Quality information management system for machine tool

A management system and quality information technology, applied in manufacturing computing systems, general control systems, control/regulation systems, etc., can solve the problems of time consumption and human resources, scattered static information, and difficult to trace, to improve the quality of operators, The effect of improving work efficiency and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

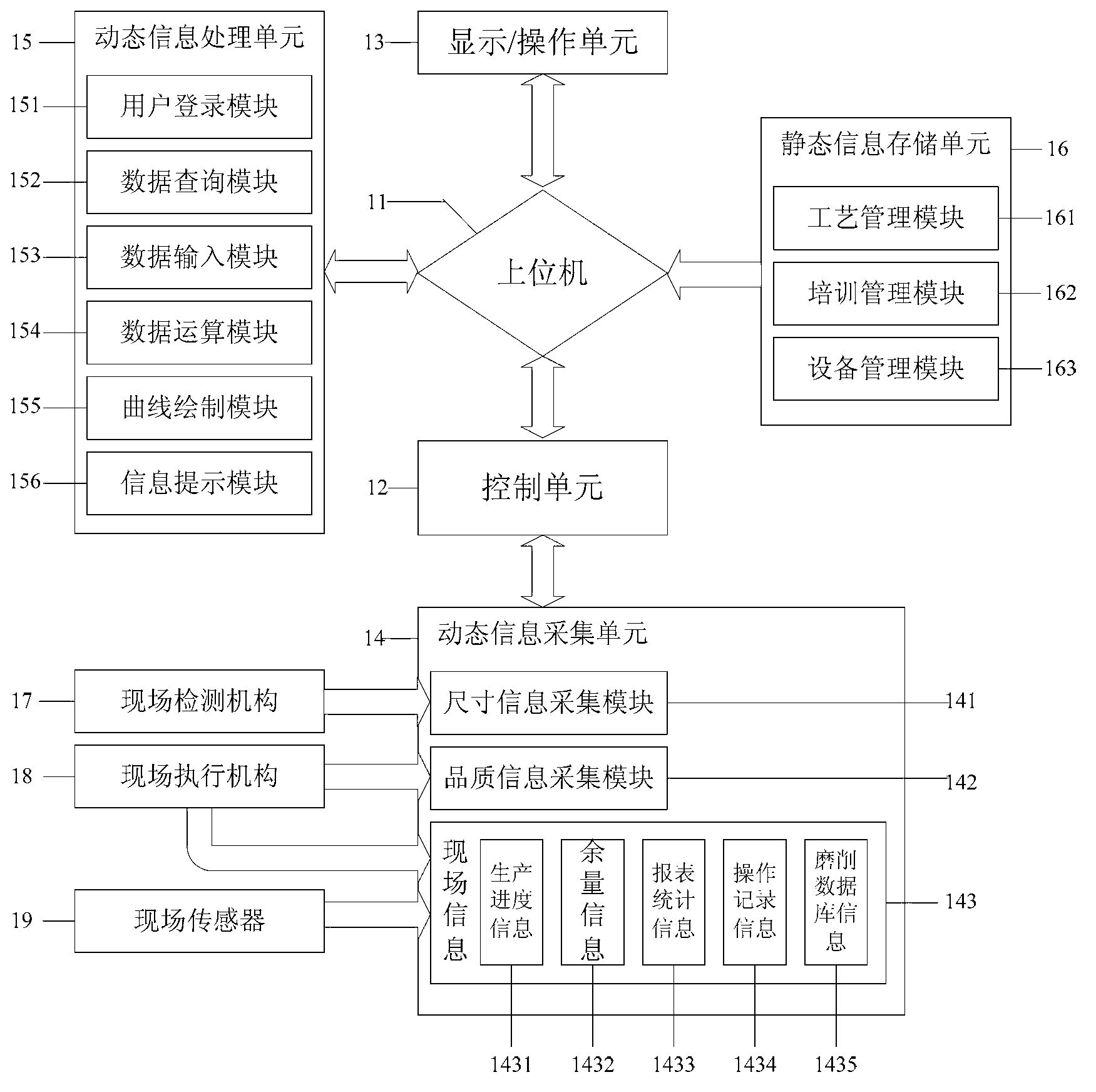

[0092] Specific embodiments of the present invention will be described below in conjunction with the accompanying drawings. refer to figure 1 .

[0093] A machine tool quality information management system, comprising a host computer 11, a control unit 12, a dynamic information processing unit, a static information processing unit, a dynamic information acquisition unit 14, and a display / operation unit 13; the host computer 11 is connected to the control unit 12 by communication The upper computer 11 is connected with the dynamic information processing unit in communication; the upper computer 11 is connected with the static information processing unit in communication; the upper computer 11 is connected with the display / operation unit 13 in communication; the control unit 12 is connected with the dynamic information collection The unit 14 is connected by communication; the dynamic information collection unit 14 collects the data information of the on-site inspection mechanis...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap