A pretensioned prestressed goose-shaped slab mold

A pre-stressing and pre-tensioning technology, applied in the direction of molds, etc., can solve the problems of high amortization cost of prefabrication plants, poor production balance of components, and large workload of pedestal construction, so as to reduce amortization costs, use high efficiency, expand The effect of market coverage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

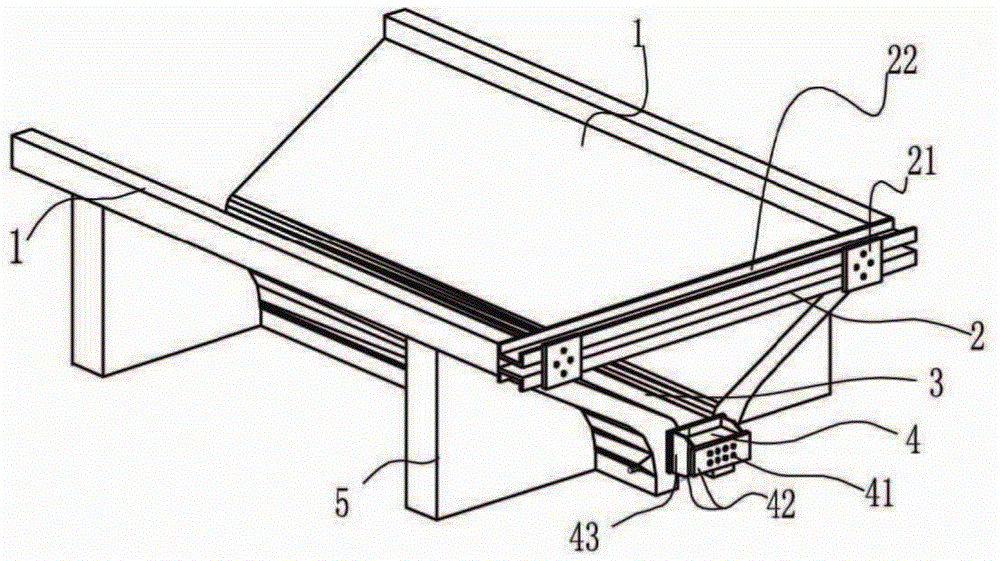

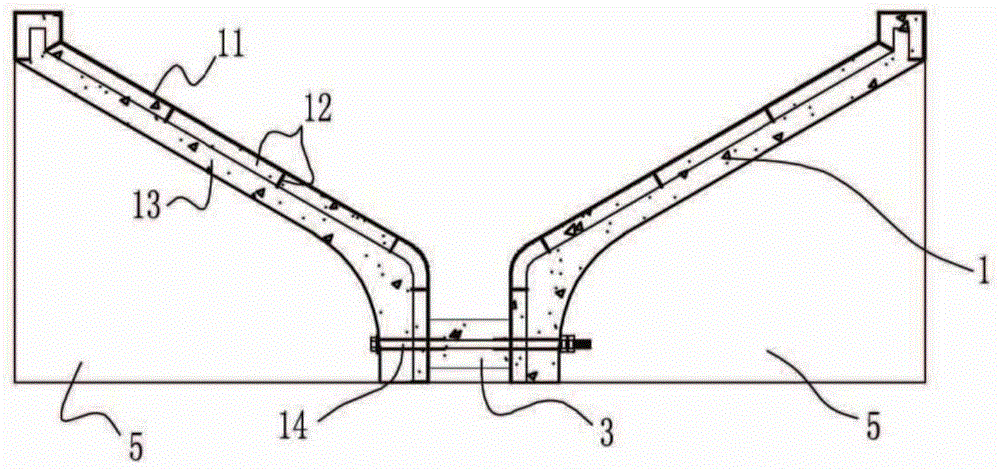

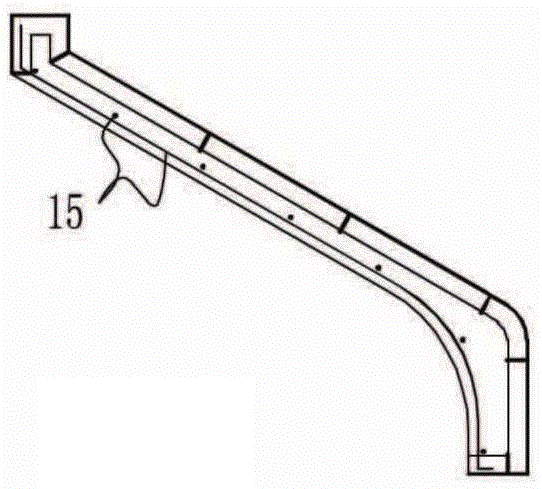

[0019] see Figure 1 to Figure 6 , The present invention provides an embodiment of a pre-tensioned prestressed geese plate mold, including a side form 1, a bottom form 3, and an end prestressed anchor beam 2 and an anchor plate 4. The side form 1 is formed by longitudinal splicing of several block-shaped special-shaped side forms, the special-shaped side form is a composite plate of steel plate and concrete, and the bottom form 3 is formed by longitudinally segmented splicing of several rectangular reinforced concrete beams. The present invention is used to manufacture the pre-tensioned prestressed geese-shaped slab by the long-line method, and the side mold 1 and the bottom mold 3 in the geese-shaped slab mold are both used as the bottom mold 3 of the prefabricated geese-shaped slab and as the tensioning part of the prestressed steel strand. For the top column, due to the long length of the overall formwork, the side form 1 and the bottom form 3 are assembled in sections for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com