Post-tensioned prestressed prefabricated type concrete composite beam reinforcing steel bar structure and design method thereof

A post-tensioning prestressing and prestressing tendon technology, applied in truss structures, structural elements, joists, etc., can solve the problems of low construction efficiency, poor seismic performance, complex structure, etc., to facilitate on-site installation and improve seismic performance. Performance, concrete damage reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

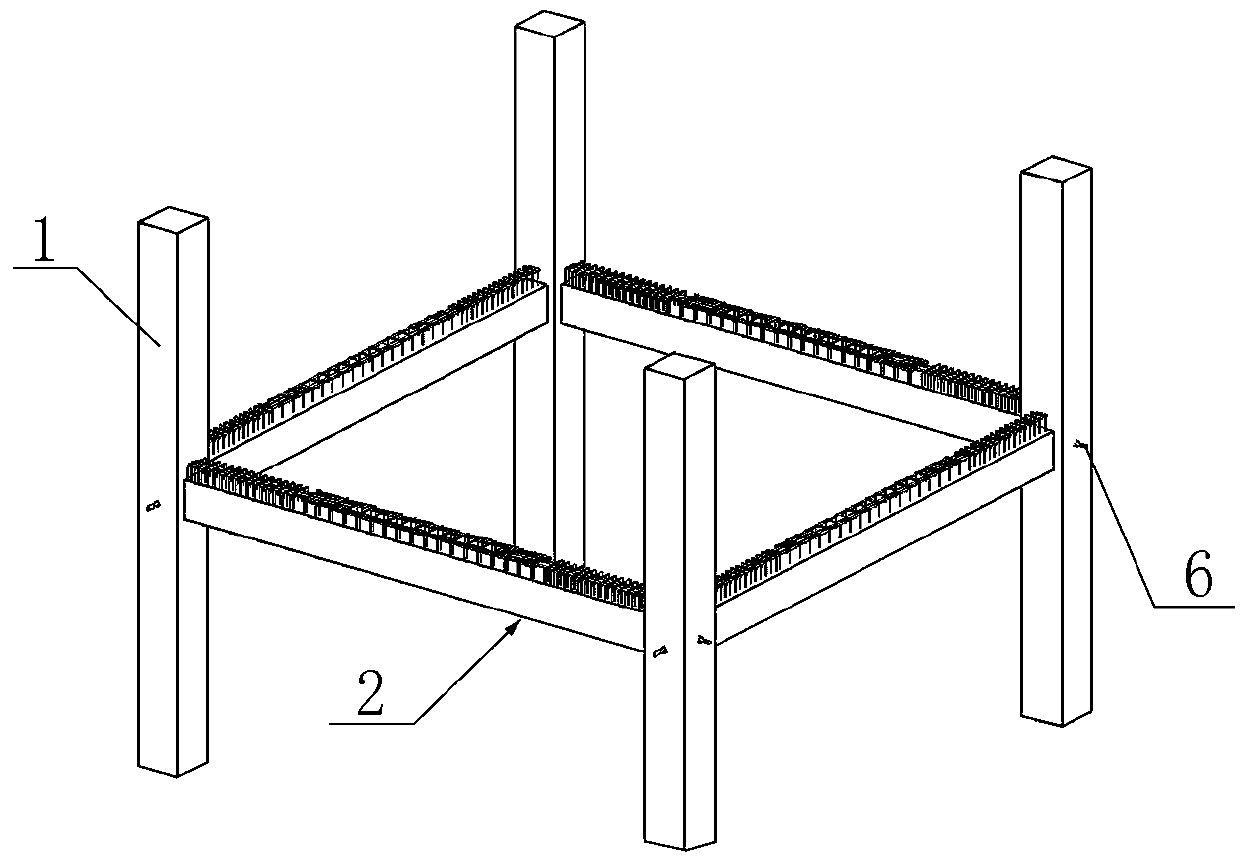

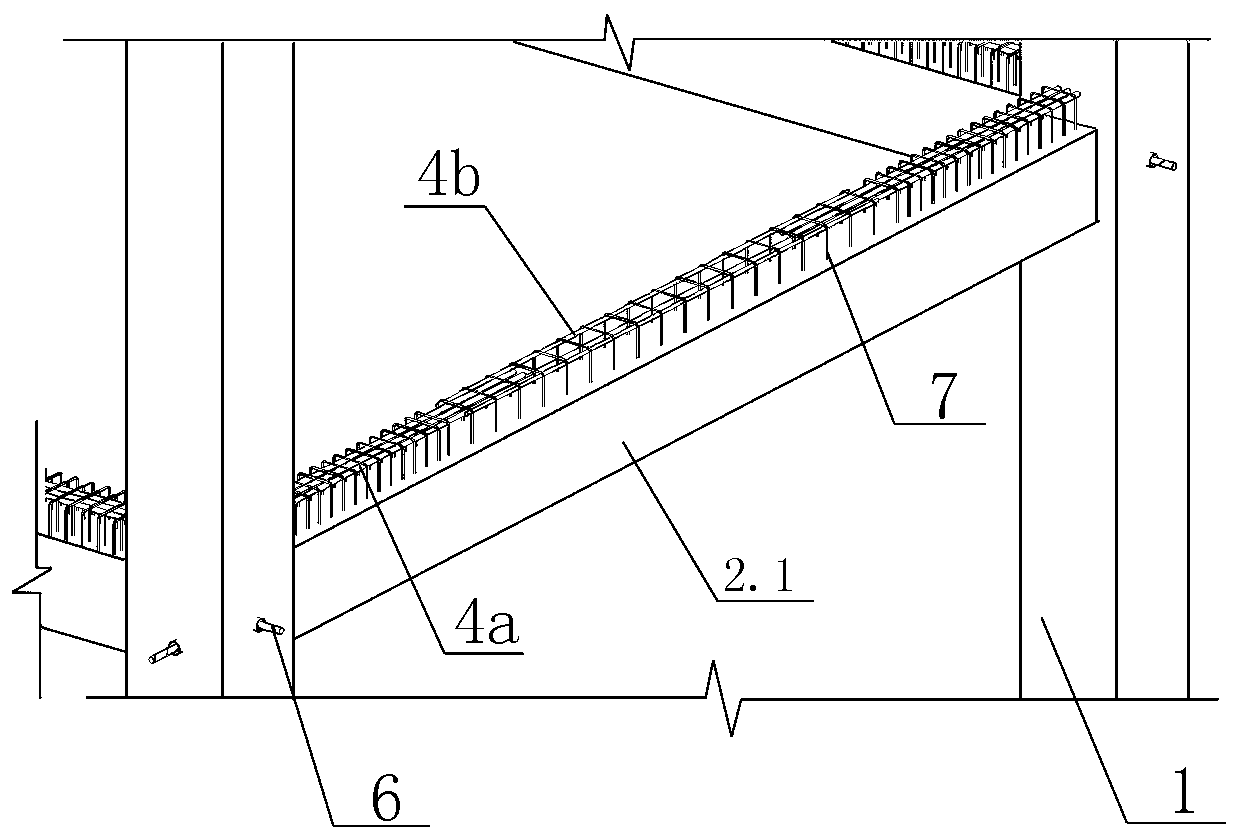

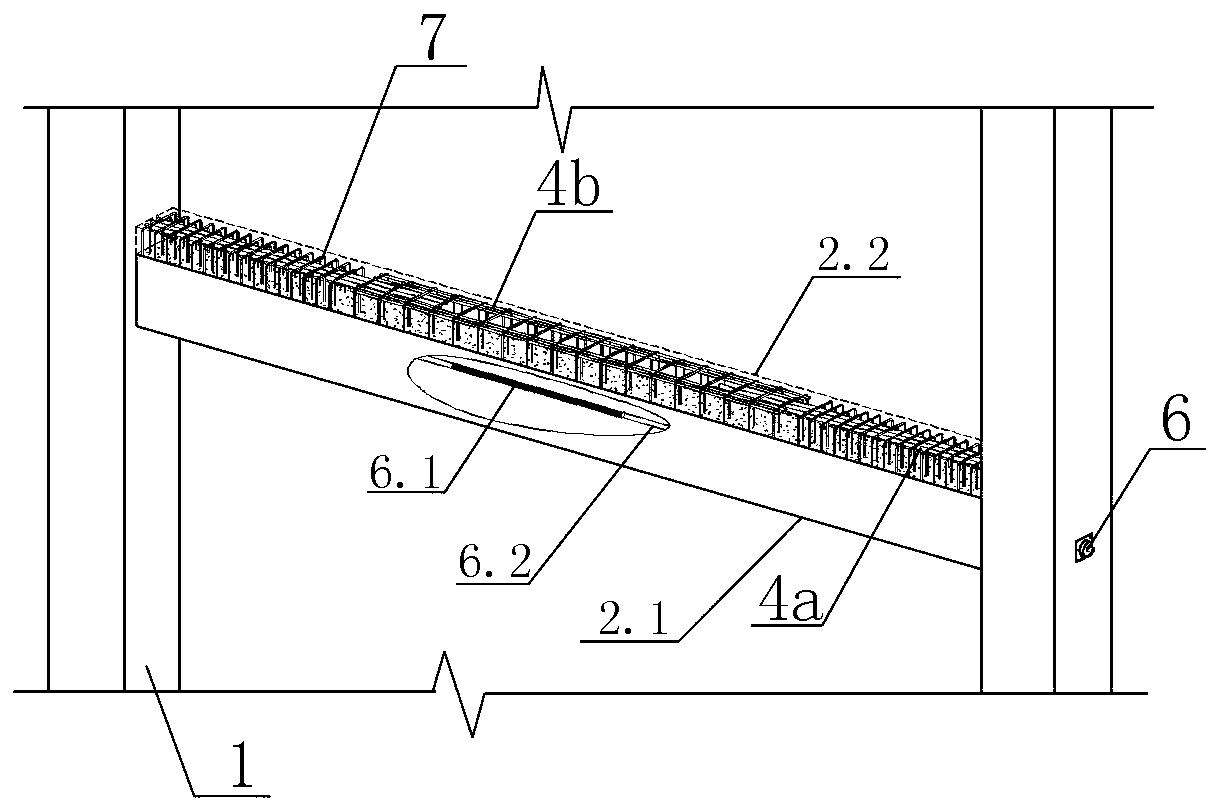

[0044] Such as Figure 1-12 As shown, this post-tensioned prestressed assembled concrete composite beam reinforcement structure includes beam lower reinforcement, waist bar 5, beam upper reinforcement, stirrup 7 and prestressed tendons 6; The bottom of the prefabricated layer 2.1 of the beam 2, and the lower reinforcement of the beam includes the lower structural reinforcement 3a of the beam; the lower structural reinforcement 3a of the beam is distributed on both sides of the cross section of the prefabricated layer 2.1, and at least two are respectively arranged on each side; The lower structural steel bars 3a are arranged along the longitudinal length of the prefabricated layer 2.1; the waist bars 5 have two groups, which are respectively arranged on the left and right sides of the precast layer 2.1; wherein, each group of waist bars 5 is arranged vertically at intervals; the upper part of the beam The steel bars are located on the top of the post-cast laminated layer 2.2 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com