Chopper circuit for power generator exciting current

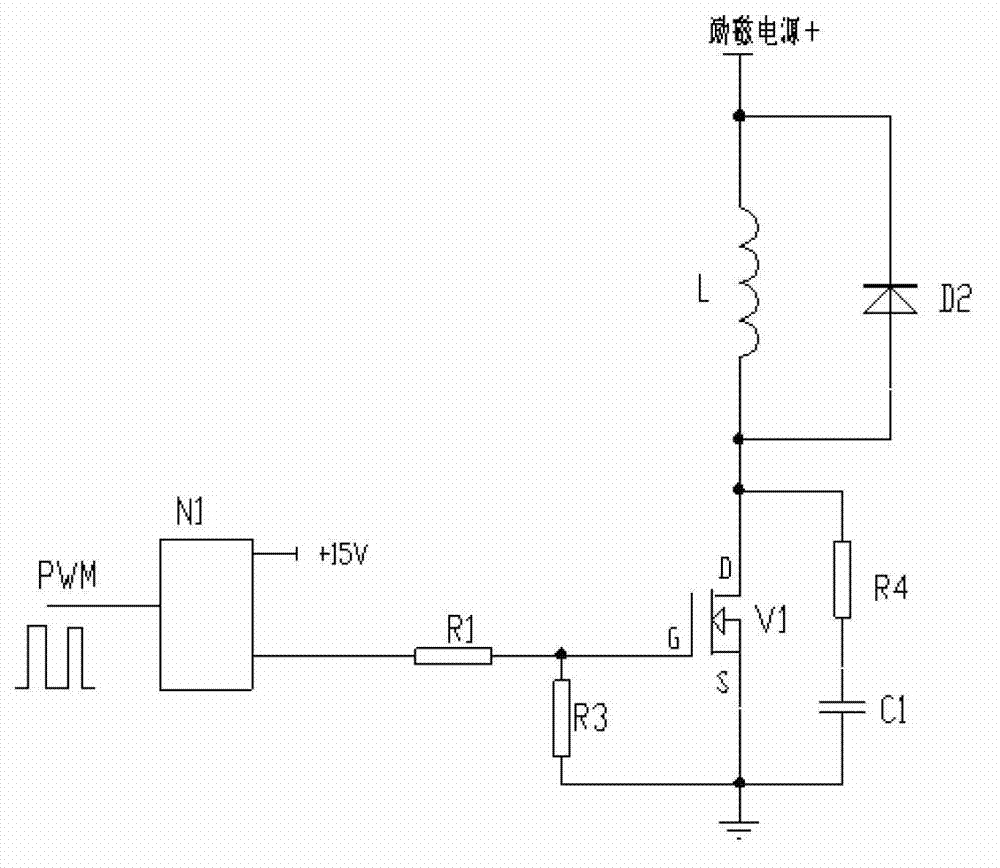

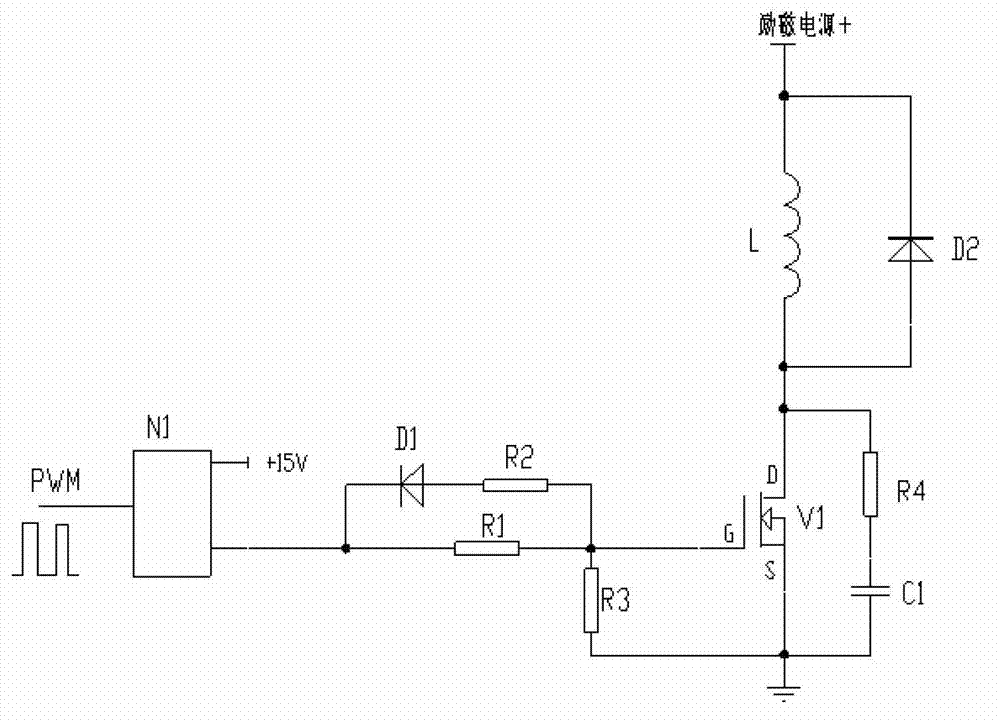

A technology of excitation current and chopper circuit, which is applied to control the direction of the generator through the change of the magnetic field, can solve the problems of slow turn-off process of the field effect tube V1, long turn-off time, and large loss of the field effect tube V1, and shorten the turn-off The effect of shortening the turn-off time, accelerating the turn-off process, and reducing loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] Example 1, the resistance of R1 and R2 is 20Ω, the resistance of R3 is 5.1KΩ, the model of D1 is 2CN3F, the model of V1 is IXKK85N60C, the DS voltage is 150V when the field effect tube V1 is turned off, and the average current of V1 is 20A. The turn-off time of the field effect tube is reduced from 100ns to 55ns.

Embodiment 2

[0014] Example 2: The resistance of R1 and R2 is 100Ω, the resistance of R3 is 5.1KΩ, the model of D1 is 2CN3F, the model of V1 is IRF460, the DS voltage is 110V when the field effect tube V1 is turned off, and the average current of V1 is 5A. The turn-off time of the field effect tube is reduced from 51ns to 30ns.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com