Two-stage two-section separate-injection pipe column capable of back-flushing well and protected by insert seal sleeve and separate-injection method of two-stage two-section separate-injection pipe column

A technology of inserting sealing and backwashing wells, applied in casing, flushing wellbore, sealing/packing, etc., can solve the problems of high overhaul probability, small inner diameter of packer central pipe, high cost, and reduce overhaul probability , The effect of large flushing channel and high success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

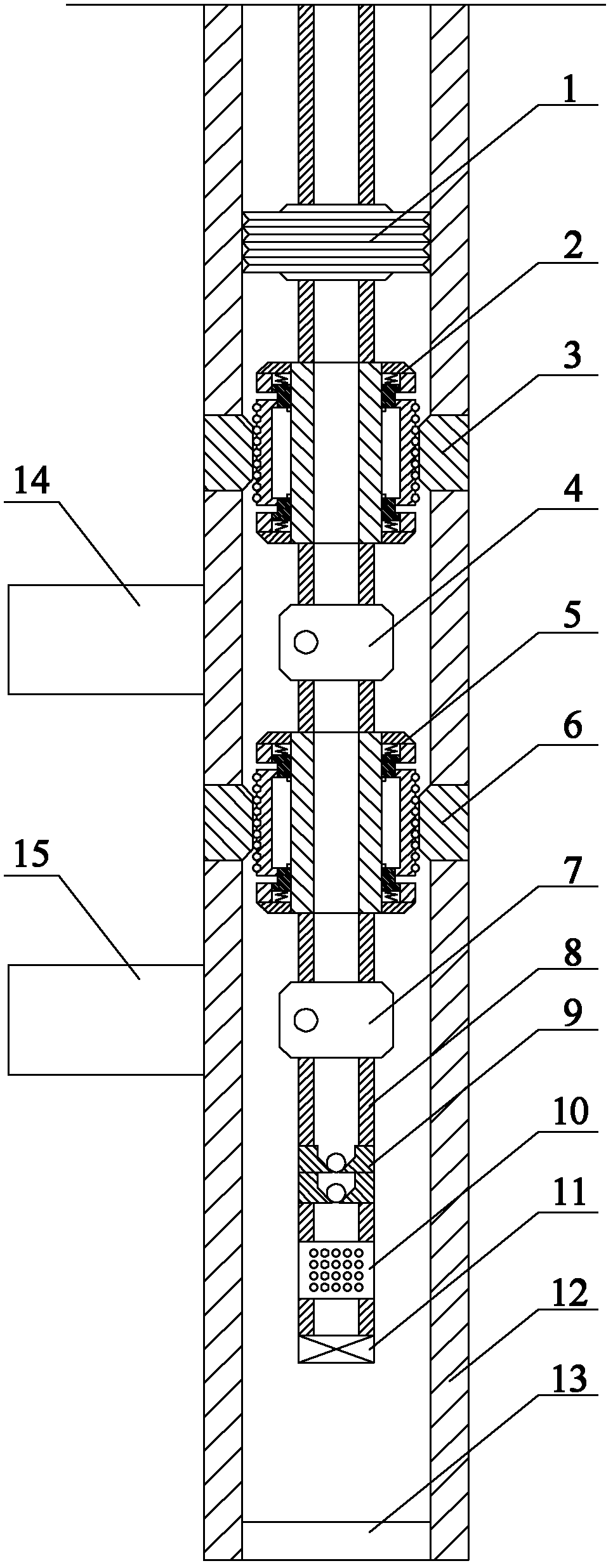

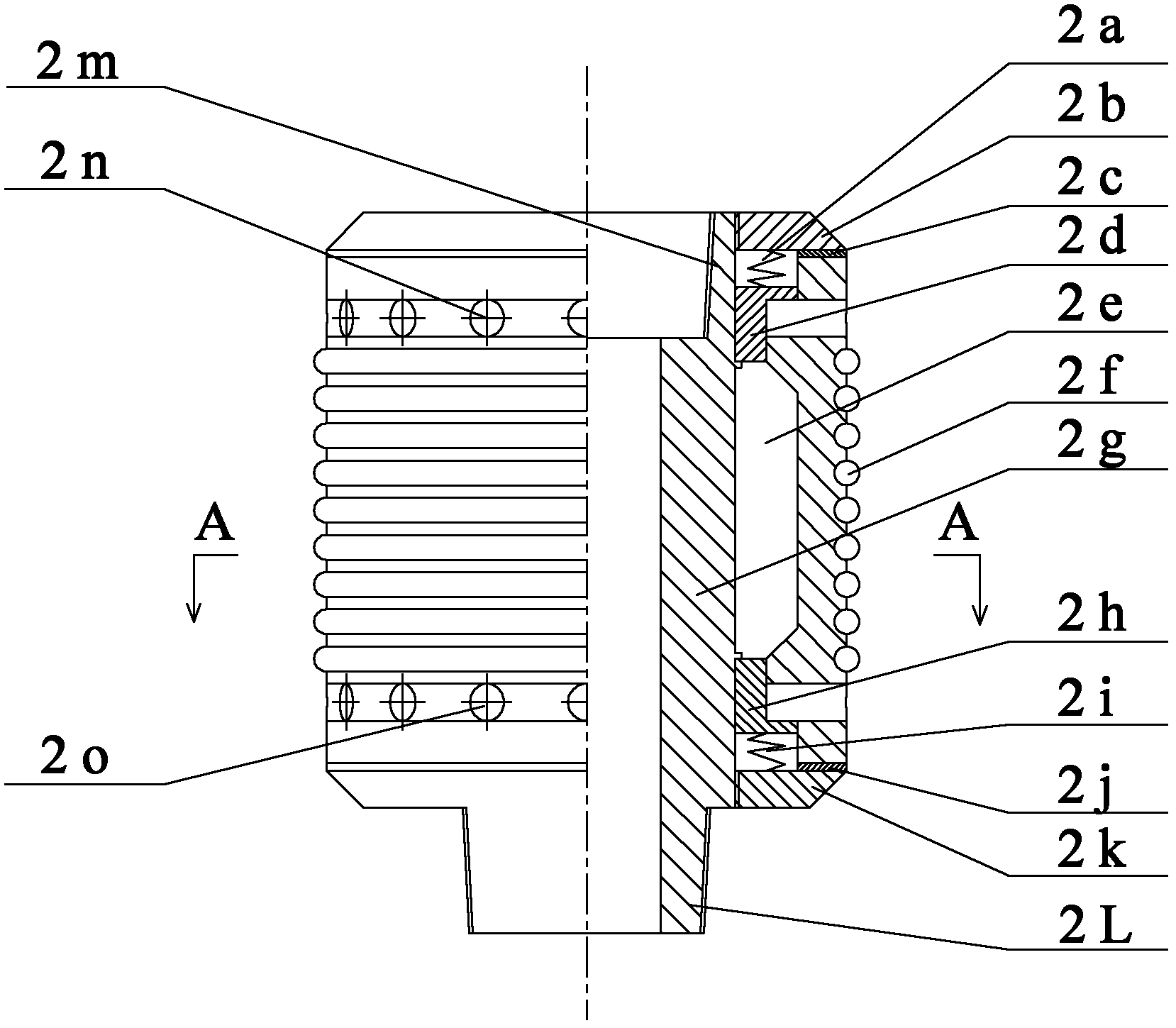

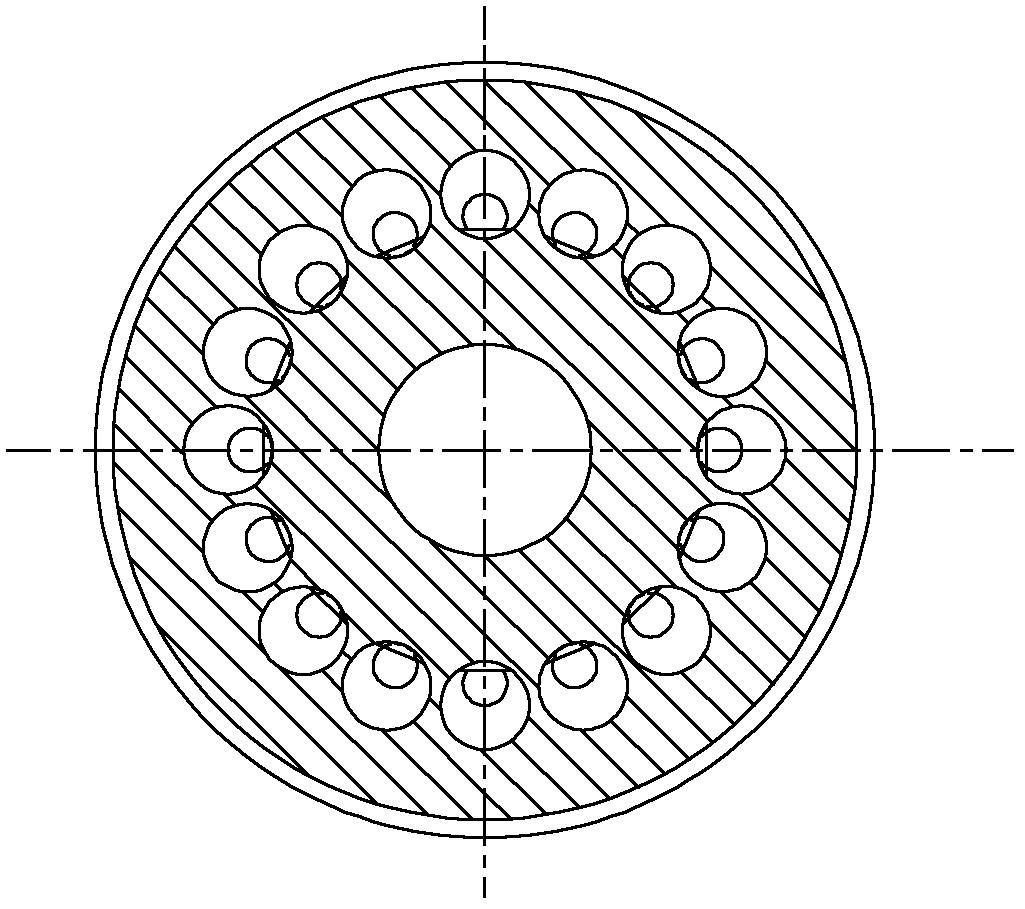

[0016] The present invention will be further described below in conjunction with the accompanying drawings: the injection pipe string of the present invention is mainly composed of a water well bidirectional anchor 1, an insertion sealer 2, a casing prefabricated sealing cylinder 3, a water distributor 4, an insertion sealer 5, and a casing prefabricated sealing cylinder 6. Water distributor 7, oil pipe 8, double ball seat 9, screen pipe 10, plug 11, casing 12, artificial well bottom 13, first-stage water injection section 14, and second-stage water injection section 15. Insert the sealer body 2g into the axially built-in overflow channel 2e, insert the upper end of the sealer body 2g to set the water inlet 2n to communicate with the overflow channel 2e, and insert the lower end of the sealer body 2g to set the water outlet 2o to communicate with the overflow channel 2e; The water inlet piston 2d is embedded in the round hole at the upper end of the overflow channel 2e, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com