Method for making an anode body of an electrolytic capacitor

A technology of electrolytic capacitors and anode bodies, which is applied in the direction of capacitor electrodes and capacitor parts, etc., can solve the problems of electrolytic capacitor performance, life, leakage current and other problems, so as to improve the capacity extraction rate, improve product performance, and reduce production energy consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

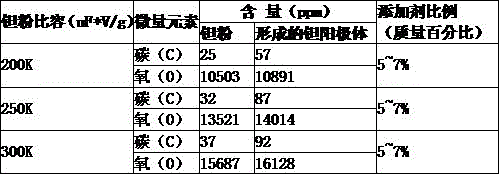

[0016] Add additives paraffin and gasoline to tantalum powder, then mix, and then press the mixture to make tantalum anode blocks; the use of additives and gasoline can make tantalum powder form pseudo-spherical particles and improve the fluidity of tantalum powder , which is convenient for tantalum powder to form a tantalum anode block. Among them, the specific volume of tantalum powder is 200-300KμF·V / g.

[0017] Under the condition of a temperature of 40°, immerse the tantalum anode block in alcohol for 10 minutes to fully dissolve the paraffin and gasoline in the tantalum anode block into the alcohol.

[0018] Take out the tantalum anode block, and wash the tantalum anode block with water for 5 minutes at a temperature of 40°, so that the residual alcohol, paraffin and gasoline in the tantalum anode block are fully dissolved in water. At a temperature above 40°, These ingredients are highly soluble in water.

[0019] The block of tantalum anode body is sintered to form t...

Embodiment 2

[0021] Add additives stearic acid and trichloroethane to tantalum powder, then mix, and then press the mixture to make a tantalum anode block; the use of additives and trichloroethane can make the tantalum powder form a pseudo-spherical Particles improve the fluidity of tantalum powder and facilitate the formation of tantalum anode blocks by tantalum powder.

[0022] Under the condition of a temperature of 70°, immerse the tantalum anode block in alcohol for 20 minutes to fully dissolve the stearic acid and trichloroethane in the tantalum anode block into the alcohol.

[0023] The tantalum anode block was taken out, and the tantalum anode block was washed with water for 7 minutes at a temperature of 60°, so that the residual alcohol, stearic acid and trichloroethane in the tantalum anode block were fully dissolved in the water.

[0024] The block of tantalum anode body is sintered to form the anode body. The carbon content of the produced tantalum anode body is reduced to 30-...

Embodiment 3

[0026] Add additives camphor and alcohol to niobium oxide powder, then mix, and then press the mixture to make a tantalum anode block; the use of additives and alcohol can make the tantalum powder form pseudo-spherical particles and improve the flow of the tantalum powder It is convenient for tantalum powder to form a tantalum anode block. Among them, the specific volume of niobium oxide is 200-300KμF·V / g.

[0027] Under the condition of a temperature of 100°, the tantalum anode block is immersed in acetone for 30 minutes, so that the camphor and alcohol in the tantalum anode block are fully dissolved in the acetone.

[0028] The tantalum anode block is taken out, and the tantalum anode block is washed with water for 10 minutes at a temperature of 90°, so that the remaining acetone, camphor and alcohol in the tantalum anode block are fully dissolved in the water.

[0029] The block of tantalum anode body is sintered to form the anode body. The carbon content of the produced ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap