A kind of super-tough fiber composite resin concrete and its preparation method

A technology of resin concrete and fiber composite, which is applied in the field of super-tough fiber composite resin concrete and its specific preparation, can solve problems such as fatigue cracks, macro fatigue cracks, fatigue damage, etc. Effect of improving crack resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

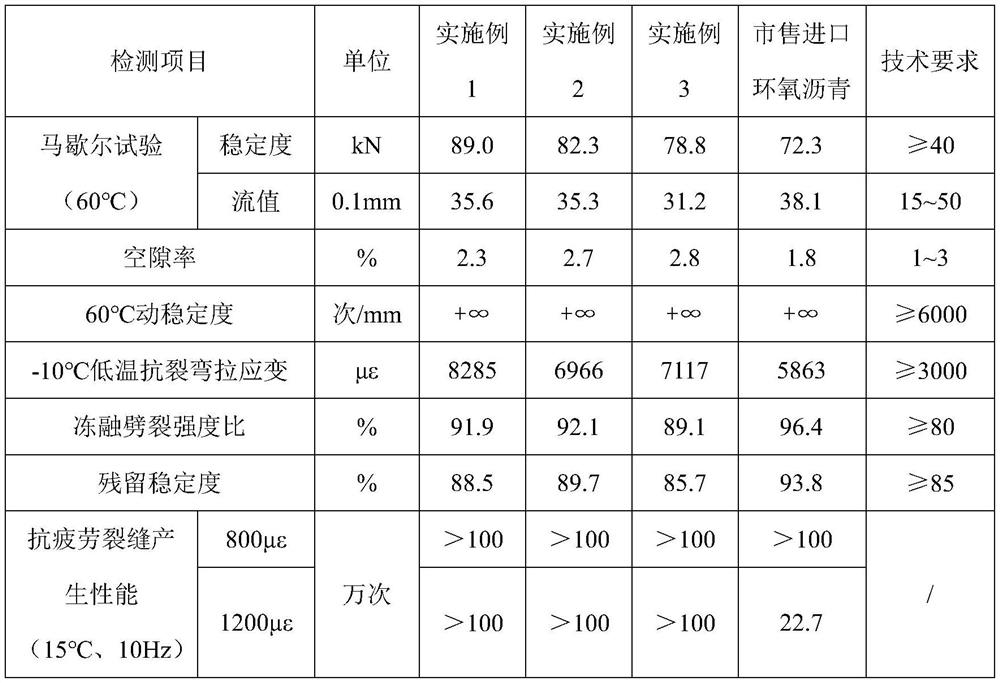

Embodiment 1

[0061] The super-tough fiber composite resin concrete of the present invention comprises 11 parts by mass of super-tough acrylic resin slurry, 1 part of high modulus hybrid chopped fiber, 100 parts of graded mineral material, 12 parts of rubber powder, and 0.1 part of anti-ultraviolet auxiliary agent .

[0062] Among them, the ultra-tough acrylic resin slurry is made by mixing the modified acrylic resin MMR toughened by the active polyether flexible segment and the polyurethane monomer PU at a mass ratio of 5:3 at 40°C-50°C; the high modulus hybrid chopped The fiber is made by mixing glass fiber GF surface treated with oily diaminosilane coupling agent, basalt fiber BF and carbon fiber CF treated with oily epoxy silane coupling agent at a mass ratio of 0.35:1:0.65; gradation The mineral material is composed of basalt aggregates of different particle sizes and mineral powder dry mixed in the mass ratio (5-10mm):(3-5mm):(0-3mm):mineral powder=25:21.5:45:8.5.

[0063] The super-...

Embodiment 2

[0068] The super-tough fiber composite resin concrete of the present invention comprises 12 parts by mass of super-tough acrylic resin slurry, 1.5 parts of high modulus hybrid chopped fibers, 100 parts of graded mineral material, 13.5 parts of rubber powder, and 0.1 part of anti-ultraviolet auxiliary agent .

[0069] Among them, the ultra-tough acrylic resin slurry is made by mixing the modified acrylic resin MMR toughened by the active polyether flexible segment and the polyurethane monomer PU at a mass ratio of 5:3 at 40°C-50°C; the high modulus hybrid chopped The fiber is made by mixing glass fiber GF surface treated with oily diaminosilane coupling agent, basalt fiber BF and carbon fiber CF treated with oily epoxy silane coupling agent at a mass ratio of 0.35:1:0.65; gradation The mineral material is composed of basalt aggregates of different particle sizes and mineral powder dry mixed in the mass ratio (5-10mm):(3-5mm):(0-3mm):mineral powder=25:21.5:45:8.5.

[0070] The ...

Embodiment 3

[0075] The super-tough fiber composite resin concrete of the present invention comprises 14 parts by mass of super-tough acrylic resin slurry, 2 parts of high modulus hybrid chopped fibers, 100 parts of graded mineral materials, 15.5 parts of rubber powder, and 0.12 parts of anti-ultraviolet auxiliary agent .

[0076] Among them, the ultra-tough acrylic resin slurry is made by mixing the modified acrylic resin MMR toughened by the active polyether flexible segment and the polyurethane monomer PU at a mass ratio of 5:3 at 40°C-50°C; the high modulus hybrid chopped The fiber is made by mixing glass fiber GF surface treated with oily diaminosilane coupling agent, basalt fiber BF and carbon fiber CF treated with oily epoxy silane coupling agent at a mass ratio of 0.35:1:0.65; gradation The mineral material is composed of basalt aggregates of different particle sizes and mineral powder dry mixed in the mass ratio (5-10mm):(3-5mm):(0-3mm):mineral powder=25:21.5:45:8.5.

[0077] The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com