Manufacture method of semiconductor device

A manufacturing method and semiconductor technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electric solid-state devices, etc., can solve problems such as indeterminacy, and achieve the effects of preventing the introduction of thermal strain, high reliability, and prolonging failure life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] The embodiments are explained in the following examples.

[0065]

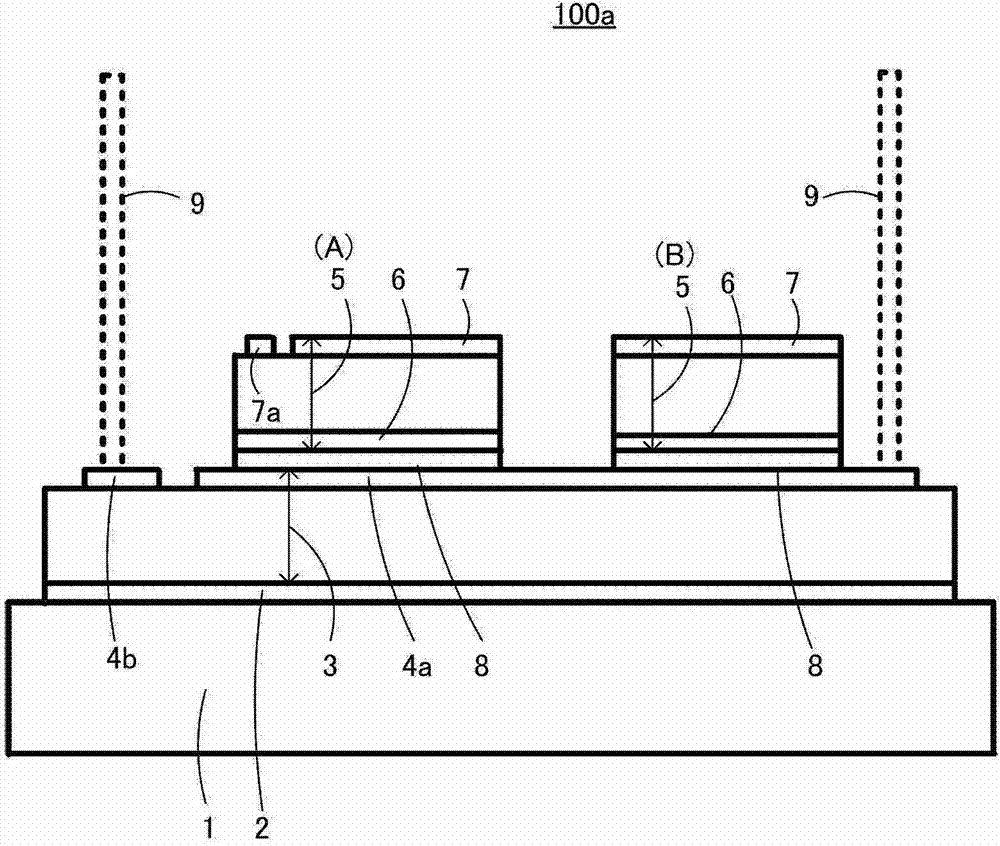

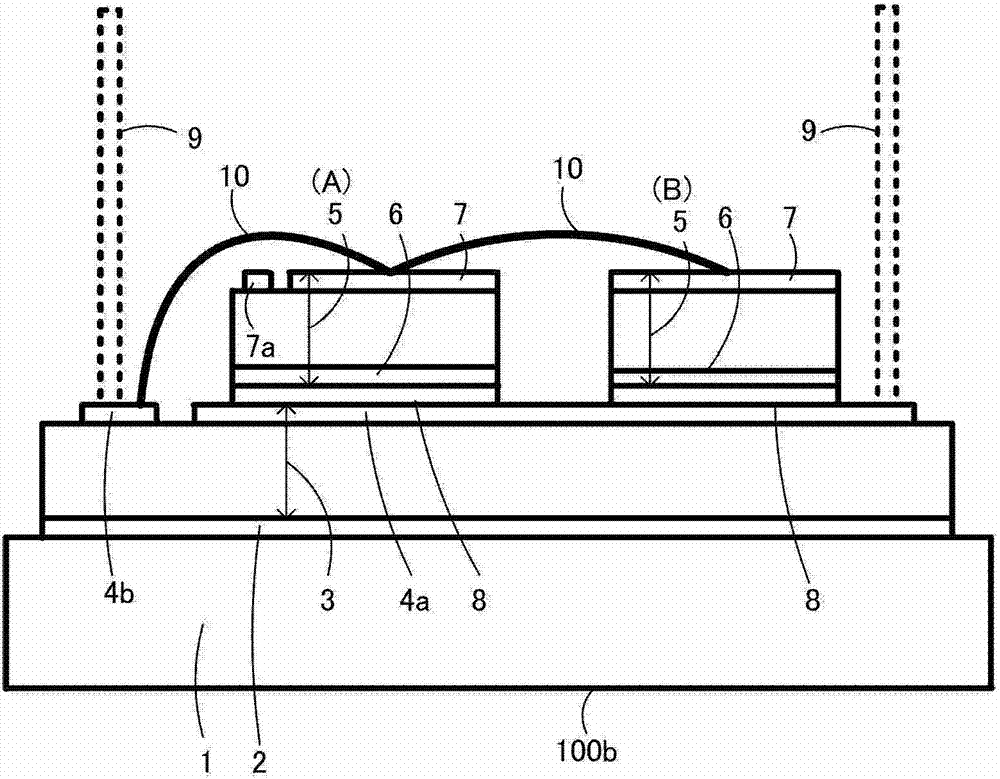

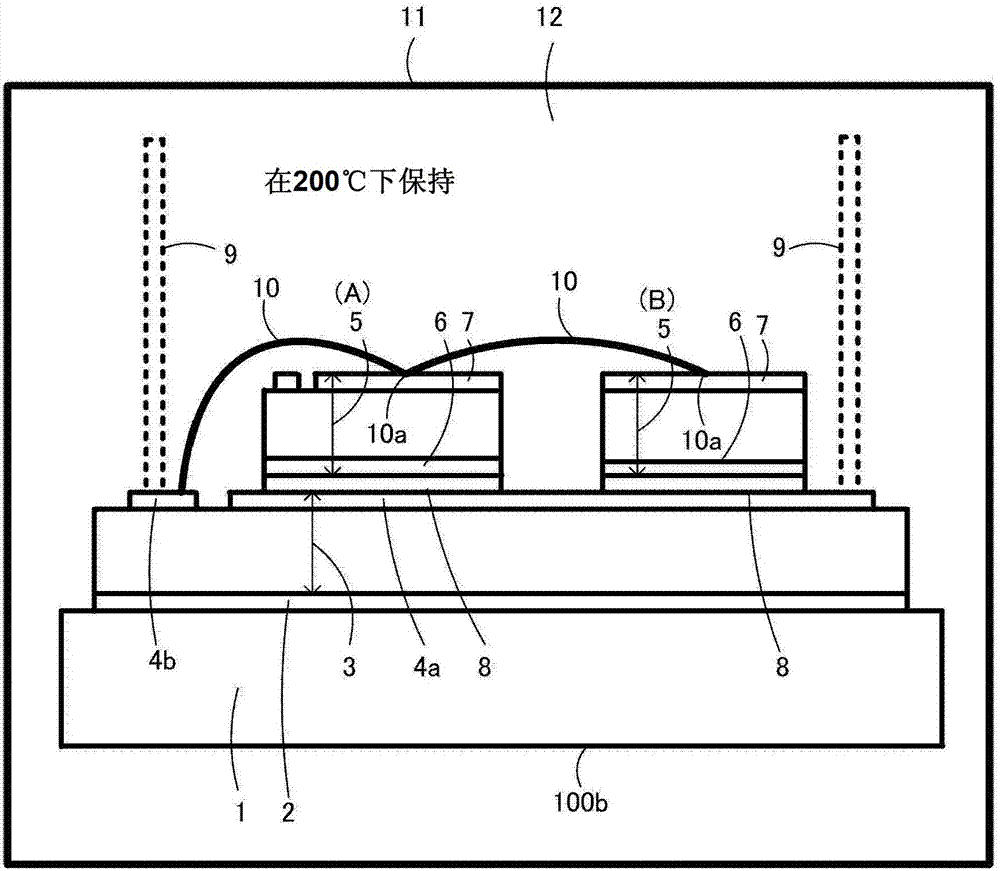

[0066] Figure 1 ~ Figure 6 This is a method of manufacturing a semiconductor device according to an embodiment of the present invention, and is a cross-sectional view of the main part of the manufacturing process shown in terms of process steps. The semiconductor device is, for example, a power module in which an IGBT chip and a diode are connected in anti-parallel.

[0067] First, like figure 1 As shown, the back electrode 6 of the semiconductor chip 5 is fixed with the bonding material 8 on the conductive pattern 4a of the conductive patterned insulating substrate 3 fixed on the heat dissipation base plate 1 by the bonding material 2. In addition, an external lead-out terminal 9 is fixed to the conductive pattern 4b. This member composed of the heat dissipation base plate 1, the insulating substrate 3 with a conductive pattern, the semiconductor chip 5, and the external lead-out terminal 9 is referred ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com