Resolution process of racemic amino pentanamide

A technology of racemic aminovaleramide and aminovaleramide, which is applied in the field of splitting technology of racemic aminovaleramide, can solve the problems of increasing waste discharge, low splitting yield, etc., and achieves the effect of improving splitting yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0006] The present invention will be further described below in conjunction with specific examples.

[0007] 1. Embodiment

[0008] 1. Mix 105g of methanol and 45g of ethyl acetate to prepare a mixed solvent (the mass ratio of methanol and ethyl acetate should be kept at 1:2~2.5).

[0009] 2. Dissolve 20g of L-tartaric acid in 150g of the above-mentioned mixed solvent (wherein, the mass ratio of L-tartaric acid methanol to the above-mentioned mixed solvent should be kept at 1:7.5-8).

[0010] 3. Cool down to below 10°C, slowly add 40g of racemic aminovaleramide (the mass ratio of racemic aminovaleramide to the above L-tartaric acid should be kept at 2-2.5:1), and continue the reaction after adding After 2 to 2.5 hours, the discharge is filtered, and the filter cake is the resolution product L-aminovaleramide tartrate, and the weight of the wet product is 34.8g.

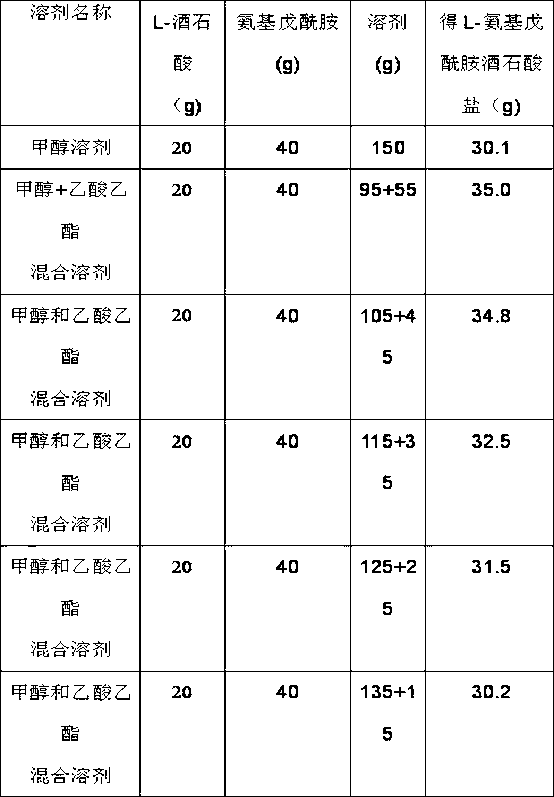

[0011] 2. Experimental data and results comparison

[0012]

[0013] As can be seen from the above table, whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com