Arc groove milling cutter

A technology of arc grooves and milling cutters, which is applied to milling cutters, milling machine equipment, milling machine equipment details, etc., can solve the problems that affect the machining accuracy, low work efficiency, and easy to produce errors, and achieve the effect of high machining accuracy

Inactive Publication Date: 2012-12-26

WUXI YUTIAN PRECISION TOOL

View PDF0 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] In the prior art, when machining arc grooves, it is first necessary to use a slot milling cutter to mill a rectangular groove on the surface of the workpiece, and then use a ball end mill to further process the rectangular groove into an arc-shaped groove. During the processing, it is necessary to replace the In this way, not only is it time-consuming and laborious, but the work efficiency is low, and due to the need to re-set the tool, errors are prone to occur, which affects the machining accuracy

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

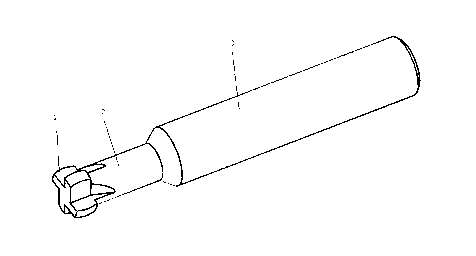

[0009] Such as figure 1 Shown:

[0010] The arc groove milling cutter of this embodiment is composed of an integrally formed cutter head 1, neck 2 and handle 3, the handle 3 is a cylindrical straight handle, and the cutter head 1 is provided with four cutting edges, each The included angle between the cutting edges is 90 degrees, and the edge surface of the cutting edges is arc-shaped.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to an arc groove milling cutter, comprising a cutter head, a neck and a handle, wherein the handle is straight, the cutter head is provided with four cutting edges, the included angle between adjacent cutting edges is 90 degrees, and the active face of the cutting edge is arc-shaped. According to the invention, the active face of the cutting edge is arc-shaped, thus integral molding can be realized when an arc groove is processed, the processing accuracy is high, and labor saving and time saving are achieved.

Description

technical field [0001] The invention relates to a milling cutter, in particular to an arc groove milling cutter. Background technique [0002] In the prior art, when machining arc grooves, it is first necessary to use a slot milling cutter to mill a rectangular groove on the surface of the workpiece, and then use a ball end mill to further process the rectangular groove into an arc-shaped groove. During the processing, it is necessary to replace the In this way, it is not only time-consuming and labor-intensive, but the work efficiency is low, and due to the need to re-set the tool, errors are prone to occur, thereby affecting the machining accuracy. Contents of the invention [0003] In order to overcome the above defects, the present invention provides an arc groove milling cutter with high processing efficiency and high precision. [0004] To achieve the above object, the technical solution of the present invention is: [0005] An arc groove milling cutter is composed...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B23C5/10B23C3/34

Inventor 朱胜雷

Owner WUXI YUTIAN PRECISION TOOL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com