Method and equipment for using pulsed magnetic field to refine weld structure during welding

A technology of welding process and pulsed magnetic field, applied in welding equipment, arc welding equipment, welding accessories, etc., can solve the problems of unclear description of the working nature of the magnetic field, difficult to control the structure of the weld seam, complicated installation and arrangement of the excitation coil, etc. The forms and types of magnetic fields are rich, easy to realize and popularize, and the effect of reducing chemical inhomogeneity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

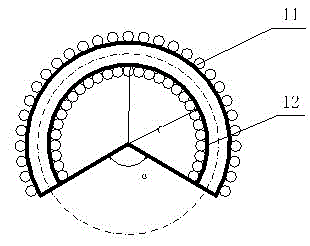

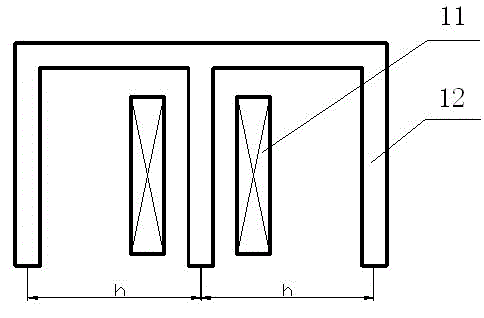

[0067]Al-6.5%Cu aluminum-copper alloy was used as the simulated weld material, which was heated to 750°C and then poured into a steel back cover mold preheated at 600°C to simulate the solidification of the weld metal in the V-groove with backing plate. In the case of other conditions being the same, the weld solidification structure obtained with or without the action of the magnetic field was compared to determine the effect of the pulsed magnetic field on the weld microstructure refinement. The main dimensions of the steel mold are shown in Figure 8. The length of the weld is 70 mm, the width of the opening is 30 mm, and the width of the bottom is 10 mm. The C-type or E-type coil is pressed on the steel mold. In the case of a magnetic field, the magnetic force line of the magnetic field is perpendicular to the direction of the weld, and the simulated weld material is solidified under the action of the pulsed magnetic field. The magnetic field parameters are: pulse voltage 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com