All-fiber current transformer and half-wave voltage correction method thereof

A current transformer and half-wave voltage technology, which is applied in the field of all-optical current transformer and its half-wave voltage correction, can solve the problems of low accuracy and low efficiency of half-wave voltage, and achieve the effect of improving measurement efficiency and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] All fiber optic current transformer embodiment:

[0034] The all-fiber-optic current transformer proposed in this embodiment includes a light source, an optical-fiber sensing ring (sensing ring for short), a phase modulator, a photodetector, and a controller. The controller includes a memory and a processor, and the processor is used to execute instructions stored in the memory to realize the half-wave voltage correction method of the all-fiber current transformer.

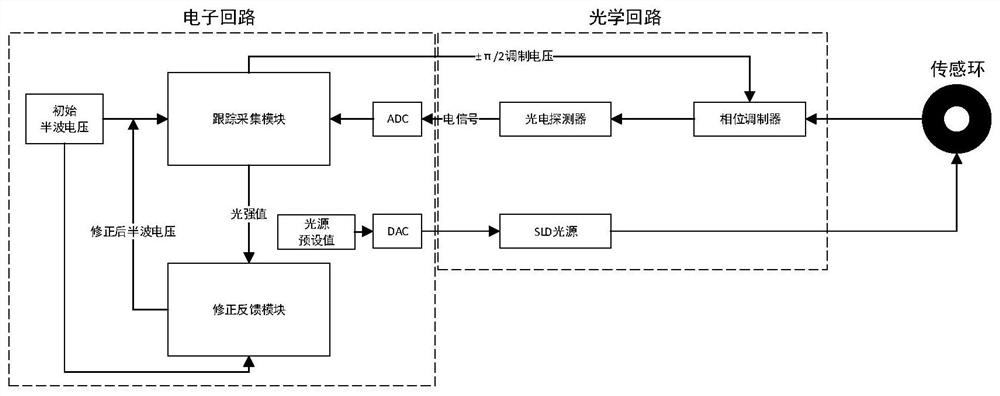

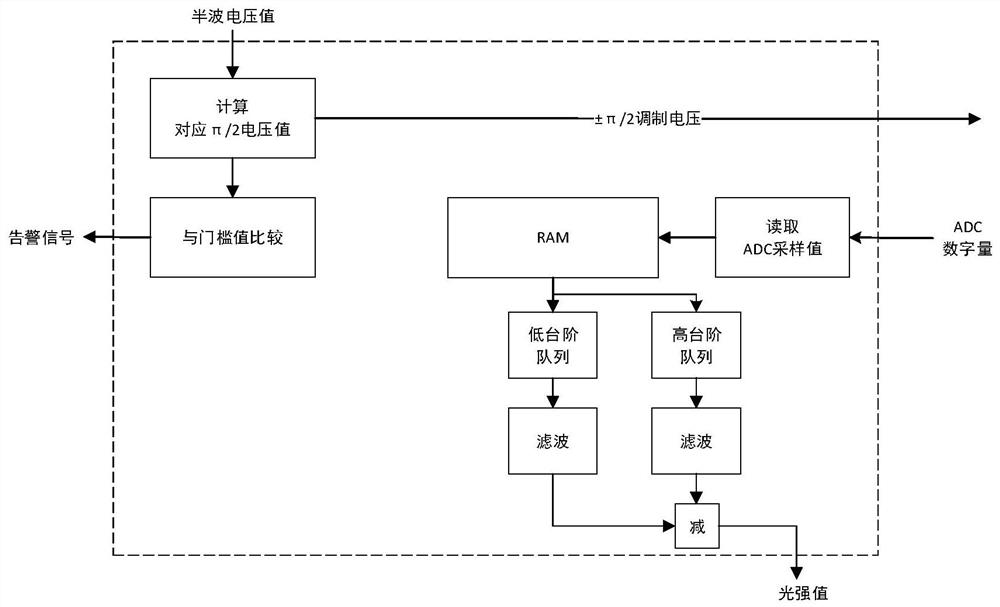

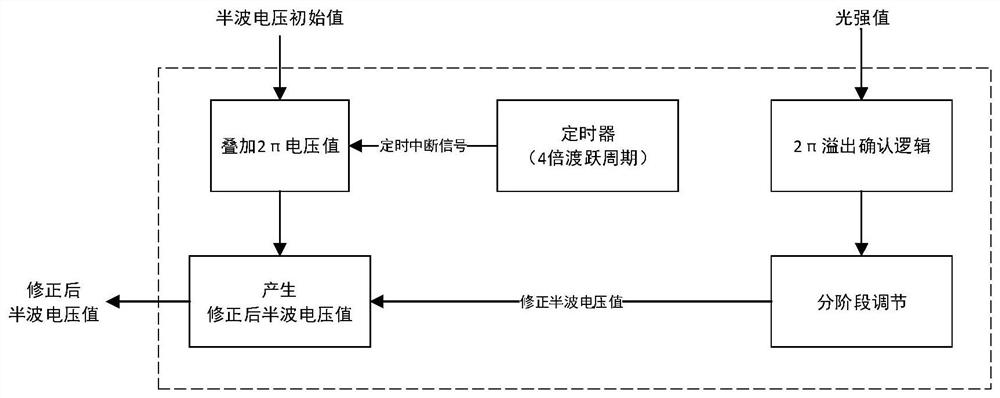

[0035] The all-fiber-optic current transformer utilizes Faraday's magneto-optic effect principle and interferometry principle to close-loop control the internal optical signal, and demodulates the implied current information from it. The specific structure of the all-fiber current transformer is as follows: figure 1 As shown, it includes an electronic circuit, an optical circuit, and a sensing ring; the optical circuit includes an SDL light source, a phase modulator, and a fiber optic detector; the electro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com