Concrete composite slab floorslab with shear key and prefabricated construction and construction method

A technology of shear key and concrete, which is applied in the direction of floors, building structures, building components, etc., can solve the problems of increasing the amount of steel bars, high project cost, and floor thickness, etc., and achieve the effect of reducing the thickness of the plates and the amount of steel bars

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

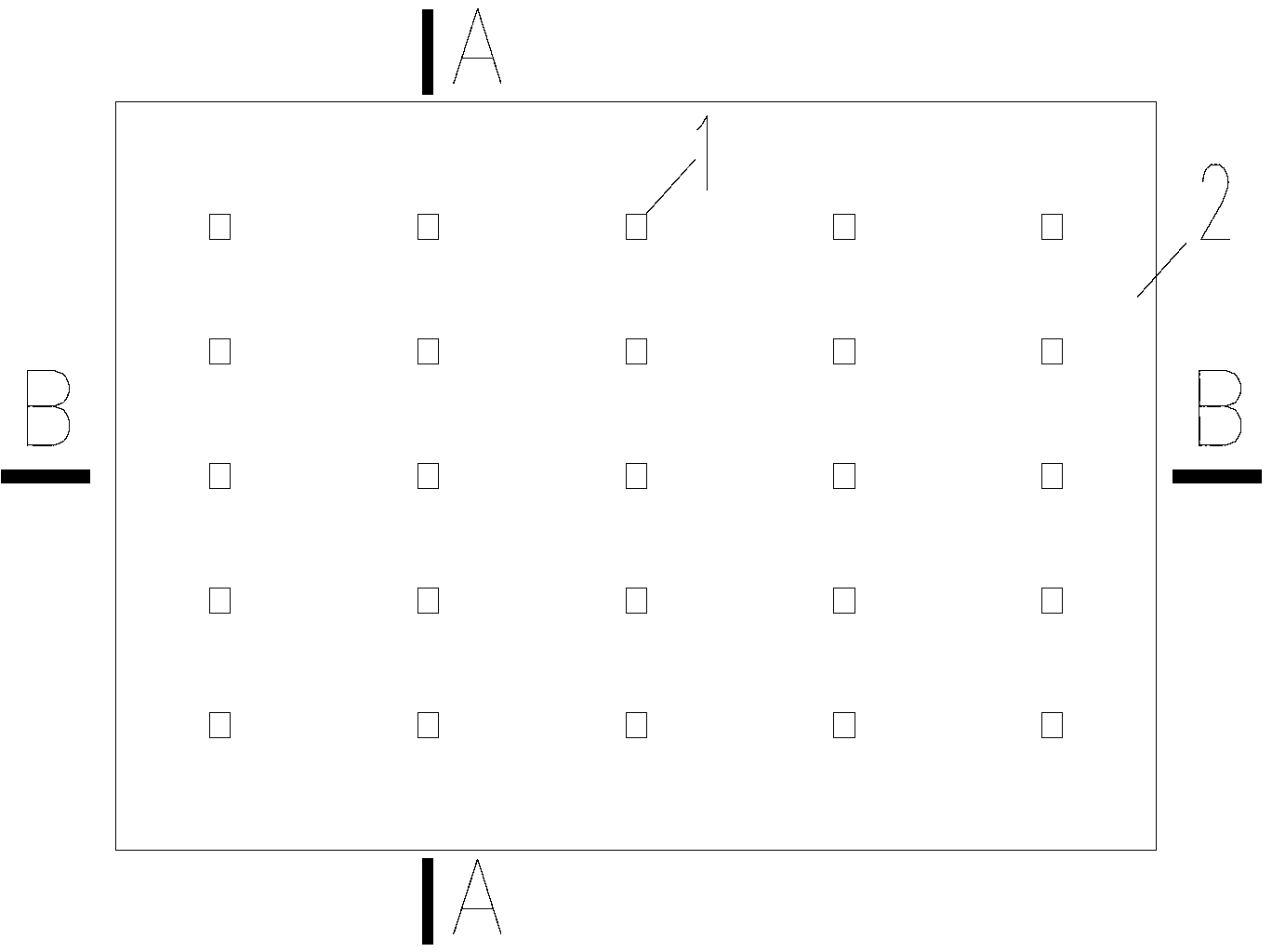

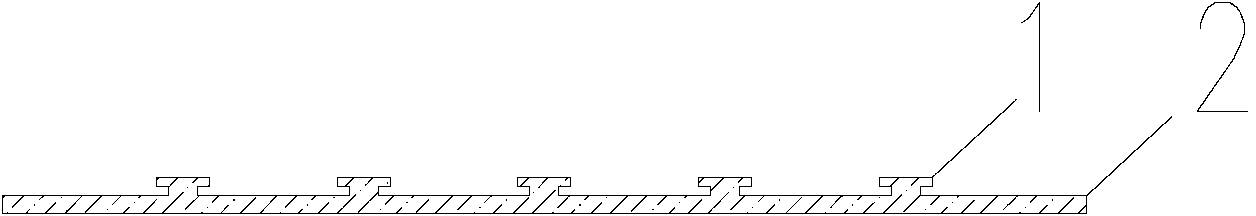

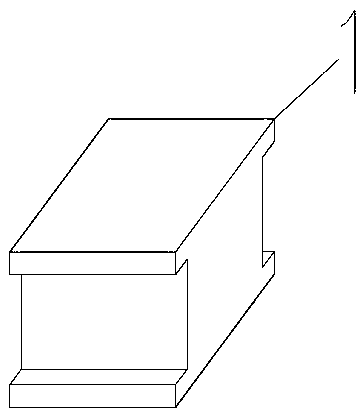

[0034] Such as Figure 1-4 As shown, the present invention is provided with shear keys 1 on the prefabricated bottom plate 2 , and the shear keys 1 are evenly distributed on the prefabricated bottom plate 2 according to the shear force and tensile force that the shear keys 1 need to bear. Among them, the section design of the shear key 1 is I-shaped ( Figure 2-4 ); Alternatively, the shear bond 1 may be in the shape of a ring, a hexagon or other shapes.

[0035] Such as Figure 5-7 As shown, the concrete composite slab floor slab with shear key of the present invention mainly includes the cast-in-place layer 3 and the prefabricated base plate 2 arranged up and down, the prefabricated base plate 2 is provided with the shear key 1, and the prefabricated base plate 2 is connected to the existing base plate through the shear key 1. The pouring layers 3 are connected to form a firm bonded structure. One end of the shear key 1 is buried in the prefabricated bottom plate, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com