Comprehensive building of urban water plant

An all-round, water plant technology, applied in the direction of industrial buildings, etc., can solve the problems of occupying a lot of land, inconvenience, and large investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

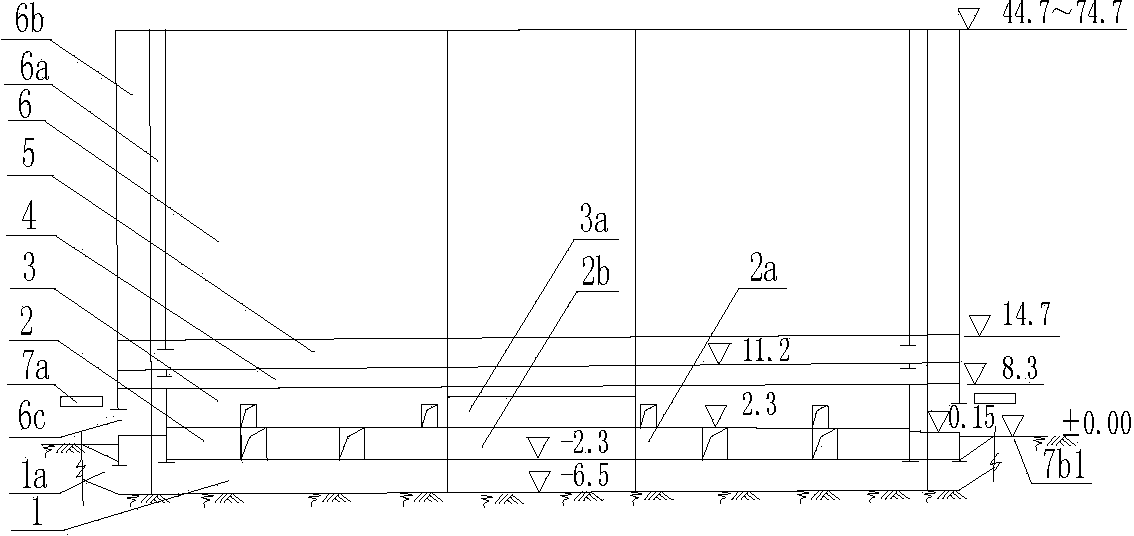

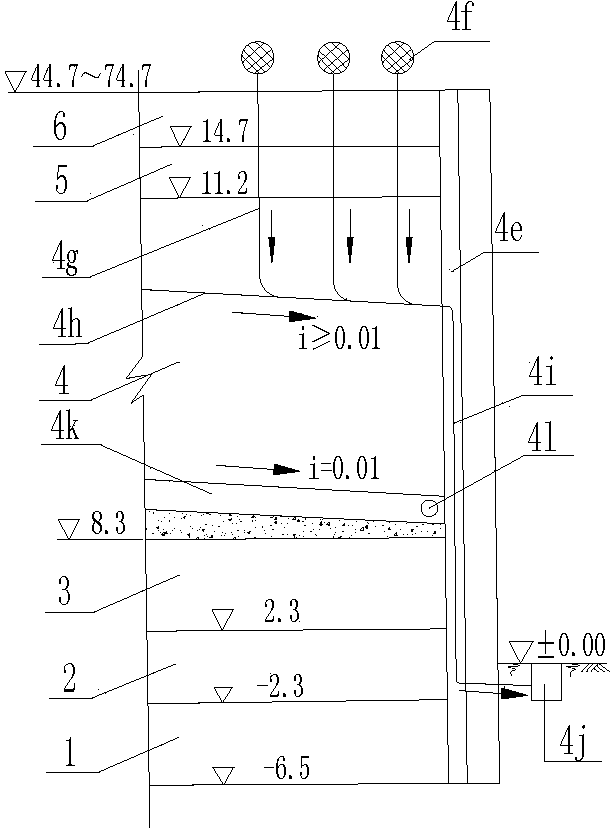

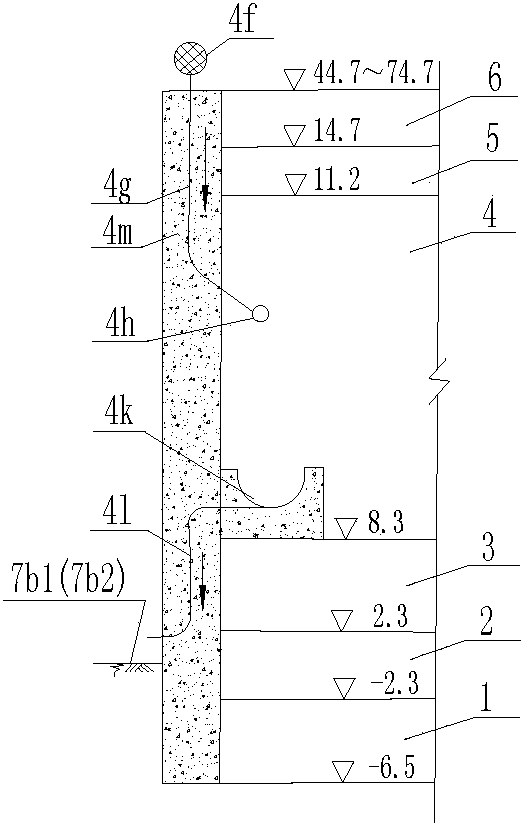

[0024] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0025] Such as Figure 1-13 As shown, the present invention includes an underground garage (1), a waterworks process layer (2), an operation layer (3), a pipeline isolation layer (4), a plant service layer (5), and high-rise residential buildings in the all-purpose building (7). Building (6), resident elevator (6a), resident ladder (6b), factory service staircase (5g), workshop staircase (3f) and the local overhead bridge of the factory road (7y) outside the all-purpose building (7) ( 7a) and the isolation wall (7m), there are resident elevators (6a) and resident steps (6b) at both ends of the omnipotent building (7), leading from the top floor to the underground garage (1) through the middle floors , there is a resident gate (6c) on the outer wall of the stairwell foyer at an elevation of +0.15m, outside the gate is the family...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com