Friction moment measurement method for life evaluation of motor ball bearing

A friction torque, ball bearing technology, applied in the field of measurement, can solve the problems of lack of strict control and poor pertinence, and achieve the effect of high measurement efficiency and precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

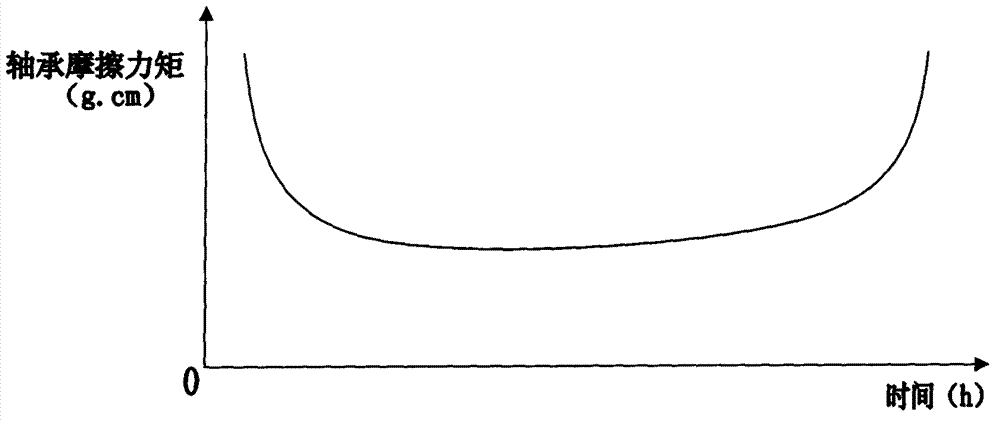

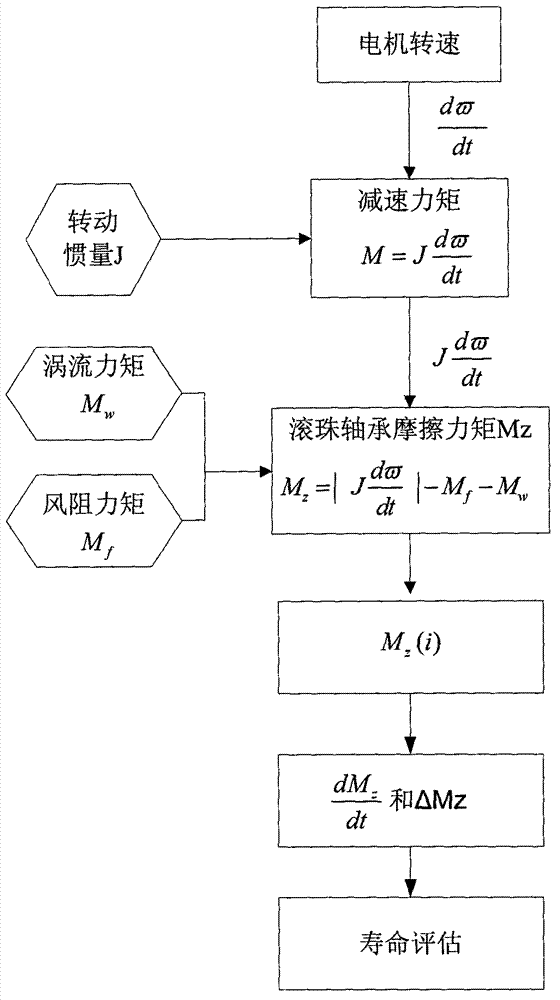

[0015] The measurement principle of the present invention is: during the running-in period of the motor, the speed of the growth and change rate of the friction torque of each motor bearing is determined by a speed measurement method. There are many methods of motor speed measurement, such as photoelectric code disc speed measurement, photoelectric speed measurement, back EMF speed measurement, etc. The installation of the photoelectric code disc on the motor shaft will bring additional moment of inertia; the photoelectric speed measurement must spray or etch some kind of non-reflective mark on the surface of the motor; The motor speed is measured by the potential cycle method or the photoelectric velocimetry method, and then the friction torque of the ball bearing is obtained by using the speed change rate, so as to obtain the change rate of the ball bearing friction torque with the working time, and then give the conclusion of the service life evaluation of the ball bearing f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com