Open-web floor system steel net cage mould box construction method

A hollow floor and construction method technology, which is applied in the fields of architecture, building structure, and building materials, can solve the problems of not being able to effectively suppress the generation of floor microcracks, not being able to guarantee the appearance quality of the bottom, and not being able to directly observe the dense state , to achieve the effect of reducing construction cost, reducing construction difficulty and convenient laying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

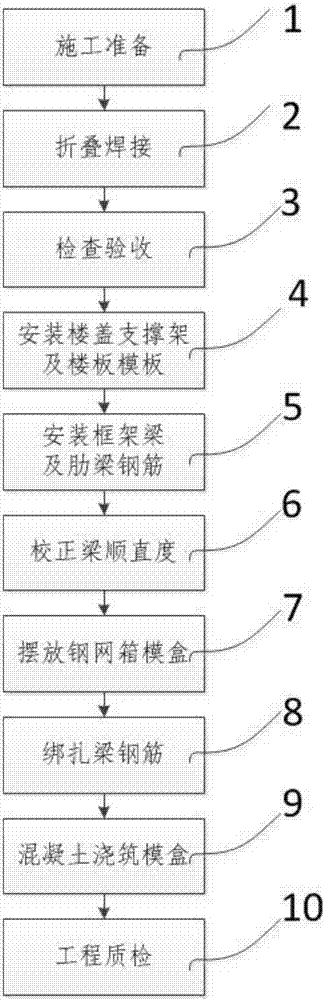

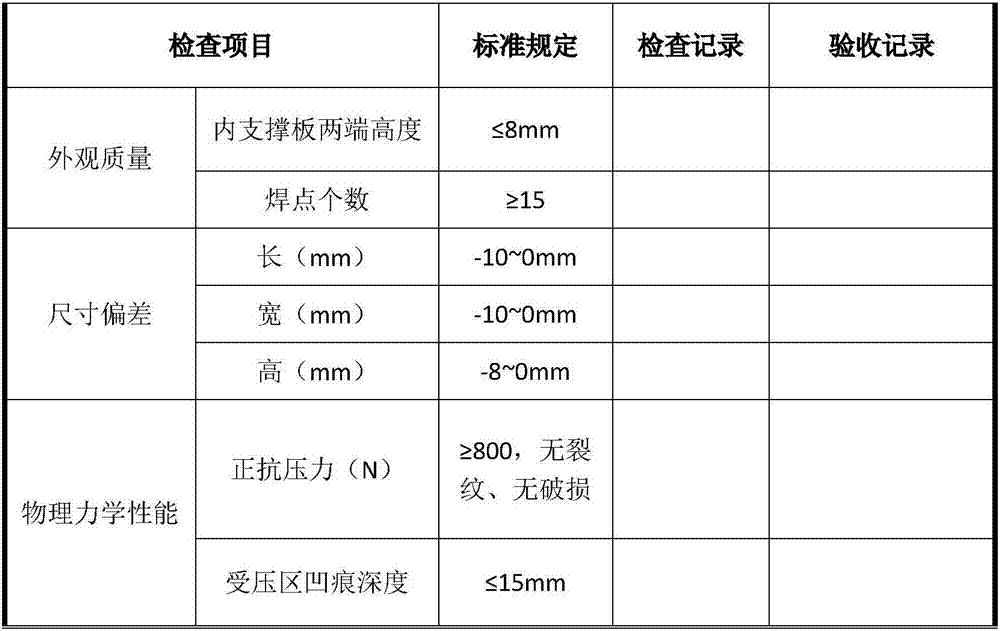

Method used

Image

Examples

Embodiment 1

[0048] Guiyang National High-tech Zone Digital Publishing and Printing Industry Project Second Bid Project, structural form: the foundation is hole pile plus independent column foundation, the main body is frame structure, the roof is grid structure, the floor plate is hollow plate structure, the original design adopts GBF honeycomb core The mold box was later changed to a steel cage mold box.

[0049]Construction scale: The total construction area of this project is: 163539.40M2, which is a group project. It includes: Building No. 1 (general book sorting workshop): construction area of 23959.20M2, building height: 23.90m, number of building floors: 4 floors above ground; Building No. 2 (textbook and teaching auxiliary sorting workshop 1): construction area 27951.00M2, building height: 14.10m, number of building floors: 2 floors above ground; Building No. 3 (Teaching materials, teaching aids sorting workshop 2): building area 20901.00M2, building height: 14.10m, number of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Carrying capacity | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com