Continuous stirring granulator

A technology of granulator and granulation chamber, which is applied in the direction of granulation in static tanks/troughs, etc., which can solve problems such as flying dust, polluting the environment, and wide particle size distribution of products, so as to reduce material loss, reduce dust flying, and produce The effect of stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

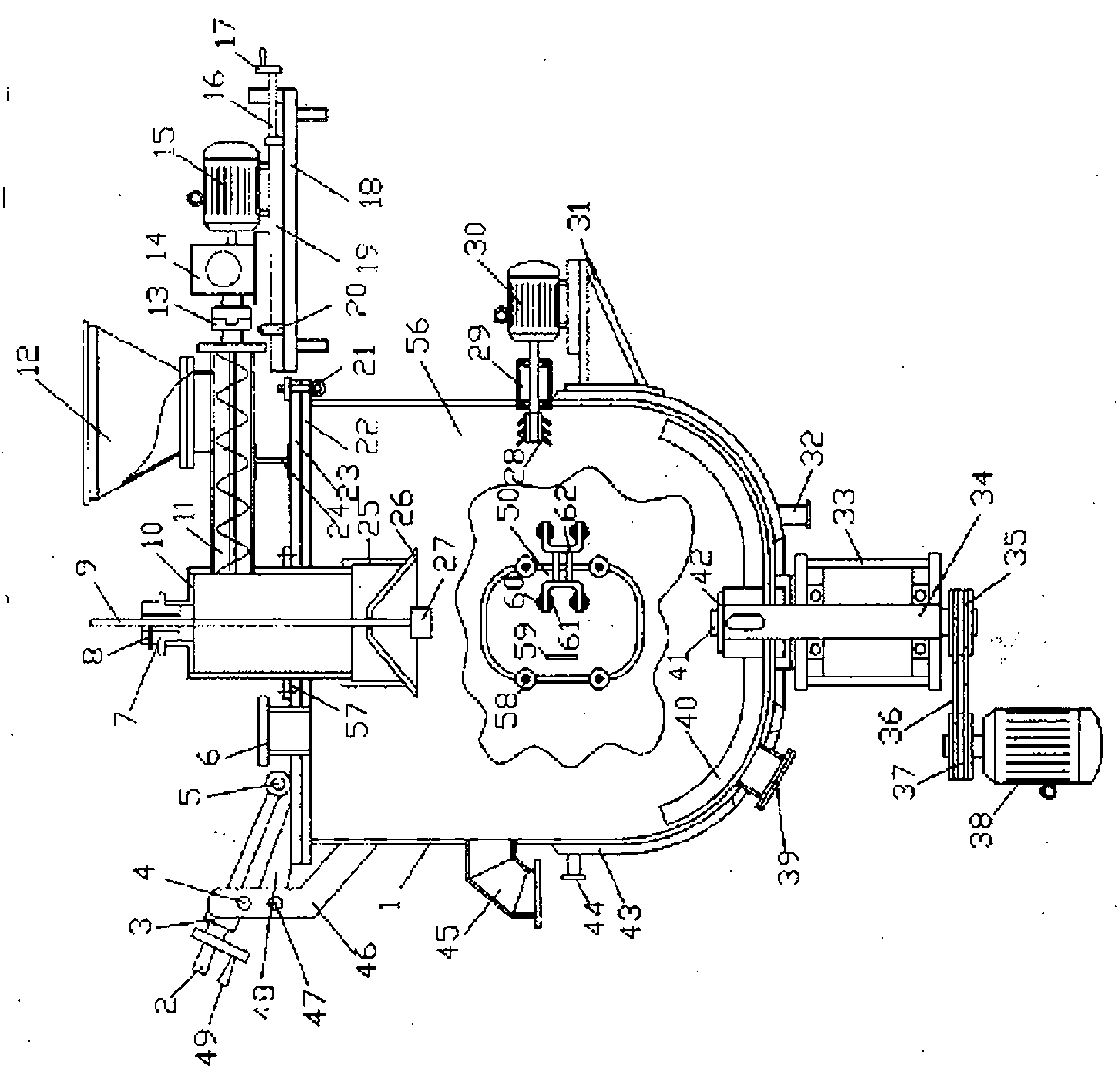

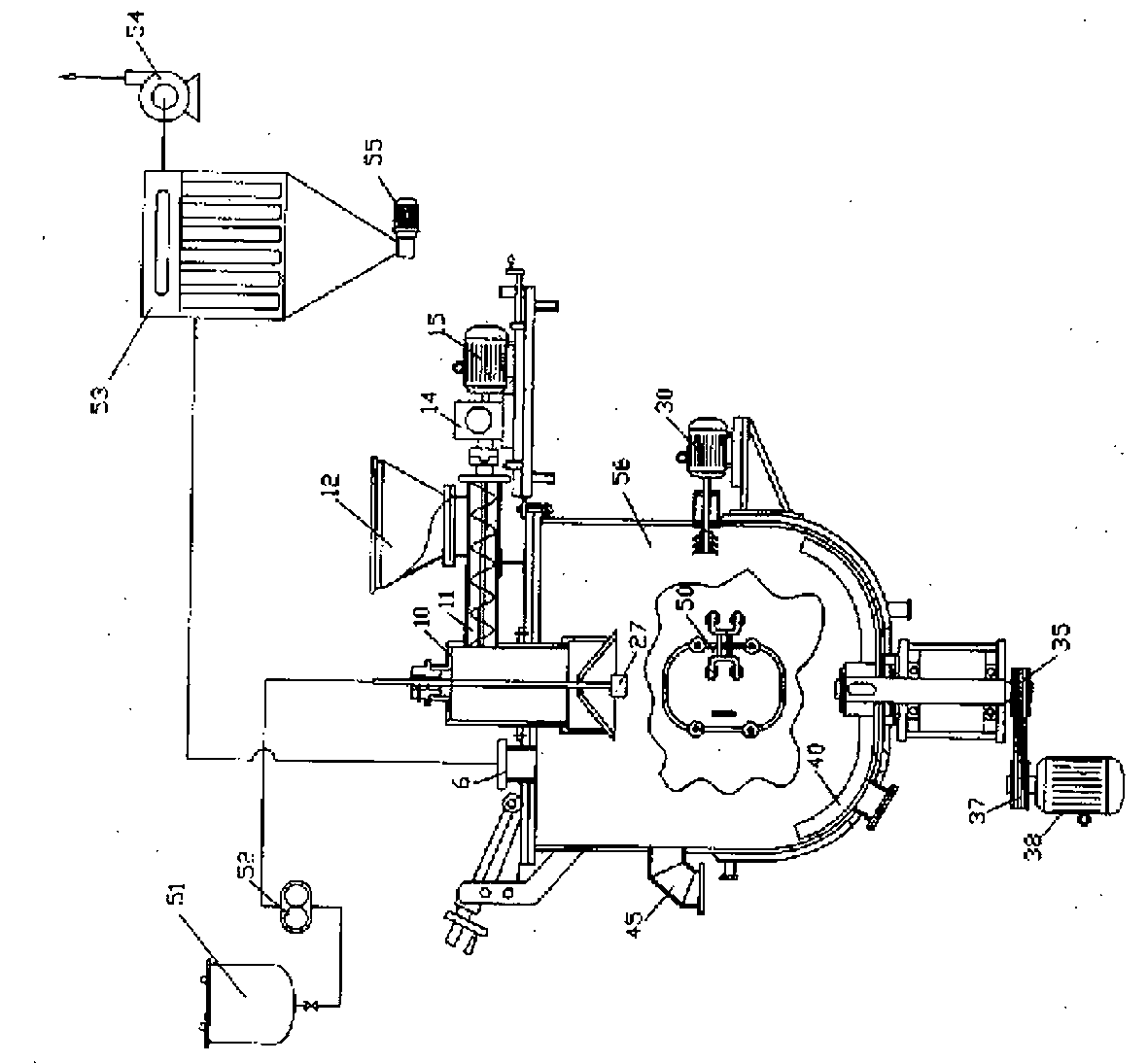

[0019] A continuous stirring granulator, including a liquid tank 51, a pressurized pump 52, a bag filter 53, an induced draft fan 54, a feeding hopper 12, a screw feeder 11, a granulation chamber 56, an exhaust pipe 6, and a feeding circle Barrel 10, powder distribution cone 26, atomizer 27, stirring paddle 40, crushing flying knife group 28. The liquid tank 51 and the booster pump 52 with a pressure of 1.24Mpa and a flow rate of 1L / min are connected to the atomizer 27 through pipelines, and the bag filter 53 and the air volume are 70-100m 3 The induced draft fan 54 of / h is connected to the exhaust pipe 6 through the air duct, and a star valve 55 is installed under the bag filter 53 .

[0020] The granulation chamber 56 is a cylindrical body 1 with a bottom arc shape, a flange 22 at the upper end, a diameter of 0.6 m, and a height of 0.6 m. The flange 22 at the upper end of the cylindrical body 1 is provided with a loam cake 23, and the loam cake 23 is connected with flange ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap