Method for rapid detection of impact performance of automobile modified plastic

A technology of impact performance and detection method, which is applied in the direction of testing the strength of materials with one impact force, and can solve the problems of long time required for health preservation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

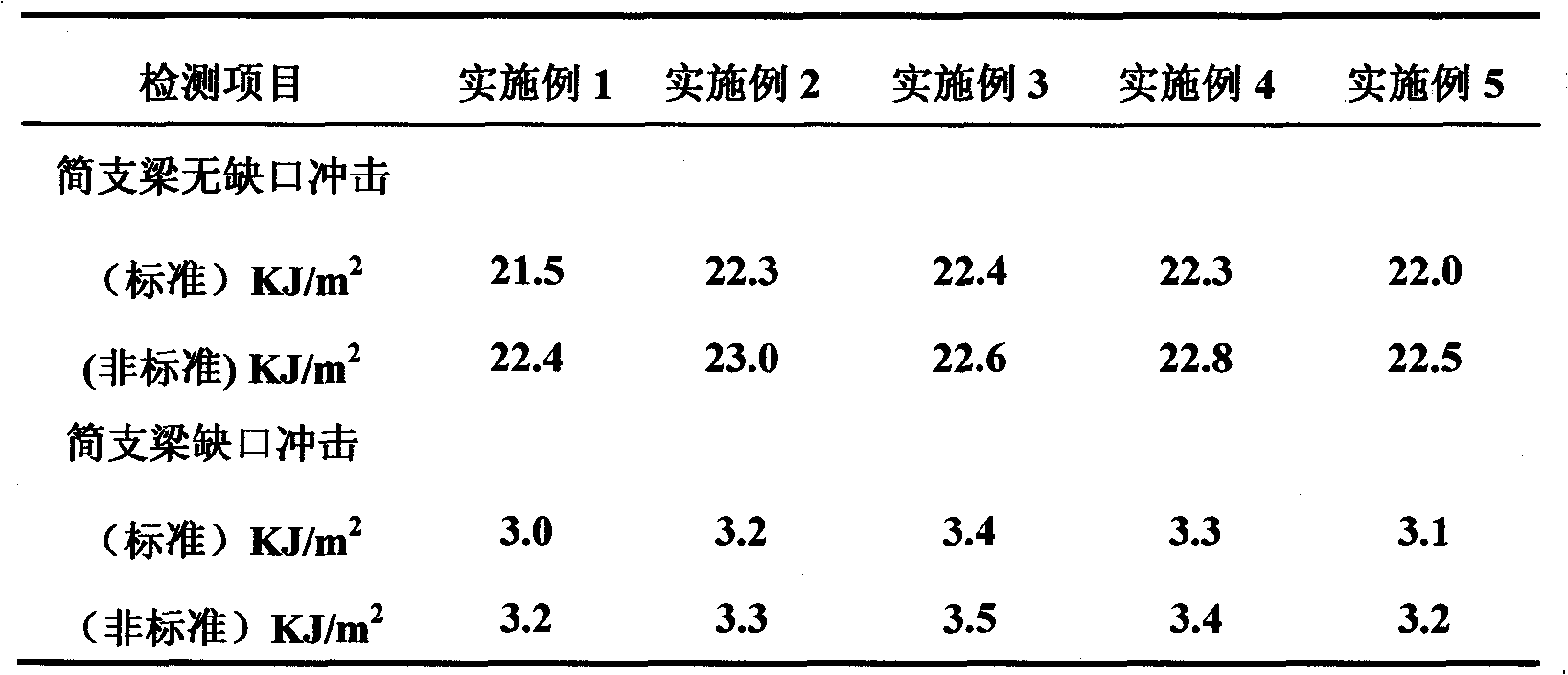

Embodiment 1

[0010] Mix 40 parts of Daqing Petrochemical Z30S resin, 25 parts of Daqing Petrochemical T30S, and 32 parts of talcum powder in a high-speed mixer for 2 to 5 minutes, and then discharge the mixture. The screw speed of the machine is 200-350r / min, and the barrel temperature is 190-230°C. Injected parts under standard and non-standard conditions, under standard climate conditions with a temperature of (23±2)°C and a relative humidity of (50±6)%, the impact span: (40±2)mm; impact energy : 0.5J~4J; impact velocity: 2.9m / s or 3.8m / s; sample thickness ≥ 4mm or ≥ 2.66mm; ±2°, no less than 6 samples for each group; during the test, the impact blade is aligned with the center of the sample, and the impact blade of the notched sample is aligned with the center of the back of the notch. If pores appear after the sample is damaged, it should be marked and discarded, and another sample should be taken to make up. The impact performance test results are shown in Table 1.

Embodiment 2

[0012] Mix 15 parts of Z30S resin of Daqing Petrochemical, 50 parts of T30S of Daqing Petrochemical, 38 parts of talcum powder, and 7 parts of POE, and mix them with a high-speed mixer for 2 to 5 minutes before discharging. The mixture is extruded and granulated through a twin-screw extruder with a diameter of 30 mm. , the screw speed of the extruder is 200-350r / min, and the barrel temperature is 190-230°C. Injected parts under standard and non-standard conditions, under standard climate conditions with a temperature of (23±2)°C and a relative humidity of (50±6)%, the impact span: (40±2)mm; impact energy : 0.5J~4J; impact velocity: 2.9m / s or 3.8m / s; sample thickness ≥ 4mm or ≥ 2.66mm The impact blade is in contact with the striking surface of the sample, the contact line is perpendicular to the long axis of the sample, and the deviation is not more than ± 2°, no less than 6 samples for each group; during the test, the impact blade is aligned with the center of the sample, and ...

Embodiment 3

[0014] Mix 50 parts of Daqing Petrochemical T30S, 15 parts of Dalian Mankerui Z69S, 38 parts of talcum powder, and 7 parts of POE, and mix them with a high-speed mixer for 2 to 5 minutes before discharging. The mixture is extruded through a twin-screw extruder with a diameter of 30 mm For granulation, the screw speed of the extruder is 200-350r / min, and the barrel temperature is 190-230°C. Injected parts under standard and non-standard conditions, under standard climate conditions with a temperature of (23±2)°C and a relative humidity of (50±6)%, the impact span: (40±2)mm; impact energy : 0.5J~4J; impact velocity: 2.9m / s or 3.8m / s; sample thickness ≥ 4mm or ≥ 2.66mm; ±2°, no less than 6 samples for each group; during the test, the impact blade is aligned with the center of the sample, and the impact blade of the notched sample is aligned with the center of the back of the notch. If pores appear after the sample is damaged, it should be marked and discarded, and another sample...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Total length | aaaaa | aaaaa |

| Impact energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com