Vehicle with fuel filler line and rear compound crank arrangement

A technology combining tie rod shafts and injection pipes, applied in the direction of the arrangement combined with the fuel supply of internal combustion engines, power plants, vehicle components, etc., to achieve the effect of simple extension routes and compact structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

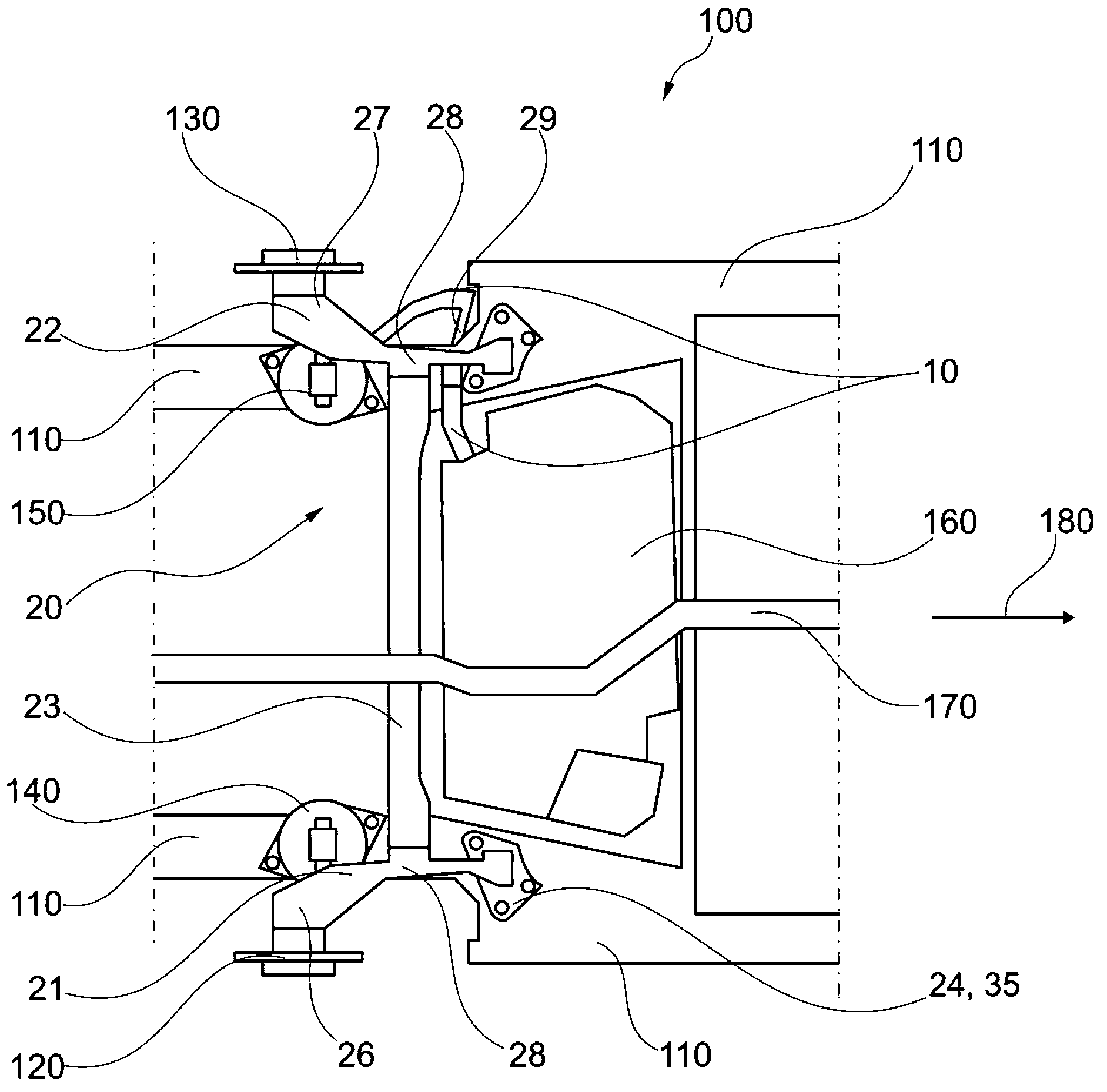

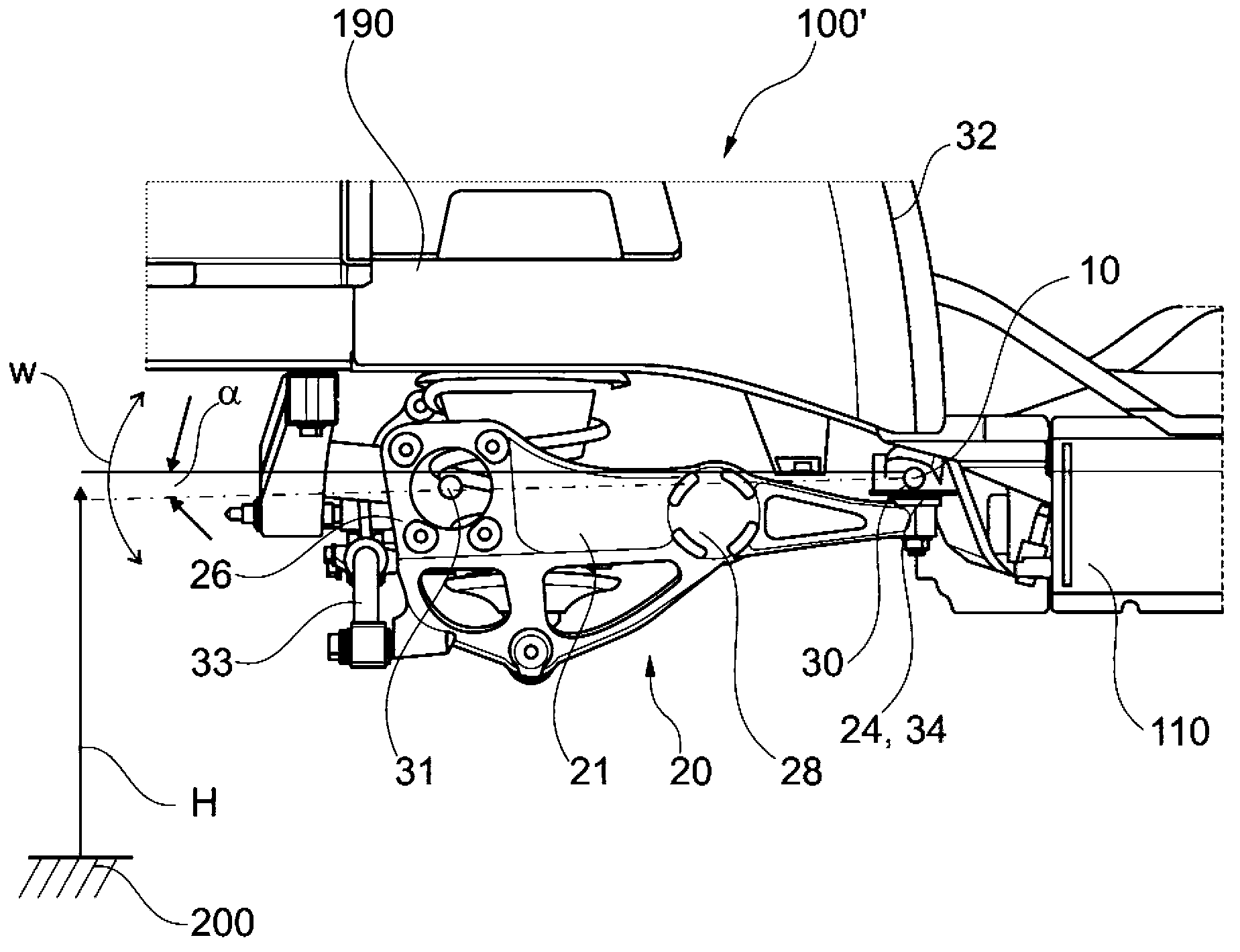

[0035] figure 1 A partial bottom view of a possible embodiment of the rear part 100 of a vehicle in the area of the combined tie rod shaft 20 of the rear part 100 is shown.

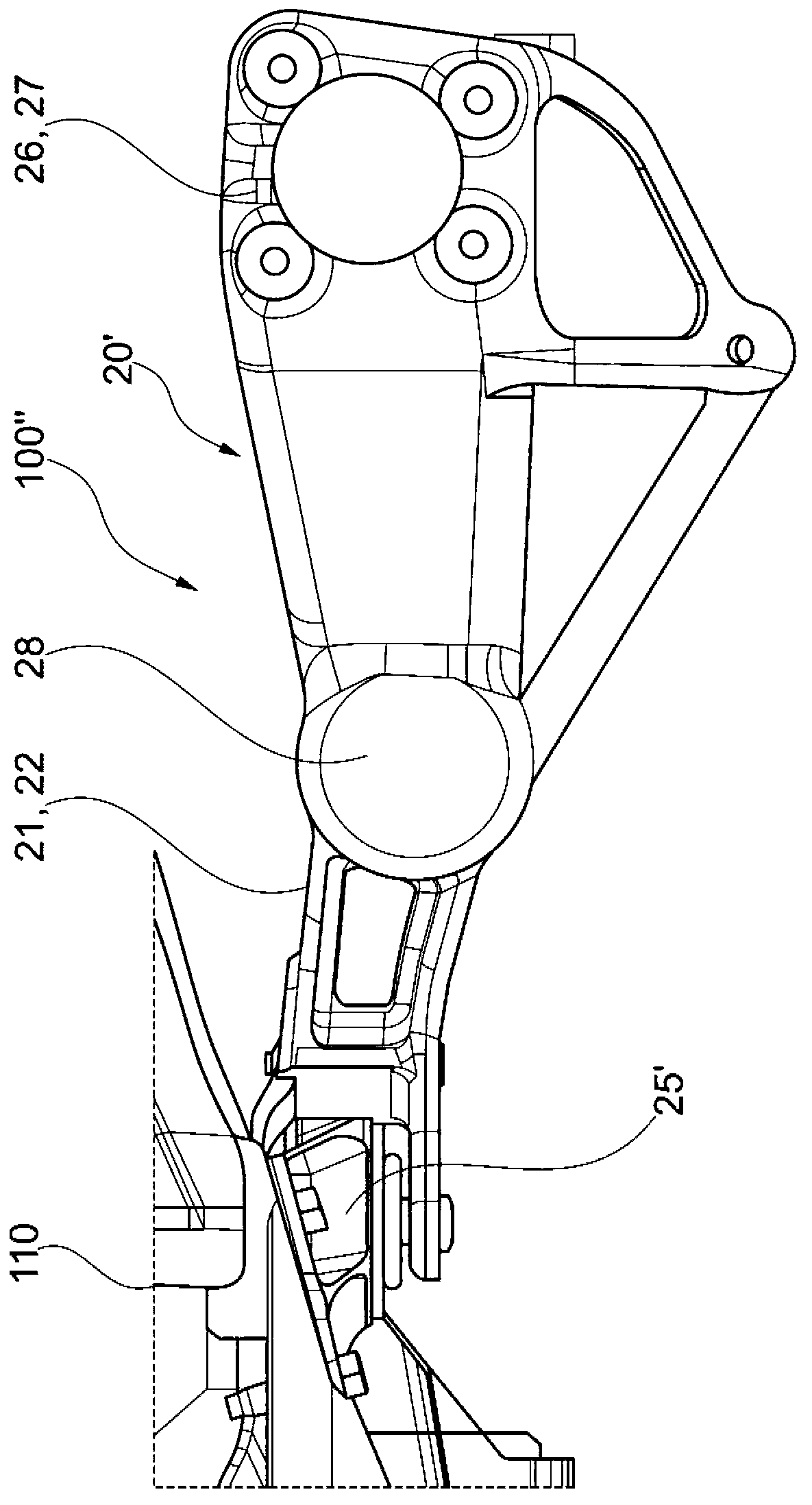

[0036] The rear part 100 has a body structure 110, and the combined tie rod shaft 20 is rotatably supported on the body structure 110, especially in a vertical direction of the rear part 100. To this end, the combined tie rod shaft 20 has connecting elements 24, 25, and the combined tie rod shaft 20 is connected to the vehicle body 110 by means of the connecting elements 24, 25. The connecting elements 24, 25 are, for example, so-called bushes, in particular A bushes.

[0037] The connecting elements 24, 25 are arranged on the two longitudinal rods 21, 22 of the combined rod shaft 20, wherein the connecting element 24 is assigned to the longitudinal rod 21 and the connecting element 25 is assigned to the longitudinal rod 22. The connecting elements 24, 25 are preferably arranged at the ends of the longitudi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com