Manufacturing method and structure of metal wire ball seat cushion

The technology of a wire ball and a manufacturing method, which is applied to mattresses, spring mattresses, other seating furniture, etc., can solve the problems of inability to discharge and diffuse heat and moisture accumulation, and achieve the effect of eliminating long-term driving fatigue.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The implementation of a metal wire ball seat pad structure will be further described below in conjunction with the accompanying drawings.

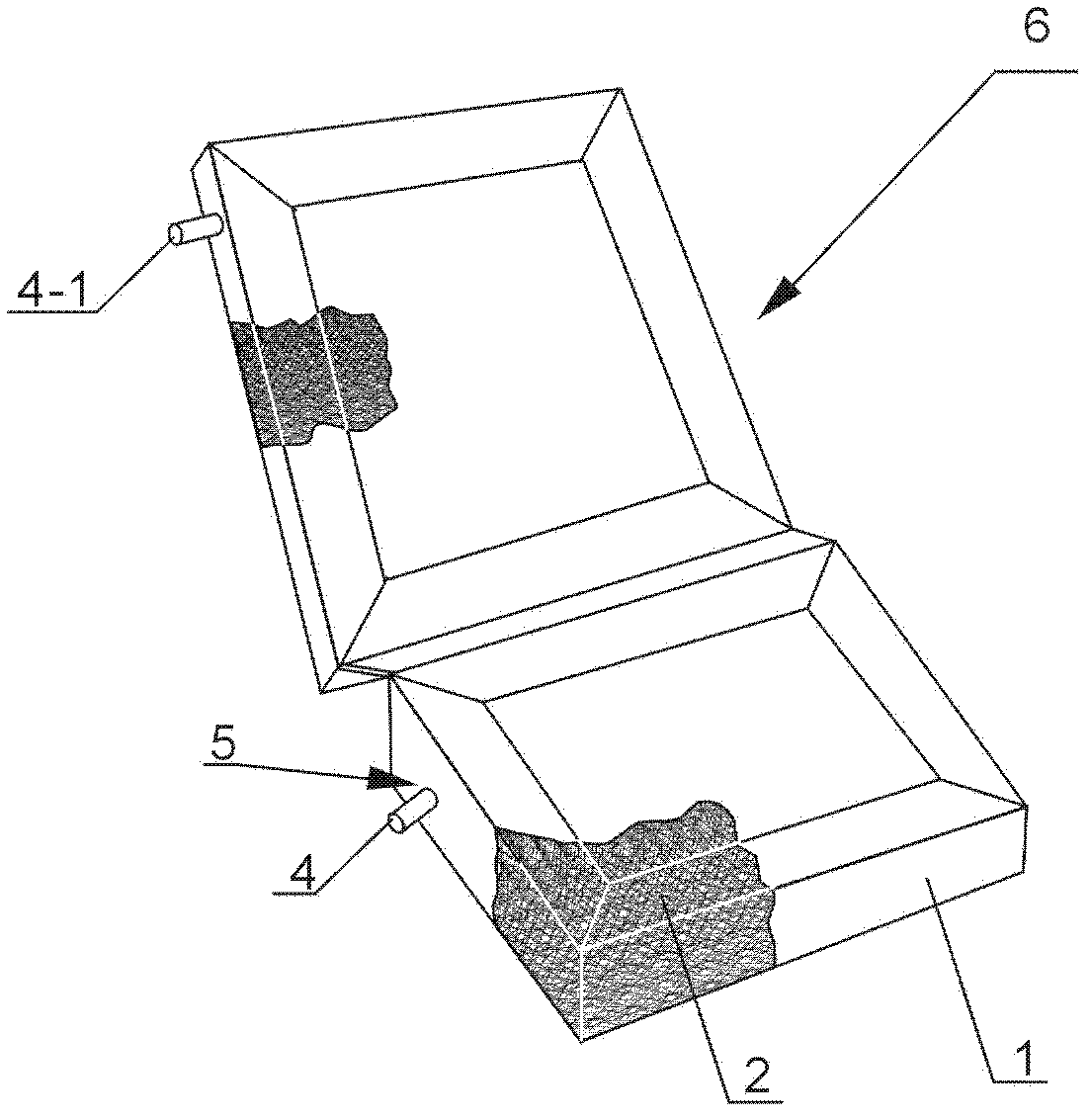

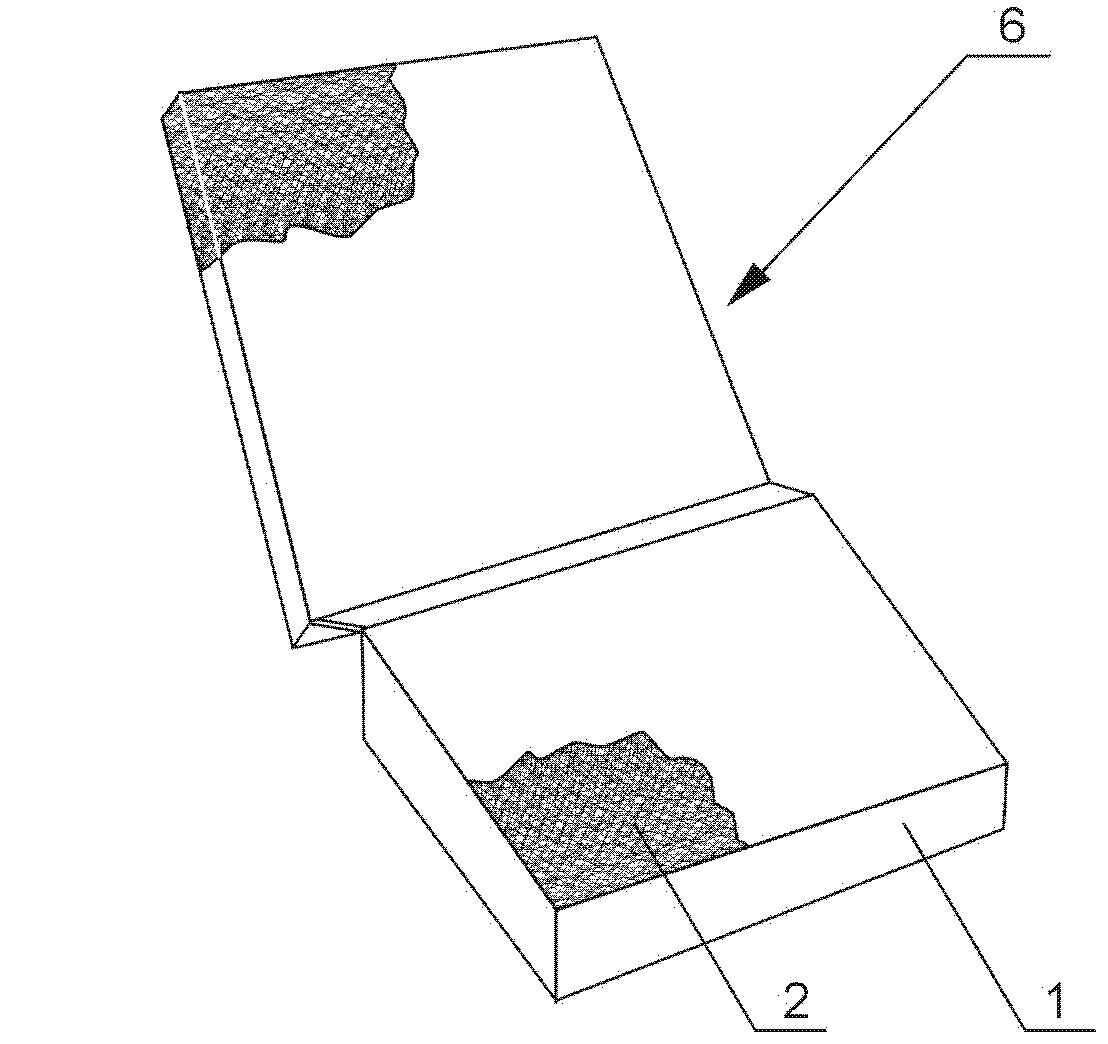

[0026] figure 1 Shown is a metal steel ball cushion shape structure, including a cushion cover 1, the cushion cover 1 wraps the seat cushion 2, the rear end surface of the seat cushion 2 is uprightly placed with a metal wire ball back cushion 5, one side of the cushion cover and An air inlet 4 connected to the air-conditioning duct is installed, and an air inlet 4-1 connected to the air-conditioning duct is installed on one side of the cushion.

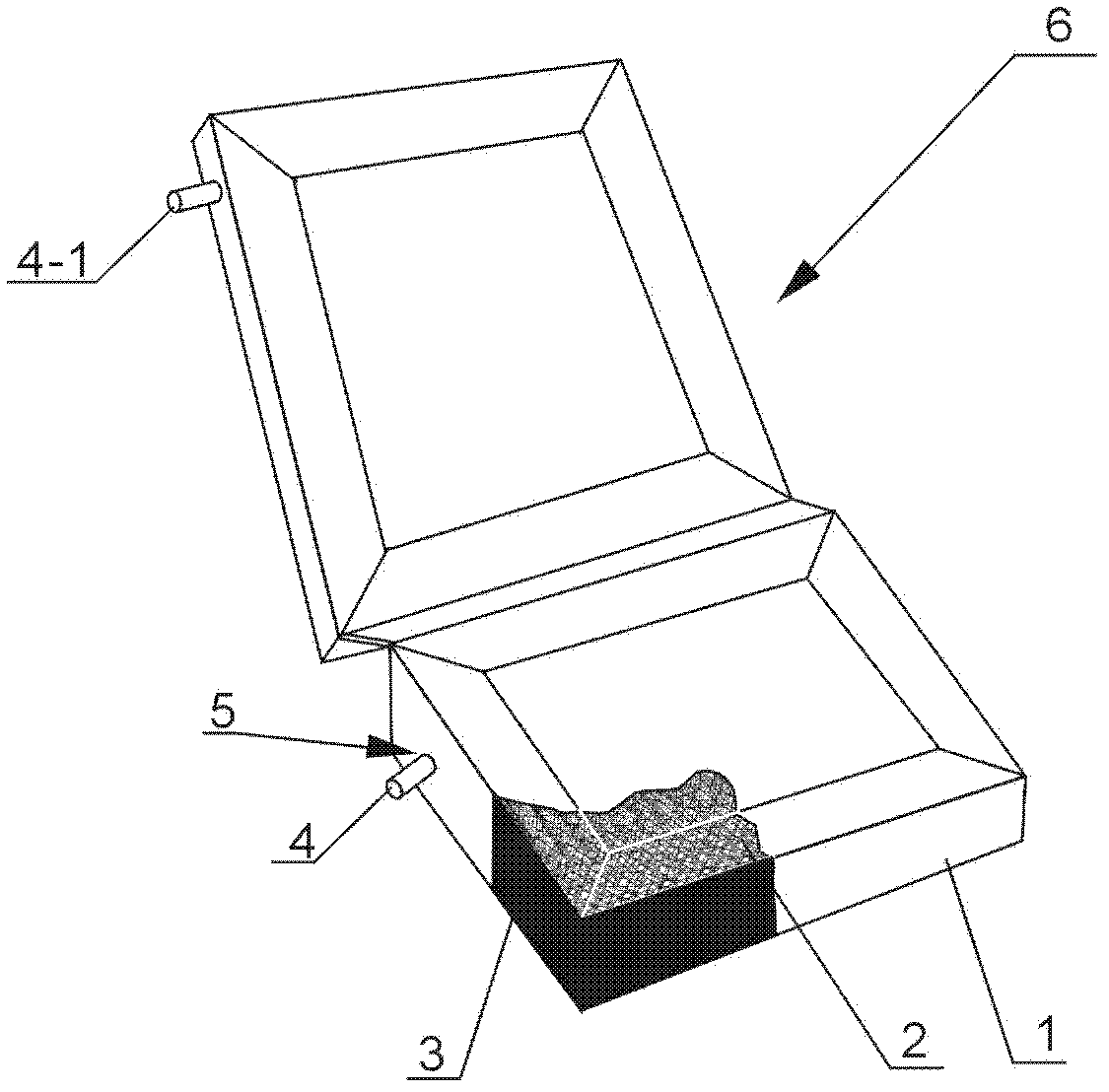

[0027] figure 2 Shown is a metal steel wire ball seat cushion structure, including a metal steel wire ball-shaped seat cushion 2, a cushion cover 1, a cushion circumference 3 is arranged around the seat cushion 2, and the seat cushion cover 1 wraps the seat cushion 2. One side of the seat cushion circumference 3 is installed with a hot and cold air inlet 4 connected to the air-conditioni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com