Built-in air bag type anti-collision device

A technology of anti-collision devices and airbags, applied in road safety devices, roads, roads, etc., can solve the problems of short service life, high investment cost of anti-collision facilities, poor anti-collision effect, etc., and achieve convenient construction, simple construction steps, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

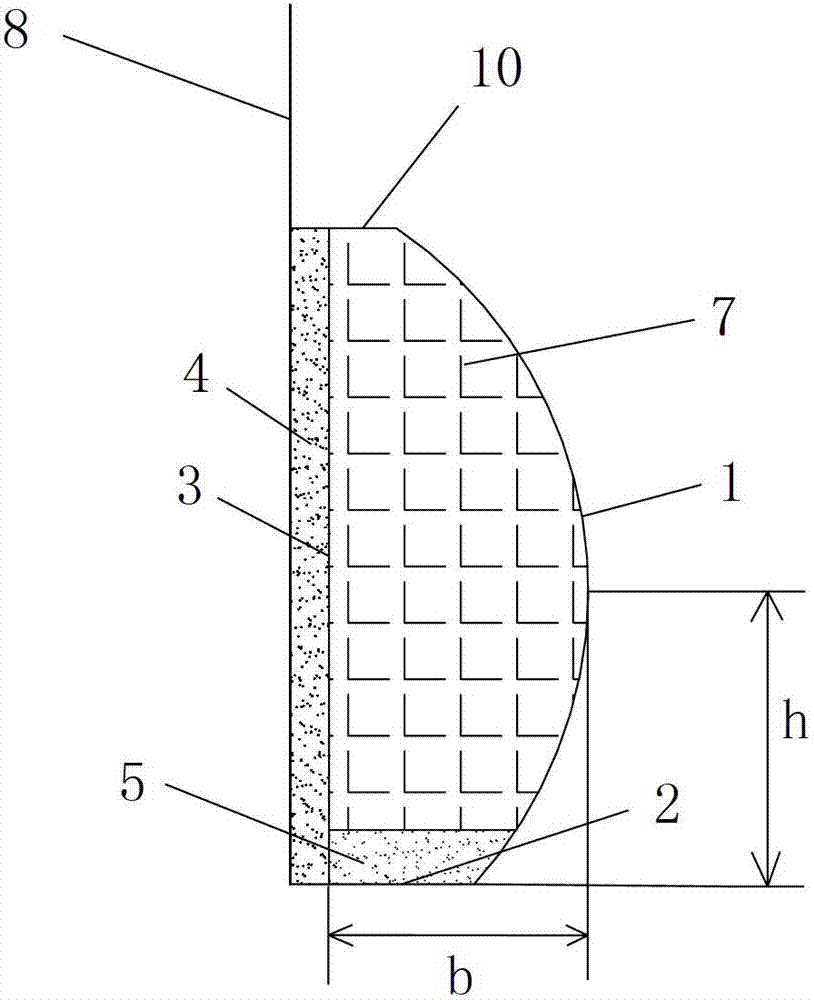

[0036] Such as figure 1 A built-in airbag-type anti-collision device shown includes an outer steel wall panel 1 and an inner steel wall panel 3 located inside the outer steel wall panel 1 , and a gap between the outer steel wall panel 1 and the inner steel wall panel 3 An anti-collision cavity is formed, the bottom of the anti-collision cavity is provided with a layer of counterweight cushion 5, and the anti-collision cavity on the top of the counterweight cushion 5 is densely filled with a plurality of rubber airbags 7, and the plurality of The rubber airbags 7 are arranged on the same plane. The lined steel wall plate 3 is located outside the device to be protected, and an energy-absorbing cushion 4 is arranged between the lined steel wall plate 3 and the device to be protected. The outer steel wall plate 1 and the inner steel wall plate 3 are arranged on the same plane, and the vertical heights of the two are the same. The outer steel wall plate 1 is an outwardly protrudin...

Embodiment 2

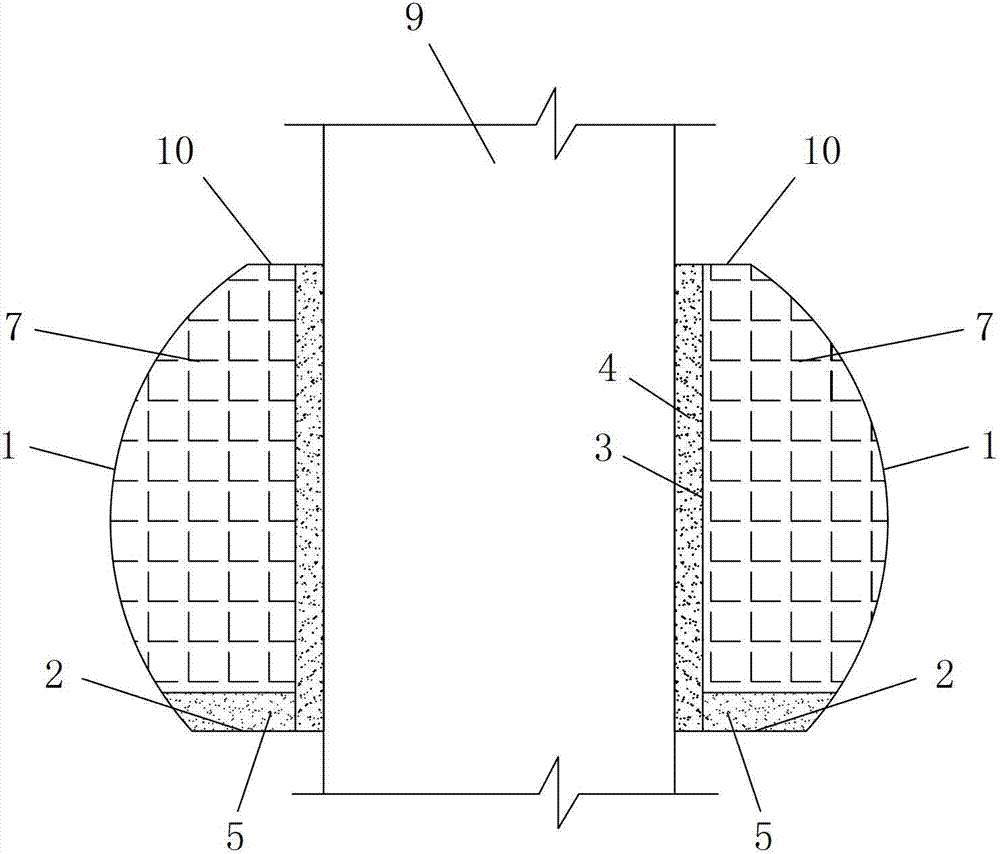

[0061] In this example, if figure 2 As shown, the difference from Example 1 is that: the protection device to be protected is an anti-collision column 9; the lined steel wall plate 3 arranged on the outside of the anti-collision column 9 is an annular steel plate 1 bent from a straight steel plate 2, The outer steel wall plate 1 located on the outer side of the first ring-shaped steel plate is the second ring-shaped steel plate bent by the second circular-arc-shaped steel plate. The cross-section of the second circular-arc-shaped steel plate is arc-shaped; The outer side of the anti-collision column 9, and the second ring-shaped steel plate is set on the outer side of the first ring-shaped steel plate; the plurality of rubber airbags arranged in the anti-collision cavity between the first ring-shaped steel plate and the second ring-shaped steel plate 7. Lay out along the circumferential direction. Between the first ring-shaped steel plate and the second ring-shaped steel pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com