Diaphragm type air suspension

An air suspension and suspension system technology, applied in the direction of shock absorbers, springs, springs/shock absorbers, etc., can solve the problems of complex design and high cost, achieve good heat dissipation, reduce space size, and increase durability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

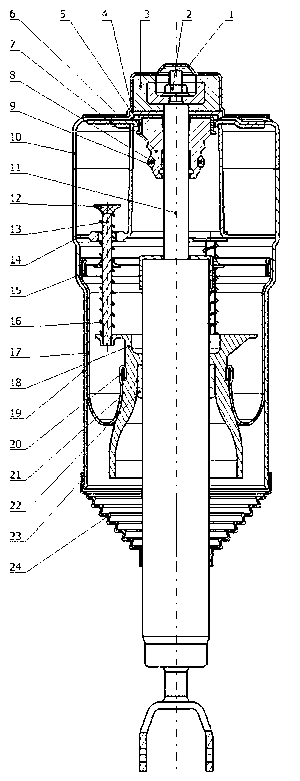

[0008] specific implementation plan

[0009] The suspension system is composed of damping elements, elastic elements, and buffer limit blocks.

[0010] The damping element partly realizes energy dissipation by the shock absorber (11).

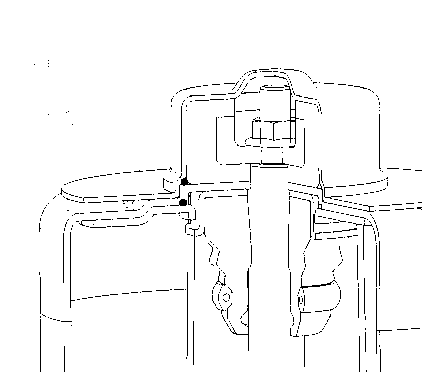

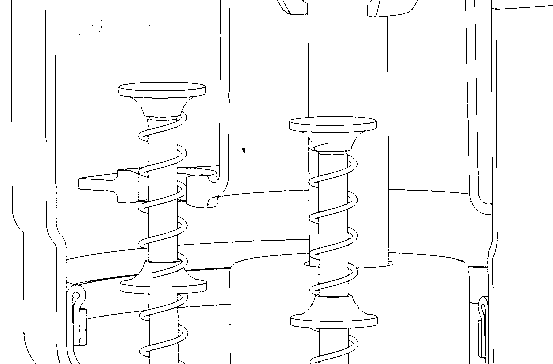

[0011] The elastic element part is mainly composed of an upper end cover (1), a rubber plug (12), a guide piston (18), and an air bag membrane (17). Fill the upper end cover (1) and the upper air chamber cover plate (10) with sealant (4) to complete the overall sealing of the air chamber. A body connection plate can be welded above it according to the body structure; the lower shock absorber is directly hinged on the lower swing arm. The upper lock nut (2) fixes the damping bearing (3) on the top of the shock absorber to absorb vertical torque and noise. The air bag (17) is respectively installed on the air chamber housing (15) and the guide piston (18) through snap rings (15) and (20). The rubber plug (12) passes through the auxiliary air...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com