Pretreatment anaerobic biochemical regulation device

A conditioning device and pretreatment technology, applied in anaerobic digestion treatment, waste fuel, etc., can solve the problems of idle waste, large impact of the treatment system, sludge accumulation in the adjustment tank, etc., so as to reduce the hydraulic retention time and reduce the impact. The effect of load and prolonging the cleaning cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

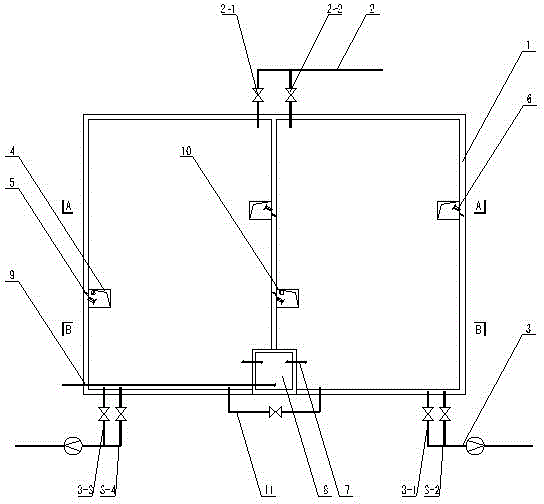

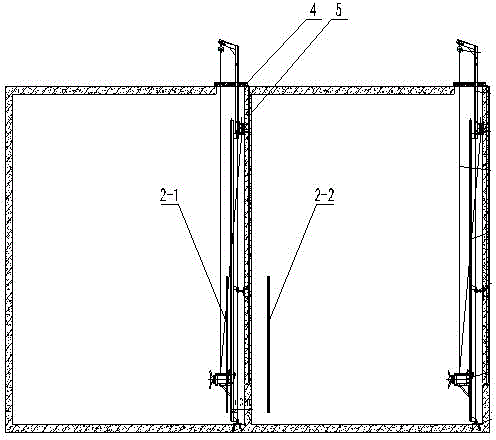

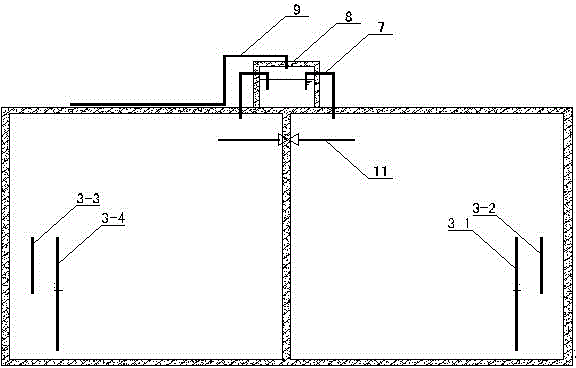

[0030] Such as figure 1 Shown is the structural schematic diagram of the pretreatment anaerobic biochemical regulator of the present invention; figure 2 Shown as figure 1 Sectional view of A-A; such as image 3 Shown as figure 1 Sectional view of B-B. The pretreatment anaerobic biochemical regulating device of the present invention includes a regulating tank 1, a water inlet pipe 2 and a water outlet pipe 3 connected to the regulating tank 1, and the regulating tank 1 is provided with an inspection hole and a liquid level alarm device. The regulating tank 1 includes two parallel A regulating pool body I and a regulating pool body II are set, a connecting pipe 11 is arranged between the regulating pool body I and the regulating pool body II, and the connecting pipe 11 is provided for controlling the series operation of the two pool bodies No less than two submersible agitators 6 are provided in the regulating tank body I and the regulating tank body II, respectively, and the ...

Embodiment 2

[0040] Such as Figure 4 Shown is a schematic diagram of the second embodiment of the anaerobic sludge reactor of the present invention;

[0041] The difference between this embodiment and the first embodiment is that the biogas collection device 8 includes a biogas collection water-sealed tank and a biogas discharge pipe 9. The regulating tank body I and the regulating tank body II are provided with inclined tops The said biogas collection water sealing tank is set at the height of the inclined top and the bottom is directly connected with the inside of the regulating tank body I and the regulating tank body II. The biogas discharge pipe 9 is provided with a check valve and a fire retarding valve. Embodiment The biogas collection device 8 has a simple structure, convenient construction, and fast collection of biogas.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com