Polaroid and manufacturing methods of display panel and polaroid

A manufacturing method and display panel technology, applied in the direction of optics, polarizing elements, nonlinear optics, etc., can solve the problems of inability to complete the glass cutting process, increase the workload of operators, and inability to use stress cutting, etc., so as to reduce the number of attachments, The effect of reducing attachment time and reducing workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] In this embodiment, the polarizer includes a base and a polarizing film layer arranged on the base, the polarizing film layer includes a plurality of unit polarizing film layers, and the positions of the plurality of unit polarizing film layers on the base and The positions of multiple display panels in the liquid crystal cell (the liquid crystal cell can be divided into multiple display panels, and the liquid crystal cell has not been cut here) correspond to the positions respectively, and the area of the polarizing film layer of each unit is less than or equal to its corresponding display The area of the panel is larger than the area of the corresponding effective display area of the display panel (the display panel can be divided into an active area (A / A, active area) and a peripheral area). Preferably, the distance between every two unit polarizing film layers 3 a is 5 mm to 20 mm.

[0062] This embodiment also provides a method for manufacturing a display p...

Embodiment 2

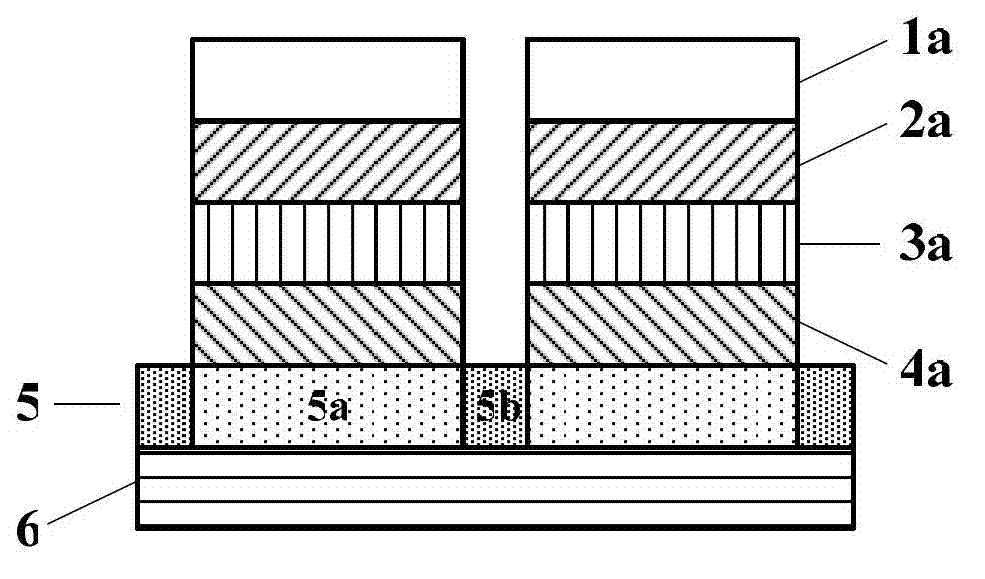

[0069] like figure 1 As shown, in this embodiment, the polarizer includes a surface protection layer, a first polarizing film protective layer, a polarizing film layer, a second polarizing film protective layer, a substrate 5 and a peeling layer (i.e. figure 1 The first peeling layer in 6).

[0070] The polarizing film layer includes a plurality of unit polarizing film layers 3a, the plurality of unit polarizing film layers 3a correspond to the positions of a plurality of display panels in the liquid crystal cell respectively, and the area of each unit polarizing film layer 3a is less than or equal to its corresponding to the area of the display panel. Preferably, the distance between every two unit polarizing film layers 3a is 5 mm to 20 mm (ie Figure 4 Dimension d) in (b).

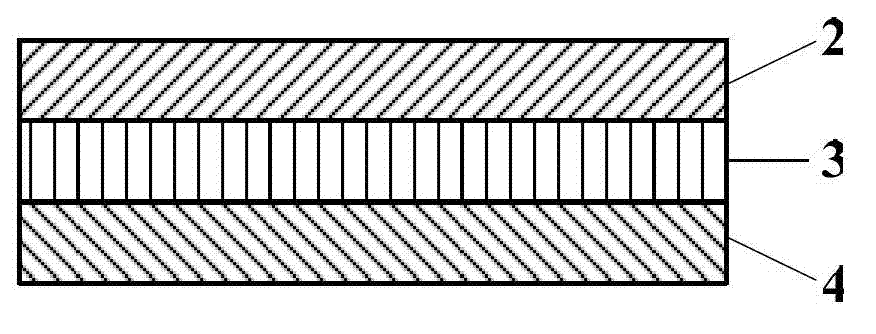

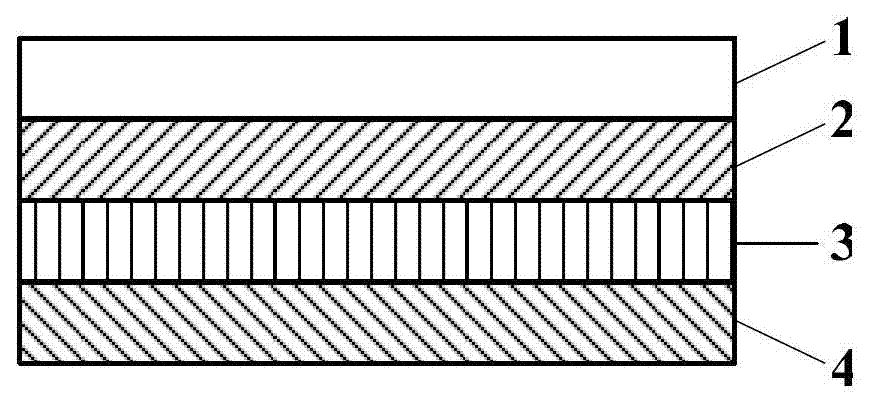

[0071] The first polarizing film protective layer and the second polarizing film protective layer are respectively attached to both sides of the polarizing film layer; the first polarizing film p...

Embodiment 3

[0105] The difference between the polarizer described in this embodiment and Embodiment 2 is:

[0106] The polarizer also includes a first adhesive layer and a functional film layer, the functional film layer is used to increase the intensity of transmitted light, or to increase the intensity of reflected light, or to compensate for optical phase difference, or to increase both the intensity of transmitted light Intensity in turn increases the reflected light intensity. Preferably, the functional film layer is an anti-reflective film, a reflective film, a phase compensation film or a semi-transparent and semi-reflective film. The first adhesive layer and the functional film layer are sequentially arranged between the second polarizing film protective layer 4 and the substrate 5, that is, the first adhesive layer is attached to the second polarizing film protective layer 4 on the side away from the polarizing film layer 3 , the functional film layer is attached on the side of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com