Water chestnut peeling machine

A peeling machine and horseshoe technology, applied in the peeling of vegetables or fruits, food science, application, etc., can solve the problems of difficult selection of manufacturing process and materials, difficult promotion, and too deep peeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

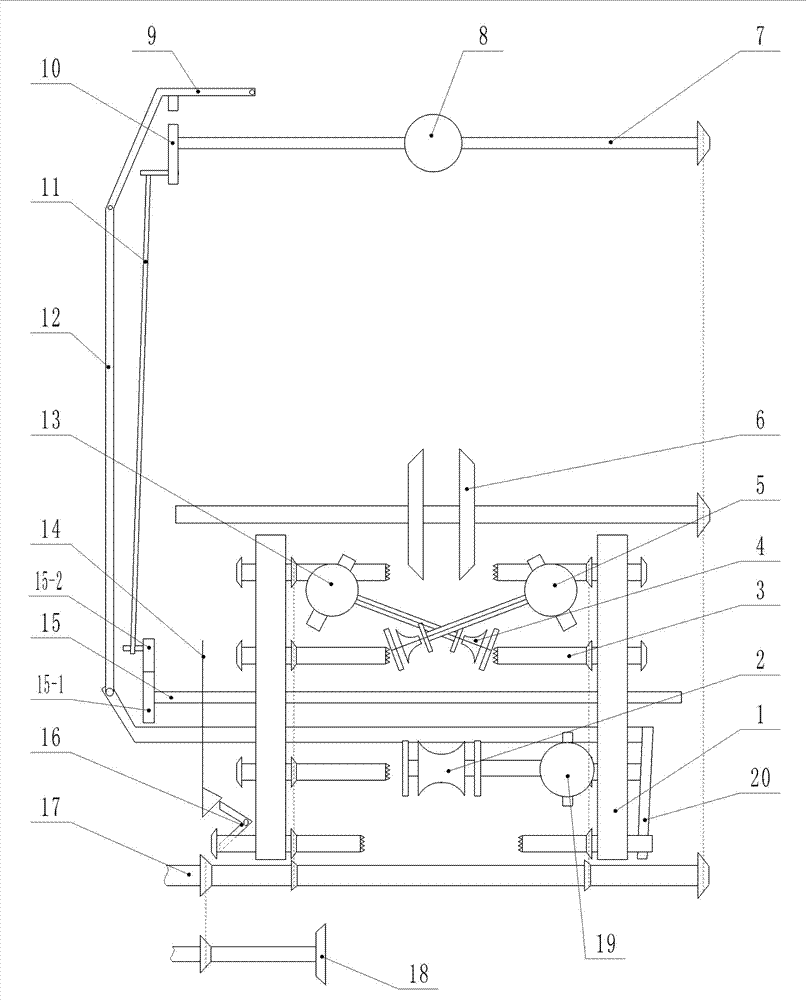

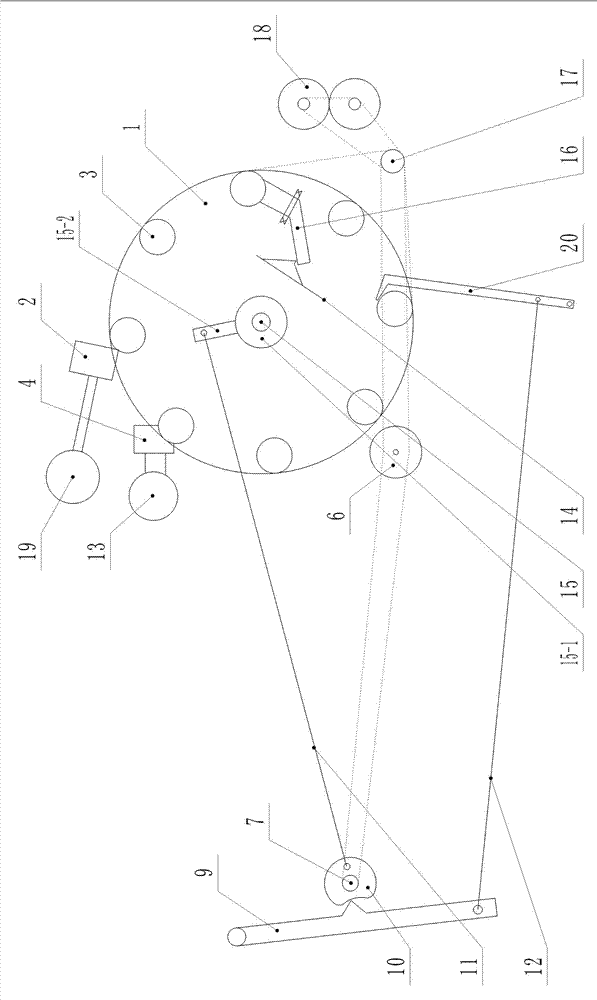

[0019] refer to figure 1 figure 2 , a horseshoe peeling machine, comprising a frame, a turntable 1, a main shaft cam 10, a peeler, a pedicle cutter 6, a seedling cutter 18 and a power mechanism, wherein there are two turntables 1, and the faces of the turntable 1 are opposite to each other. Correspondingly vertically arranged on the frame, 2-50 groups of synchronous top cores 3 are arranged on the turntable 1, eight groups in this example, each group of synchronous top cores 3 is two, and the two synchronous top cores 3 are respectively arranged on two On the turntable 1, the clamping ends of the synchronous top cores 3 are opposite, and the synchronous top cores 3 are connected to the power mechanism. Each group of synchronous top cores 3 is equipped with a rocker I 16, and the rocker I 16 is rotated by the turntable 1 and fixed on the frame The bump I 14 cooperates to push the synchronous top core 3 to the outside of the turntable 1, so that the horseshoe is placed on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com