An ocean-going ro-ro heavy-lift ship

An ocean-going and gondola technology, applied in the directions of ship accessories, transportation and packaging, cargo handling equipment, etc., can solve the problems of lack of large-scale equipment handling capacity and experience, restricting the development and expansion of energy enterprises, and restricting the production capacity of enterprises, so as to expand the market. Coverage, reasonable force, and the effect of reducing size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

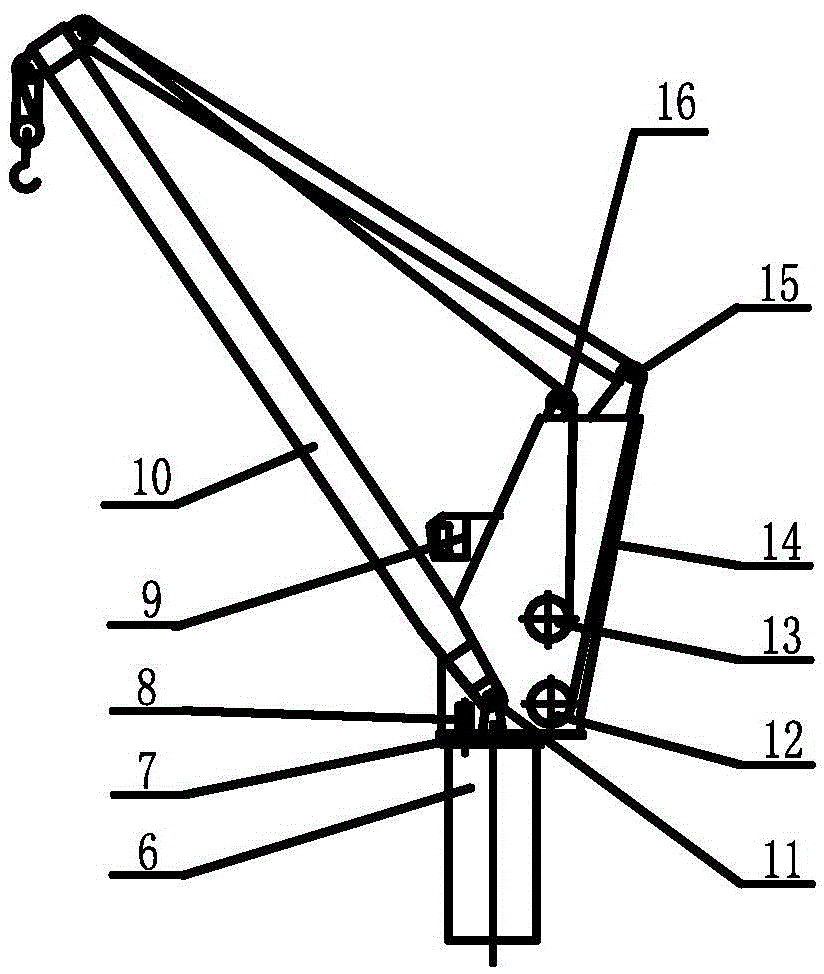

[0033] Below in conjunction with embodiment the present invention is described in further detail:

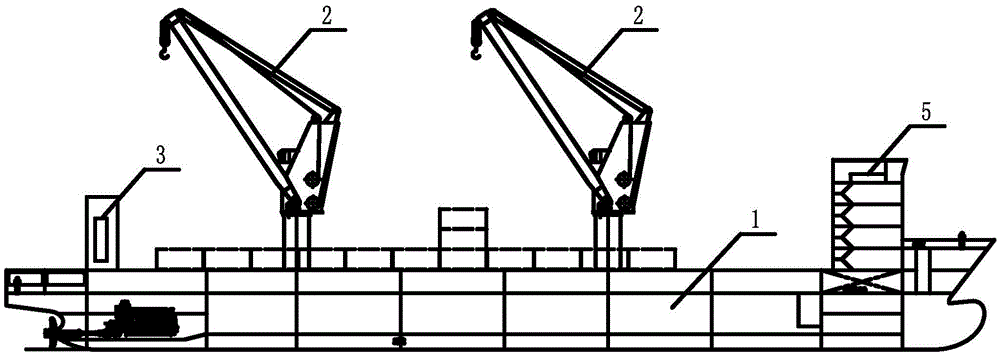

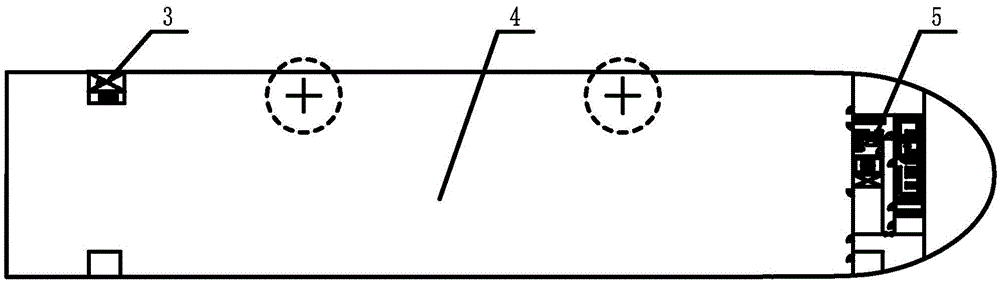

[0034] Such as figure 1 , 2 As shown, the heavy-lift ship of the present embodiment is made up of hull (1) and crane (2);

[0035] The deck of the hull (1) is provided with an extra large barrier-free deck area (4), and the size of the barrier-free deck area (4) is close to the size of the limited deck area; In addition, there are no obstacles on both sides of the deck, the only obstacles are the crane (2) and the chimney (3), and they are arranged on one side to provide more space for rolling cargo from the stern or sideways; the hull (1) There are no hatches on the deck, and no cargo holds below the deck. Such a hull structure can give full play to the carrying capacity of heavy lift ships for large cargo.

[0036] The hull (1) adopts an optimized twin-engine and double-propeller design scheme to make the hull (1) have a shallow draft; and the hull (1) is ice-strengthened,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com