Optical resolution method substituting oxyphosphonate acetate

An optical resolution, phosphine-based technology, applied in the optical resolution of racemates, splitting and substituting phosphinyl acetic acid to obtain its single enantiomer, can solve the problem of high solvent consumption and poor optical resolution method It can reduce the environmental pollution, increase the separation yield, and achieve the effect of simple and efficient recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

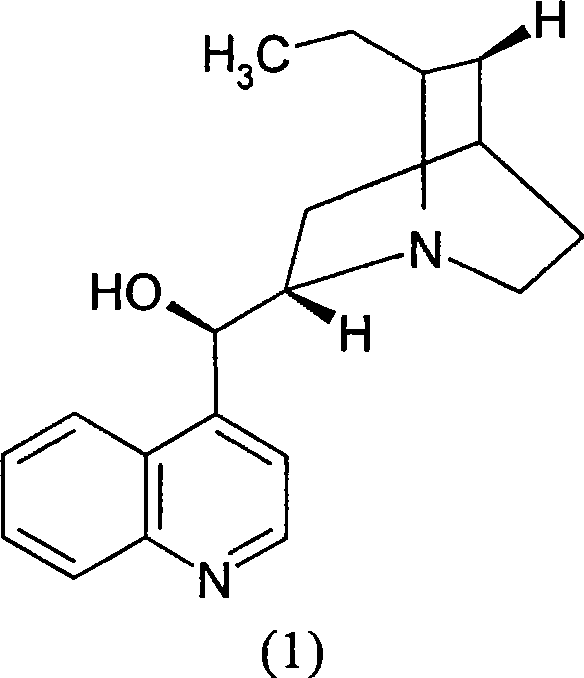

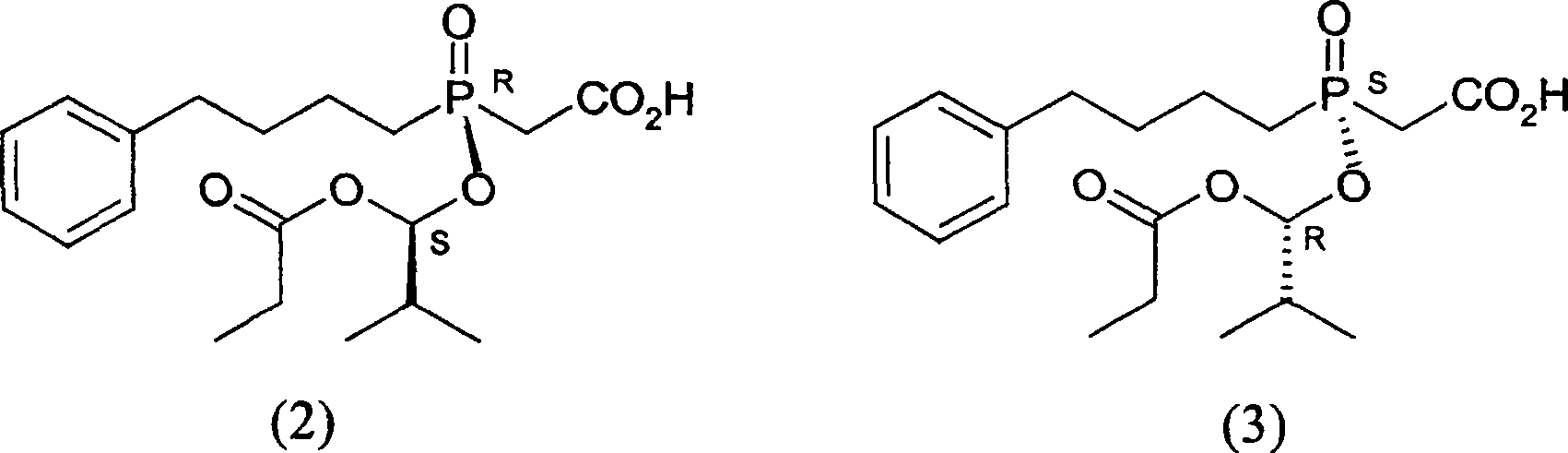

[0036] Mix and stir 10,11-dihydrocinchonidine (1) (3.56g, 12mmol) and ethyl acetate (30ml) to form a suspension, then add Base-1-(1-oxopropoxy)propoxy](4-phenylbutyl)phosphinyl]acetic acid (2) and [(S)-[(1R)-2-methyl-1- (1-oxopropoxy)propoxy](4-phenylbutyl)phosphinyl]racemate (7.68g, 20mmol) composed of acetic acid (3), heated to reflux with stirring until all solids Dissolved and filtered while hot. Add seed crystals to the filtrate, cool and crystallize. Suction filtration and vacuum drying gave the salt (4) generated from (2) and 10,11-dihydrocinchonidine (1) as a white solid (4.3g): melting point 125-126°C, [α] 20 D -31.7° (c=1, MeOH). A part of it was acidified and freed with dilute hydrochloric acid, and then extracted with dichloromethane to obtain oil (1): [α] 20 D +45.2° (c=1, EtOAc), the ee value determined by chiral stationary phase HPLC is 97.3%.

[0037] Get the above-mentioned salt (4) generated by (2) and 10,11-dihydrocinchonidine (1) and recrystallize on...

Embodiment 2

[0042] Mix and stir 10,11-dihydrocinchonidine (1) (7.11g, 24mmol) and ethyl acetate (68ml) to form a suspension, then add Base-1-(1-oxopropoxy)propoxy](4-phenylbutyl)phosphinyl]acetic acid (2) and [(S)-[(1R)-2-methyl-1- (1-Oxopropoxy)propoxy](4-phenylbutyl)phosphinyl]acetic acid (3) racemate (11.53g, 30mmol), stirred and heated until all solids were dissolved. Cool and crystallize. Suction filtration and vacuum drying gave the salt (4) formed from (2) and 10,11-dihydrocinchonidine (1) as a white solid (5.88g): melting point 122.1-125.4°C.

[0043] Get the above-mentioned salt (4) generated by (2) and 10,11-dihydrocinchonidine (1), and recrystallize once in ethyl acetate to obtain purified salt (4) produced by (2) and 10,11-dihydrocinchonidine (1). The salt (4) formed by hydrocinchonidine (1) is a white solid with a melting point of 123.4—126.5°C.

Embodiment 3

[0045] Mix and stir 10,11-dihydrocinchonidine (1) (2.96g, 10mmol) and ethyl acetate (60ml) to form a suspension, then add Base-1-(1-oxopropoxy)propoxy](4-phenylbutyl)phosphinyl]acetic acid (2) and [(S)-[(1R)-2-methyl-1- (1-Oxopropoxy)propoxy](4-phenylbutyl)phosphinyl]acetic acid (3) racemate (7.68g, 20mmol), stirred and heated until all solids were dissolved. Cool and crystallize. Suction filtration and vacuum drying gave the salt (4) generated by (2) and 10,11-dihydrocinchonidine (1) as a white solid (3.13g): melting point 124.9—126°C, [α] 20 D -29.6° (c=1, MeOH).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com