Fault detection system, fault detection method and module

A technology of fault detection and blockage detection, which is applied in the direction of measuring devices, measuring heat, testing of machine/structural components, etc., and can solve problems such as blockage and faults

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

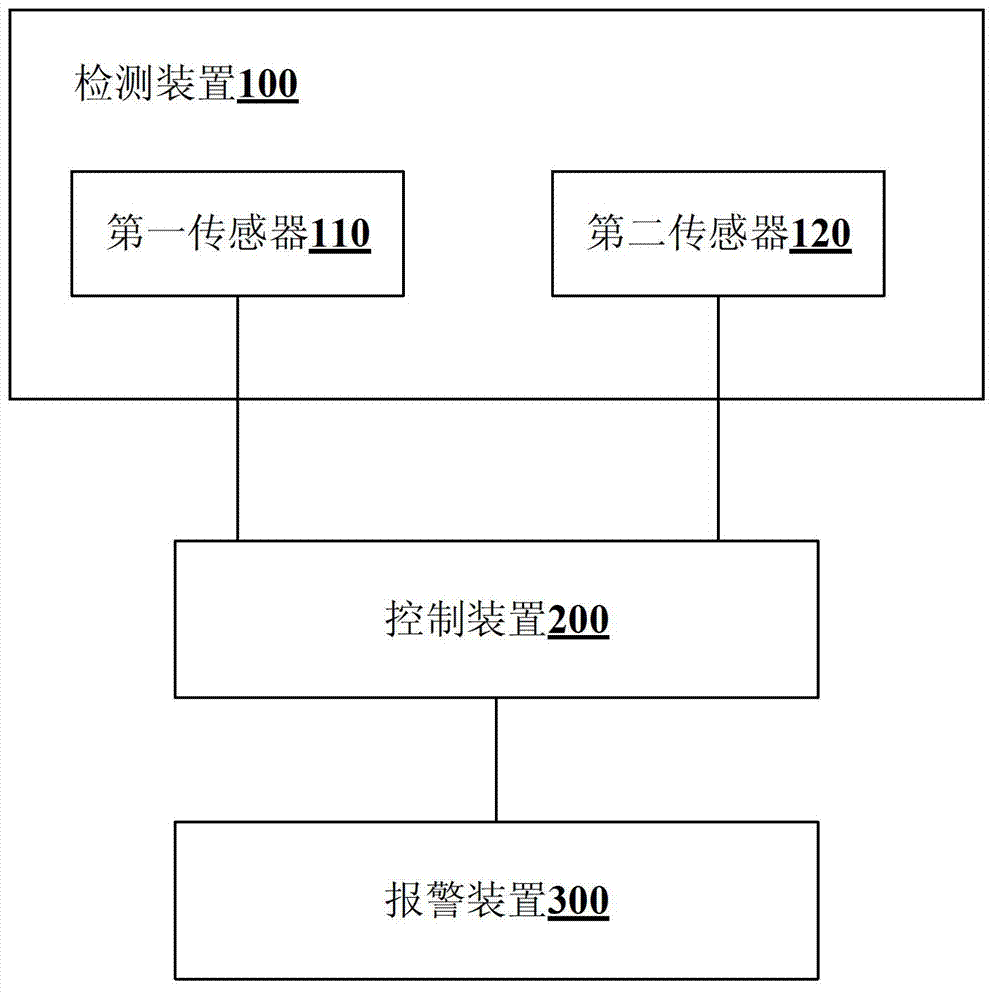

[0024] refer to figure 1 . The fault detection system of this embodiment is used for the blockage detection of temperature adjustment equipment, and includes a detection device 100 , a control device 200 and an alarm device 300 .

[0025] Wherein, the detecting device 100 includes a first temperature sensor 110 disposed at the inlet of the temperature regulating device and a second temperature sensor 120 disposed at the outlet of the temperature regulating device. The control device 200 is connected to the first temperature sensor 110 and the second temperature sensor 120, and is used to send a first alarm driving signal when the temperature difference between the inlet and outlet of the temperature adjustment device is lower than the minimum value of the predetermined normal temperature drop; or, It is used to issue an alarm and a second alarm driving signal when the inlet temperature of the temperature adjustment equipment is higher than the maximum value of the predetermin...

no. 2 example

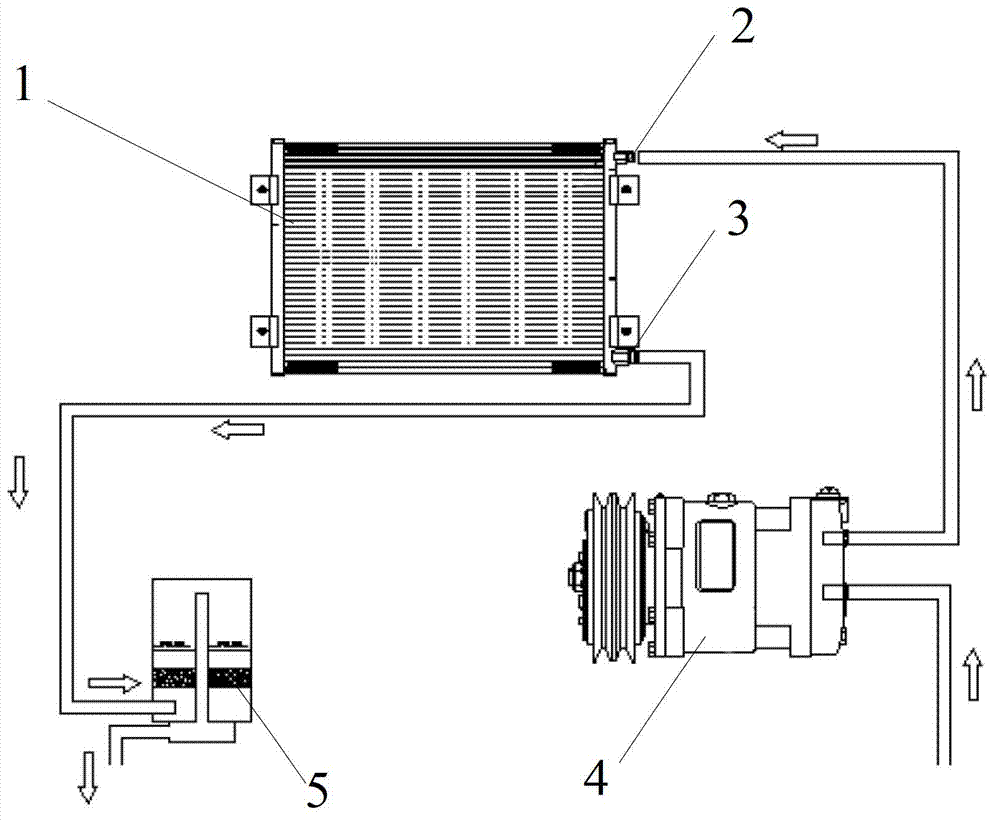

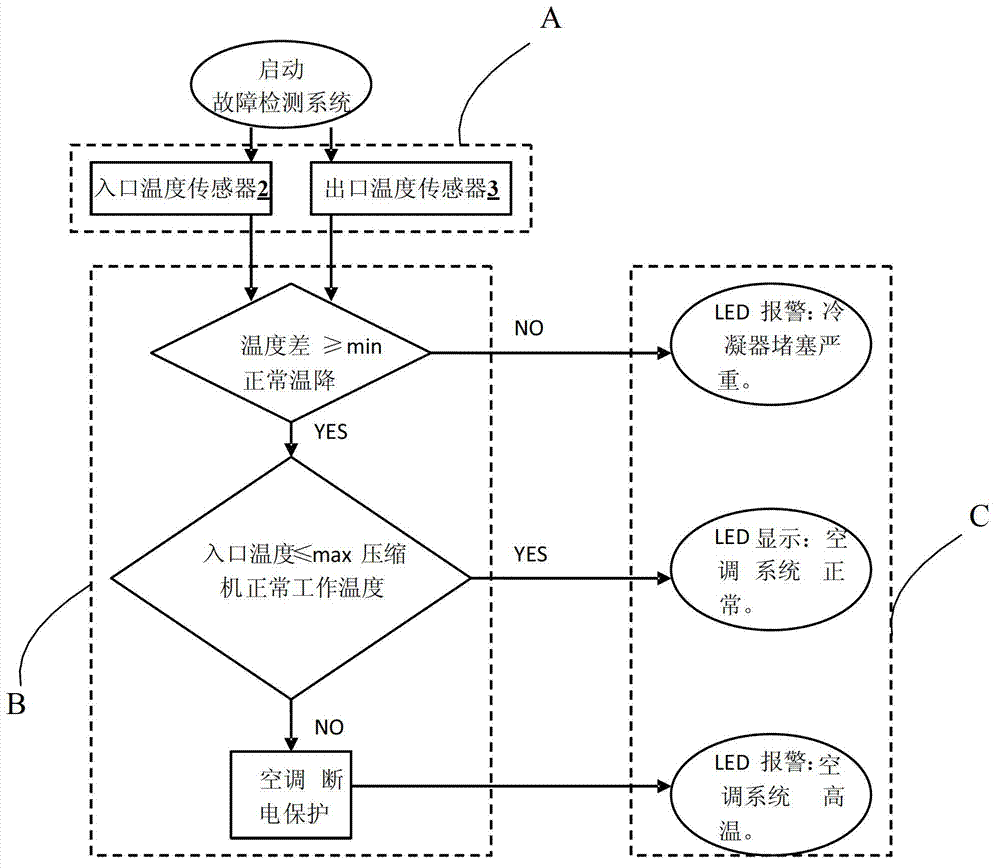

[0028] refer to figure 2 with image 3 .

[0029] In this embodiment, an air conditioner condenser is taken as an example to describe the specific application of the fault detection system in detail.

[0030] In this system, temperature sensor 2 and temperature sensor 3 need to be installed at the outlet and inlet of condenser 1 respectively. The installation positions are as follows: figure 2 shown. In the air conditioning system, the inlet temperature of condenser 1 is about 80°C, and the outlet temperature of the condenser is about 60°C or less. The temperature difference between the two inlets and outlets is relatively large, so it is more accurate to judge the clogging degree of the condenser according to whether the temperature difference is normal or not. In addition, a drying bottle 5 is also connected to the outlet of the condenser.

[0031] The inlet of the condenser 1 is connected to the compressor 4, which is the highest temperature point during the cooling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com