Bottle body conveying device

A technology for conveying devices and bottles, which is applied in the direction of conveyor control devices, conveyor objects, transportation and packaging, etc., can solve problems such as low operating efficiency, high pollution, and restrictions on the production efficiency and production stability of pharmaceutical companies, and achieve outstanding results. Substantial features, the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

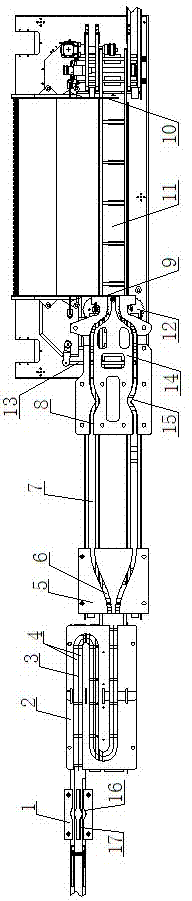

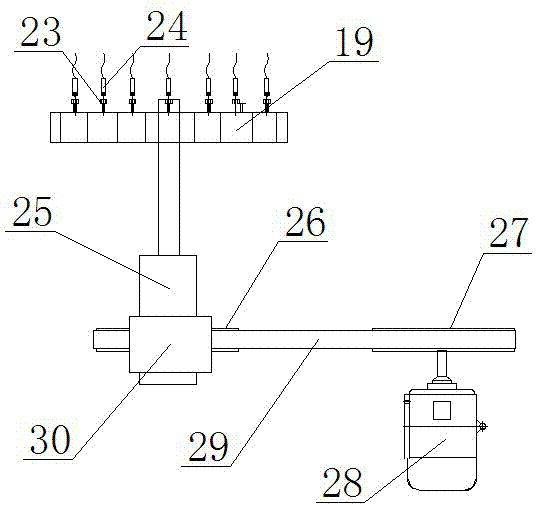

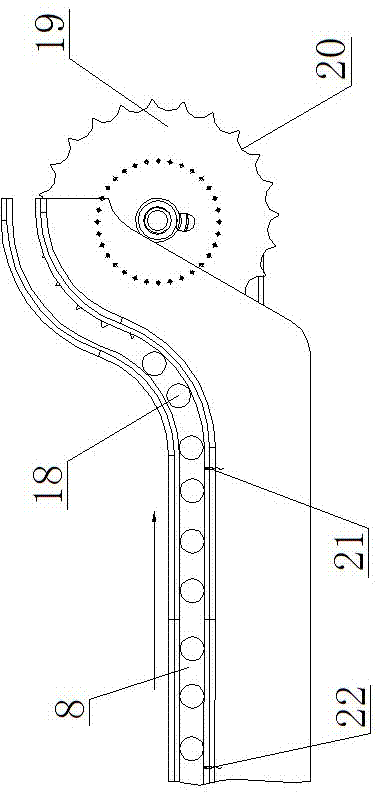

[0019] In order to clearly illustrate the technical characteristics of this solution, the following will describe this solution through specific implementation modes and in conjunction with the accompanying drawings.

[0020] A bottle conveying device, such as figure 1 As shown, it includes a conveyor belt 7 and a distribution mold 5, a feed mold 14, a star wheel feed device 12 and a transfer station 11 arranged in sequence along the running direction of the conveyor belt 7, and the distribution mold 5 runs through There are at least two conveying passages 6, and at least two conveying passages 8 run through the feed mold 14, preferably two conveying passages, the number of conveying belts 7 and star wheel feeding devices 12 is the same as the number of conveying passages 6 and 8 Equally, the star wheel feeding device 12 cooperates with each conveying channel 8 on the feeding mold 14, and the inlet end of the transfer station 11 and the end opposite to the inlet end are respec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com