A backup emergency braking system for automobiles

A brake system, emergency technology, applied in the direction of vehicle components, brakes, brake components, etc., can solve the problems of road or vehicle damage, non-reusable, poor safety, etc., to prolong the service life, prevent breakage, and good braking effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

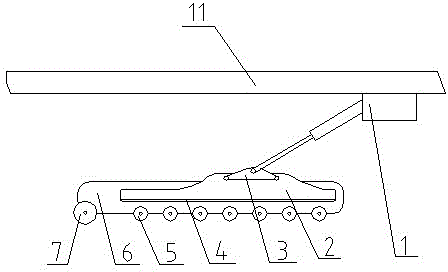

[0024] Such as figure 1 As shown, a spare emergency braking system for automobiles is mainly composed of an oil cylinder 1 and a brake box 6, the bottom of the brake box 6 is provided with a buffer roller 7 and multiple sets of brake rollers 5, the brake roller 5 and the buffer roller 7 They are all arranged perpendicular to the direction of travel, and the buffer roller 7 is arranged at the front end position of the bottom of the brake box 6, the brake box 6 is provided with a pressure seat 2, the bottom of the pressure seat 2 is provided with a friction plate 4, and the friction plate 4 There is a gap between it and the brake roller 5. There is a push block 3 on the top of the pressure seat 2. The upper end of the push block 3 is hinged to the piston rod of the oil cylinder 1 arranged at the bottom of the vehicle beam 11. The piston rod of the oil cylinder 1 is tilted towards the front of the vehicle. , and the angle formed by the piston rod and the vehicle beam 11 is 5-65°....

Embodiment 2

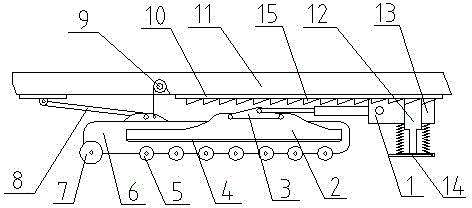

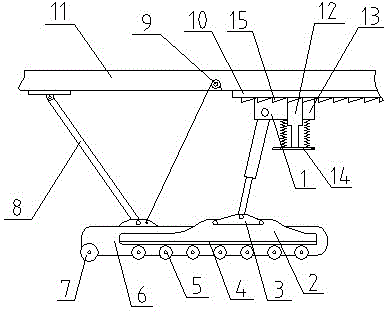

[0026] Such as figure 2 As shown, a spare emergency braking system for automobiles is mainly composed of an oil cylinder 1 and a brake box 6. The bottom of the brake box 6 is provided with a buffer roller 7 and multiple groups of brake rollers 5, and the buffer roller 7 is arranged on the brake At the front end position of the bottom of the casing 6, the brake casing 6 is provided with a pressure seat 2, and the bottom of the pressure seat 2 is provided with a friction plate 4, and there is a gap between the friction plate 4 and the brake roller 5, and the top of the pressure seat 2 A push block 3 is provided, the upper end of the push block 3 is hinged to the piston rod of the oil cylinder 1, the piston rod of the oil cylinder 1 tilts towards the front of the vehicle, and the angle formed by the piston rod and the vehicle beam 11 is 5-65°;

[0027] The bottom of the vehicle beam 11 is provided with a slideway 10, and a slide block 13 is clamped in the slideway 10, and the oi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com