Treatment method for chromium-containing waste residue in steel industry

A technology of iron and steel industry and treatment method, applied in the field of waste slag treatment process of iron and steel industry, can solve problems such as secondary pollution and rebound, and achieve the effect of reducing chromium content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

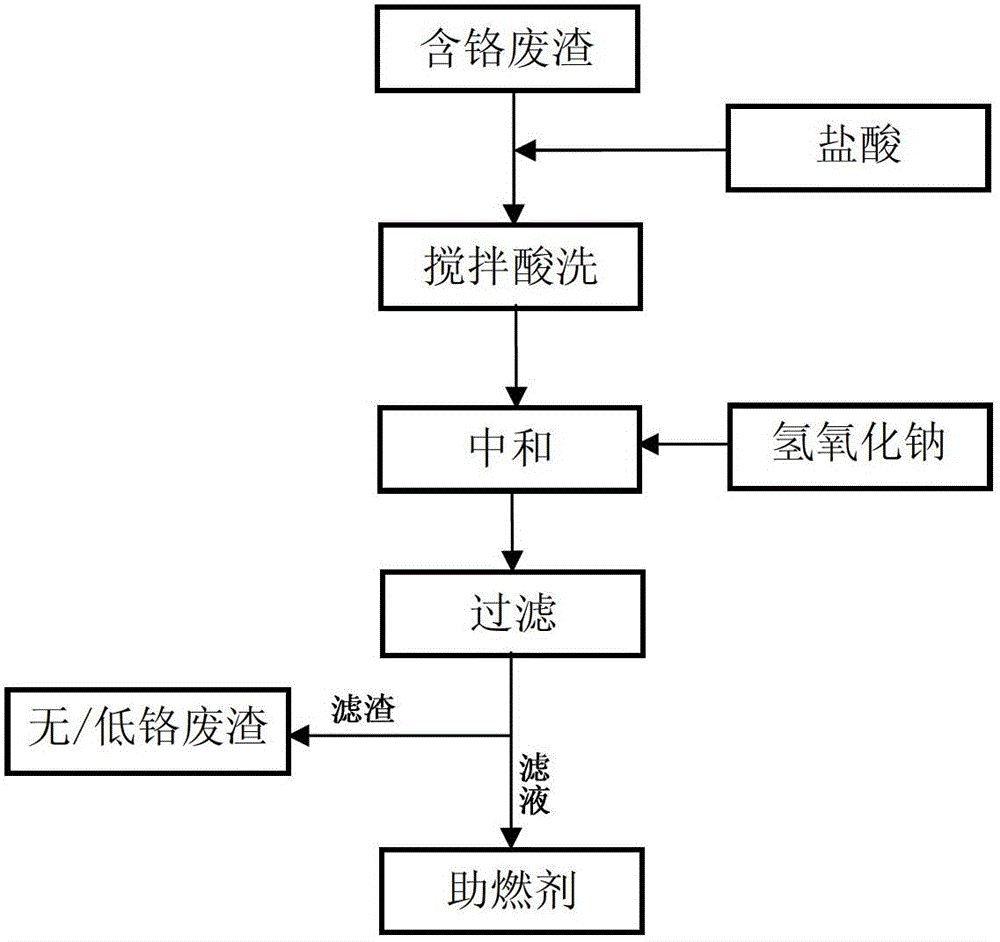

Embodiment 1

[0025] Raw materials: chromium-containing waste slag from cold rolling process wastewater treatment in the iron and steel industry, its Cr 2 o 3 The content is 5.3% by mass.

[0026] (1) Put chromium-containing waste residue (hereinafter referred to as chromium residue) into the stirring tank, and then add hydrochloric acid solution (water:concentrated hydrochloric acid volume ratio is 1:1), the solid-liquid mass ratio of chromium residue to hydrochloric acid solution is 1:1 , to make a mixture.

[0027] (2) After the mixture is fully stirred for 10 minutes, add NaOH solution (concentration: 15-30%) to adjust the pH value to 5-6, and then filter to obtain the filtrate and filter residue. The filtrate is the combustion enhancer 1. The filter residue was tested by leaching, the total chromium: 16.8mg / L, hexavalent chromium <2.8mg / L.

Embodiment 2

[0029] Raw materials: chromium-containing waste slag from cold rolling process wastewater treatment in the iron and steel industry, its Cr 2 o 3 The content is 6.6%.

[0030] (1) Put chromium-containing waste slag (hereinafter referred to as chromium slag) into the stirring tank, and then add hydrochloric acid solution (water: concentrated hydrochloric acid is 1:1), the solid-liquid mass ratio of chromium slag and hydrochloric acid is 1: 4, and the Mixture.

[0031] (2) After the mixture is fully stirred for 30 minutes, add NaOH solution (concentration: 15-30%) to adjust the pH value to 5-6, and then filter to obtain the filtrate and filter residue. The filter residue was tested by leaching, the total chromium: 9.2mg / L, hexavalent chromium <2.1mg / L.

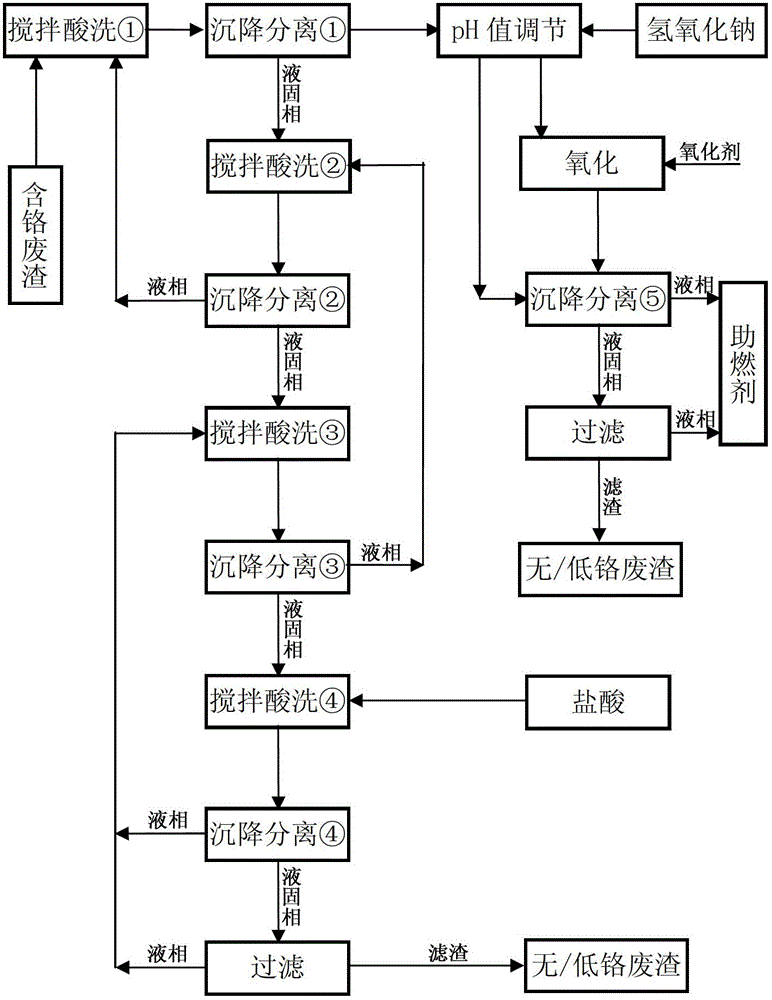

Embodiment 3

[0033] Raw materials: chromium-containing waste slag from cold rolling process wastewater treatment in the iron and steel industry, its Cr 2 o 3 The content is 26.36%.

[0034] (1) Put chromium-containing waste slag into a stirred tank for four-stage reverse pickling (the number of pickling stages can be reasonably designed according to the chromium content in chromium-containing waste slag), specifically, the chromium-containing waste slag is added to the 2-stage pickling The supernatant (that is, the pickling solution) is subjected to a first-stage stirring pickling, and then the supernatant and the liquid-solid phase are separated by settling, and the supernatant after the first-stage pickling is used as a mixed solution to enter the next process; the first-stage pickling The final liquid-solid phase is added to the supernatant after the 3-stage pickling (that is, the pickling solution) for 2-stage stirring pickling, and then the supernatant and the liquid-solid phase are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com