Automatic microfluid sample introduction device capable of realizing unpowered sequential sample introduction and application thereof

An automatic sampling and microfluidic technology, applied in the direction of analyzing materials, instruments, etc., can solve the problems of large size, complicated operation, complicated design, etc., and achieve the effect of small size, small dead volume, and easy production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

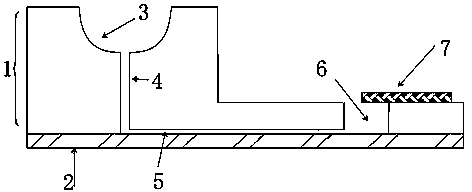

[0022] Example 1 A microfluidic automatic sampling device for unpowered sequential sampling

[0023] see figure 1 , the device of the present invention is composed of a microfluidic layer 1 and a bottom cover sheet layer 2, a U-shaped liquid storage tank 3, a sample injection channel 4, a microfluidic channel 5, a sample outlet 6, and a waste liquid removal module 7. The sample outlet 6 By being a cylindrical notch, the microfluidic channel 5 is connected to the sample inlet channel 4 and the sample outlet 6, the waste liquid removal module 7 is covered on the sample outlet 6, and its front edge is in the middle of the sample outlet 6, and the microfluidic Layer 1 and bottom cover sheet layer 2 are sealed together, and the microfluidic layer 1 contains at least one of the above-described sampling units.

[0024] The materials of the waste liquid removal module 6 are sponge and filter paper.

[0025] The curvature of the bottom of the U-shaped liquid storage tank should be ge...

Embodiment 2

[0029] Example 2 Using the device of the present invention

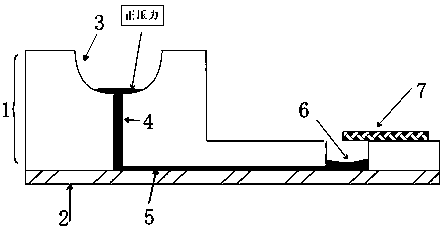

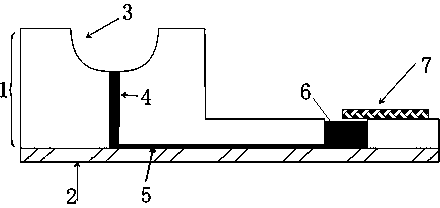

[0030] see figure 1 , a single-channel injection example

[0031] The bottom cover sheet layer 2 is a glass surface coated with a nano-gold film, and the gold film is a smooth surface without any modification on the surface. The microfluidic layer 1 is sealed with the nano-gold film layer by means of surface plasma treatment, solid glue bonding, etc. If the microfluidic layer 1 is a flexible polymer, gently squeeze the microfluidic layer 1 Sealing is also possible. The signal after the sample solution enters the microfluidic channel 5 is recorded by the surface plasmon resonance device.

[0032] The first step is to fill the bottom of the U-shaped liquid storage tank 3, the sample injection channel 4, the microfluidic channel 5, and the bottom of the sample outlet 6 with buffer. The process is as follows: figure 2 shown. An appropriate amount of buffer is placed in the U-shaped liquid storage tank 3, and a posi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com