flavor and brown beef flavor cylinders with a length of 5mm and a diameter of 3mm, respectively, and then cool to room temperature by air cooling;

[0052] 3) Two-color extrusion: Put the above two cylinders into different screw extruders respectively, the temperature at the feed end is 60°C, the temperature at the die end is 90°C, and the width is 38mm and the thickness is 2mm by co-extrusion through the two-color die Two-color strip-shaped semi-finished products, and then cut into small sections with a length of 260mm;

[0053] 4) Manual molding: make the above-mentioned small sections into bowknot shapes;

[0054] 5) Drying: Dry the bowtie-shaped ve...

Embodiment 3

[0057] 1) Preparation of raw materials: Accurately weigh the two raw materials according to formulas 1 and 3 and stir them evenly;

[0058] 2) Pelletization: Put the two raw materials into a screw extruder respectively, the temperature at the feed end is 80°C, the temperature at the die end is 125°C, the molding section of the extrusion die is circular, and the rotary cutter passing through the section of the die end , to obtain white milk-flavored and yellow chicken-flavored cylinders with a length of 6 mm and a diameter of 3 mm, respectively, and then cool to room temperature by air cooling;

[0059] 3) Two-color extrusion: put the above two cylinders into different screw extruders respectively, the temperature at the feed end is 65°C, the temperature at the die end is 95°C, and the width of the upper and lower layers is 30mm by co-extrusion through the two-color die. Two-color strip-shaped semi-finished product with a thickness of 1.5mm, and then cut into small sections wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com